New Walter drill is Xtreme - carbide insert dimensions

As another example, McConnell pointed to guide bushings for deep hole drilling. “In the past, these would have been carbide or a hardened steel. Now we’re making them out of ceramics and they last 20 times longer. So the possibilities are sort of limitless.”

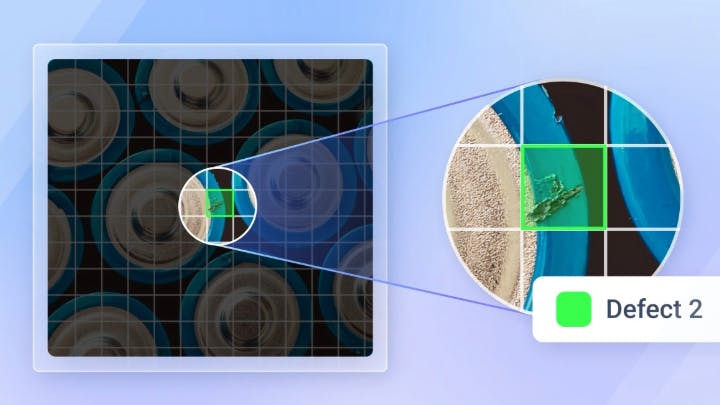

Using the DENKnet, Xactools built a series of algorithms to complete the handling and inspecting processes.

Development of breakthrough carbide-grade opportunities in machining is practically tapped out, according to Bernie McConnell, executive vice president, commercial, of Greenleaf Corp., Saegertown, Pa.

In general, inspection at the company takes place three times during the production process: after sintering, after grinding, and at the end before they are packaged into pallets bound for a customer.

Next, the first Epson robot picks up each insert separately and holds it over a second camera—also an area scan camera. Based on this image, algorithms determine the contour of the indexable insert and if there are defects on the bottom of the insert.

The indexable inserts are arranged on crucibles, or round trays, when they enter the sintering oven. The trays, which can withstand the heat and pressure of the sintering oven, are about 400 mm in diameter and about 3.5 kg in weight when they are empty.

The Scandinavian manufacturer has nearly one hundred geometry families, or subcategories, within those basic shapes, or about 2,800 different types of indexable inserts.

To help solve the problem, Better Edge reached out to David Ginzburg, who is the president of Elberton, Ga.-based Toolgal USA Corp. Ginzburg advised trying the newer RM769G hybrid-fluting bond. That might have seemed counterintuitive, because RM769G is a softer bond, but it actually worked better and delivered longer wheel life. According to Ginzburg, the wheel’s different diamond quality and the bond’s better diamond retention was more free cutting and suitable for fluting ceramic. Cycle times were just a bit slower than carbide, roughly a half-hour per tool, Shaffer added.

Using these images, algorithms also detect all pins or recessed spaces in a pallet to determine if any of them are damaged. If they are, they will be skipped in the palletization process.

The price difference can easily be 25-30%, he added, citing the case of a whisker-reinforced ceramic having a seven-minute tool life, versus six minutes for the SiAlON. But, with a 25% lower price, that works out to a 7% savings in favor of the SiAlON. “Over a year of usage, that’s a huge savings,” Navarrete asserted. “Ceramics aren’t cheap.”

The robot puts parts that do not pass inspection into a drawer so that human workers can retrieve them.

Software from Xactools also communicates with the manufacturer’s enterprise resource system from SAP (Walldorf, Germany) to find out what type of insert will be in the next load to go into the inspection system.

To solve this problem, Xactools built two gripper stations (one for each type of gripper) and created an automated process, allowing robots to change grippers as necessary.

Other machine vision components include a 1 x 1 m LED lighting screen from Planistar Lighting Technology GmbH (Himmelstadt, Germany) and a multi-GPU computing stack and industrial monitor that sit directly outside the system.

In the next step, the robot places the insert on a magnetic nest located at the first station at the rotary table. The nest is a flat surface with a magnet underneath that holds the indexable inserts in place.

Another plus: SiAlONs are “much more forgiving than a whisker,” he continued, and as a result they can run at lower speeds, without the plasticization that is normally required for whisker ceramics to cut. “If I had a part with an interrupted cut, like a forging with a scale or any type of crust, I would run a SiAlON, as opposed to a whisker.”

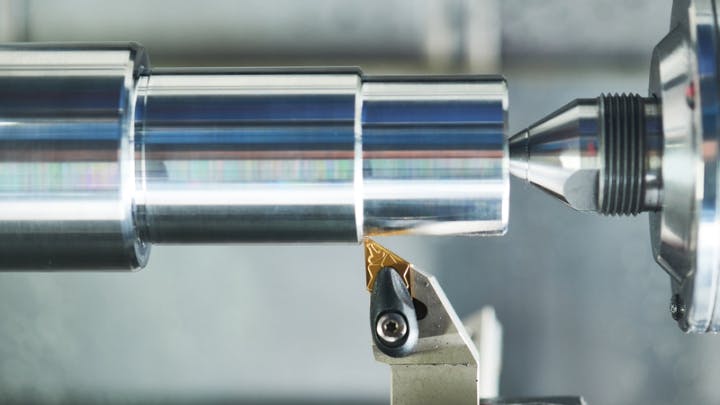

The indexable inserts are screwed into a tool holder, and many of them have a fixing hole in the center to ensure a tight hold. When the cutting edge becomes dull, the insert can be flipped to expose a new edge, or it can be replaced with a fresh insert.

Indexable inserts come in 16 basic shapes and countless varieties within each shape category due to deviations in size, thickness, cutting edge, surface finish (matte, shiny, reflective), color, and material composition (carbide, metal).

Algorithms recognize and classify each indexable insert as OK or NOK. Even tiny defects and irregularities, such as cracks or scratches, are classified as NOK.

A 2021 Manufacturing Engineering article on carbide tools, “An Improbable but Powerful Solution,” included the curious fact that ceramic inserts can look like hell and still cut well. The key to this capability, Navarrete explained, is the condition of the edge. “There is so much heat thrown into these inserts, especially if you’re running them dry, they look burnt. But the edge prep is still there. You might take it out and observe that it’s dark or charred, but once you start to cut again, it burns off—you could almost say—like a barbecue grill. Once the machining temperature threshold is reached, material residue heats up and comes off the ceramic and the edge prep is engaged again.”

“Initially, we were using a Toolgal wheel with a harder, high-performance hybrid bond, RM644, our ‘go-to’ bond when looking for longer wheel life for fluting. But in fluting ceramic tools, it was wearing faster than we would have liked.”

The team used about 15-20 images for each of seven basic geometries and then additional images showing different variations within each geometry family as well as different defects of the top, bottom, and cutting edge of the inserts.

In general, the higher hot hardness of whisker-reinforced ceramics, versus SiAlONs, enables WG300 to run in heat-resistant alloys at 10 to 20% higher speeds, but at a reduced feed rate, which is required for finishing, according to Bronson. “Our coated WG600 would go another 20% faster, so you’d be about 30-40% higher than a SiAlON. And our nano-coated WG700 is another 20% faster, so you’d be close to 50-60%. You can run in Inconel with WG700 as high as 1,500 SFM, and SiAlONs are going to melt long before you get to that point,” Bronson said, adding that WG700 also excels in interrupted cutting of Rene.

The automation and machine vision integrator, which develops measuring and testing solutions, designed and installed the custom solution in 2022 for a prominent manufacturer of indexable inserts based in Scandinavia.

Greenleaf’s first foray was removing 31-35 HRC Haynes 282 printed on a stainless steel plate. Owing to the part configuration, the print required a highly variable set of gates, risers and support structures, Bronson recalled. “Some of them were thick, some thin. Some were tall. They were all over the place. So, by nature, it was very interrupted. Plus, Haynes is very abrasive.”

Xactools’ team programmed a “look up” table into the software to describe what gripper to use for each geometry.

Despite having no previous experience with ceramics, the company worked through the required deviations from its carbide methods quickly. There were just two problems. The first, explained Brian Shaffer, vice president of operations and quality, was wheel wear.

The total cycle time per indexable insert is four seconds and the system detects defects as small as one thousandth of a millimeter.

Although there are more than 100 geometry families, the training went smoothly, Krebs says. Because the DENKnet software is already trained on underlying features of basic shapes, Krebs and his team trained the neural networks with a small number of images.

Such printed parts are usually cut off the build plate with wire EDM, leaving 0.200-0.300" (5.08-7.62 mm) of support structure to remove, Bronson said. “Then they want to clean up the base plate so they can print again. So they’ll take 15 or 20 thou off the plate.”

We want to find a TIC where we can then safely index each time and know it’s not going to fail. Milling can be anywhere from seven to 10 minutes, predictably.”

After the crucibles come out of the sintering oven, employees load them onto a lift and a motorized mechanical handling system stacks the crucibles inside Xactools’ machine vision system. The mechanical system then takes a crucible out of the stack and brings it to the robot unloading area.

Inside the enclosure, there is a rotary table with three nests, or workstations, and two Spider RS4 550 mm Series four-axis, SCARA-type robots from Epson (Suwa, Japan). The solution also includes a total of eight cameras (both line scan and area scan models) with resolutions between 5 and 30 MPixels from several manufacturers. All lens for the area scan cameras have a fixed focal length.

This helps the image-analysis algorithms determine where on the pallet the insert should go, so the second robot can place it precisely on pin or recessed space on the pallet.

Indexable inserts are used in machining operations to remove material from a workpiece by cutting, drilling, or shaping. The inserts are made of hard materials such as metal or carbide, so they can withstand the machining process.

Dillaman added that many aerospace companies perform sonic testing on their heat-resistant alloy parts, checking for minor imperfections in the surface. But in every case he knows of, “the surface finish left by a SiAlON will not pass sonic testing, whereas our WG300 and coated WG600 whisker-reinforced ceramics have been approved for this testing. So there are definitely some areas where whiskers are not going to be replaced by a SiAlON.”

As mentioned earlier, ceramics can also serve as wear parts, or other components that must survive tough conditions. Greenleaf operates a “technical ceramics” division for such applications, and trains its tooling staff to keep an eye open. McConnell said one engineer recently noticed an operator changing out the carbide guide wheels on the measuring device for a large roll-turning mill. This gauge must continuously ride along a huge steel surface, measuring roundness and size, so there is significant wear. As a solution, Greenleaf offered the customer ceramics that last 10 to 15 times longer.

As a result of the large variety of inserts to inspect, designing the system was challenging in several ways.

The solution from Xactools is a multi-station system housed inside a glass enclosure that is 3 x 3 m in size.

“Outside of doing different things with coatings, geometry, and edge preps, there are only so many ways you can mix and blend the carbide materials,” he said. “Most of the exciting technology development is coming on the ceramic side of the business.” That’s for both cutting tools and parts. “Whether you are talking about going super fast, facing extreme heat, or abrasive wear characteristics, ceramics are pushing the envelope in diverse applications. Today’s ceramic capabilities are unbelievable, and continue to get better.”

“Many people don’t appreciate how tight the dimensional and form tolerances are on these parts,” observed Daniel Rey, president of Danobat distributor Rey Technologies, St. Charles, Illinois. “And one reason Overbeck has been successful in meeting them is by using solid natural granite as a machine base. Among other things, this manages any temperature fluctuations in a shop. Overbeck also uses linear motors, which is another edge over some of the competitors.”

Of course, all this depends on having the proper edge prep to begin with. “For finishing cuts in high-temp alloys, we’d spec out a honed edge,” Navarrete said. It’s the most free cutting. For “intermediate cutting, like semi-finishing or semi-roughing, we’d go with a chamfer, which we call a T-land. It’s a little stronger. If it’s purely roughing, with a lot of material coming off, or we’re going to machine scale or crust, we go with what we call a TE edge prep. That’s a chamfer and a hone. It’s an even stronger edge, but it also means more tool pressure. It’s meant to take the beating.”

Greenleaf’s GF1 chip form also contributes to finishing success. The form is ground into the top of the insert, up to the cutting edge, and is offered on all Greenleaf’s whisker grades. “It helps reduce cutting pressure, which reduces the chance for any type of failure during the quality inspection,” Dillaman said.

However, parts that are OK need to be placed on a pin pallet or a nest pallet, so they can exit the inspection system and continue to the next step in the manufacturing process.

Xactools (Bönnigheim, Germany) designed an automated system—using machine vision and robotics—to handle and inspect indexable inserts, also known as changeable cutting edges.

Rather than worry about the misleading appearance of the insert, or focusing your attention on the edge, Navarrete recommended simply setting a time limit. “Ceramics are very shock sensitive, but also predictable.” He suggested starting with a relatively short, programmed time in cut (TIC) and then inspecting the edge. “I typically start with three and half minutes as a starting gage point. Once we find a sweet spot where everybody is comfortable, we can adjust accordingly by either adding or decreasing the insert time in cut.

At this station, there are two positions, so two pallets can be positioned side-by-side with an area scan camera positioned above each pallet.

First, robots need different grippers, depending on the geometry of the indexable insert and the type of crucible. For example, some crucibles have long slots embedded in them to hold rectangular inserts while others have pins to hold round inserts.

The newest call for ceramic cutting tools comes from the need to clean up the build plates after metal 3D printing. Bronson listed cobalt chrome for medical products, Inconel 718 for aerospace, Haynes 282 for rocket engines, Rene 220 for power generation, and Rene N2 as difficult alloys the company is being asked to deal with. These are difficult to machine materials when forged, and Bronson explained that printing them adds another degree of difficulty because the laser-sintering process leaves scale between the layers.

In addition, Danobat’s Beavers said paying the “utmost attention” to the thermal stability of the machine means incorporating liquid cooling in the workheads. Coolant filtration also must be at “the highest level,” he said. So, in addition to a standard system, the company adds canister filters rated down to five microns, plus chillers to maintain a constant temperature.

What’s more, where the abrasive nature of the material had forced the customer to take very shallow depths of cut, amounting to only 0.015" to 0.025" (0.38-0.635 mm), Greenleaf increased the depth of cut to between 35 and 50 thou. “And instead of having to take maybe five, or six or seven passes with carbide, we can take two or three with ceramics and clean up the entire plate,” Bronson said. In fact, on six such projects on which he’s worked, edge damage usually required indexing the carbide tool after a single pass through the laser-sintered material. Whereas the ceramic “lasted through every pass we had to make,” Bronson observed.

Once positioned at the second station, two line-scan cameras, one positioned on the top and a second on the side, scan the cutting edge of the insert as it is rotated. Each camera also moves as needed to make sure that the cutting edge of the indexable insert is always within the focal plane of the camera.

Danobat conquers these challenges with its Overbeck IRD machine, equipped with a four-spindle wheel head. Grinding the form requires three-axis interpolation (X, Z, and B0), as well as all four spindles. For example, grinding the outside of the form requires a large OD wheel, while much smaller ID wheels tackle the inner form. Getting the required surface finish also necessitates using multiple abrasives for roughing as well as finishing, added Beavers.

“That beats up carbide significantly. You get a lot of chipping and excessive wear. So customers were hoping ceramics could get through that.”

If you need a third example, you can’t do much better than a line that produces 2,000 aluminum beverage cans per minute. According to Jim Beavers, sales manager for Danobat Group in Rolling Meadows, Illinois, the necking die that forms the can’s walls to accept the lid was traditionally made of carbide, “but over the years, they’ve discovered that HIP (hot isostatically pressed) ceramic has a longer life, because they have better heat transfer and wear capability.” The version Danobat sees most often is yttria tetragonal zirconia polycrystal (YZTP), which Beavers reported as “coming in at 81 on the Rockwell scale, and 1,300 on the Vickers. So certainly a challenging material.”

Linda Wilson joined the team at Vision Systems Design in 2022. She has more than 25 years of experience in B2B publishing and has written for numerous publications, including Modern Healthcare, InformationWeek, Computerworld, Health Data Management, and many others. Before joining VSD, she was the senior editor at Medical Laboratory Observer, a sister publication to VSD.

However, he pointed out, the fragility of ceramics is often exaggerated. “Ceramics can take a beating, you just have to program it and approach it properly.” On that note, he cautioned, any switch from carbide to ceramic tooling requires reprogramming the cut. “You should not plug a ceramic tool into a carbide program.”

While chemically similar to a SiAlON, Greenleaf’s well-known XSYTIN-1 ceramic is a phase-toughened silicon nitride. “The way it’s pressed causes a crystalline structure to grow inside the material,” Bronson explained. As a result, he said, the company can “generally run 20-30% higher feed rates with XSYTIN-1 than most SiAlONs,” even though XSYTIN-1 has a similar speed limit, because the binders break down at a similar temperature.

Greg Bronson, Greenleaf’s sales director for the Americas, elaborated. “Because the edge of whiskered-grade ceramics holds up better, you don’t get the same level of heat generation and the smearing of material that could cause parts to fail additional surface testing.”

To facilitate palletizing, the robot, with an indexable insert in its gripper, moves over a camera located above a pallet—either a pin or nest variety. The camera snaps an image, which provides visual information about the contour of the insert and the position of the hole in the center of it. The robot then holds the insert over a camera located below it to get final positioning information.

While some traditional machine vision algorithms are used in the solution, most of the image analysis is enabled with convolutional neural networks, which Xactools developed using DENKnet, AI-based image evaluation software from IDS Imaging Development Systems GmbH (Obersulm, Germany).

Iscar offers “tough” SiAlONs and “hard” versions. The latter is advertised as “whisker-like,” because it mimics the hard, brittle nature of whisker-reinforced ceramics.

Before the adoption of the automated solution, the manufacturer relied on a manual spot-checking process of a statistical sample of parts per production order.

That’s not all. The die has a fairly complex form, inside and out, plus a slot. “The profile tolerance is two tenths. And the other important aspect is the tangency on the radius versus the angle where they intersect,” explained Beavers. It gets worse. “Customers are requesting the inner bore come from the machine down to two micro inches. So we have to deliver a polished finish.”

But this isn’t anything new. Navarrete noted that a number of shops are familiar with these capabilities based on experience with whisker-reinforced ceramics, which is a decades-old technology. Instead, he touted newer silicon, aluminum, oxygen, nitrogen (SiAlON) ceramics. “You can run the same whisker-like parameters at a lower cost, because SiAlONs are cheaper to produce than whiskers,” Navarrete said. “I’ve never gone into a shop, spec’d out and quoted a SiAlON and been more expensive than a whisker. It hasn’t happened.”

Indexable inserts, which come in many shapes, are manufactured using a sintering process in which powdered metals and other materials are pressed into a shape and then sintered, or bonded together, using heat and pressure.

“For milling, I’d typically start at around 3,400 SFM, gauge the wear on the insert and adjust the parameters accordingly,” he explained. “For turning, depending on machine capability, you’d be between 600 and 1,100 SFM in high-temp alloys.”

So, there you have it. Ceramics offer outstanding solutions to difficult machining challenges, and the challenge of machining ceramics themselves can also be met with the right technology and a willingness to push the limits.

Meanwhile, Greenleaf’s premium performance whisker-reinforced ceramics continue to have value-added applications, owing to their higher hot hardness and wider feed-rate capabilities, according to Martin Dillaman, the company’s global manager for engineering and applications. For example, he said, “you typically would not finish with a SiAlON in heat-resistant alloys, because they run at a higher feed rate that exceeds the surface finish requirement for the part. So you have to use a whisker-reinforced ceramic if you want to keep the speed up and finish.”

However, the neural networks were eventually able to recognize and categorize indexable inserts and any damage without new training images. "The system has been running for six months and the self-learning, global AI now recognizes parts that it has never seen before,” Krebs says.

Once the robot deposits the insert on the magnetic nest, it moves out of the way, and a third area scan camera moves into position above the station and snaps an image of the insert. From this information, algorithms analyze the top of the insert for defects, its position from X and Y coordinates, and rotation information.

The second problem with grinding ceramic is that it produces a fine, milky swarf that clogs coolant filters faster than carbide. Better Edge addressed this by changing filters more frequently, but decided that if they were to continue grinding ceramic they’d have to dedicate a filter to that application.

Neither Greenleaf nor Iscar shares the secrets of how their tools are made. But Scottsdale, Pa.-based Better Edge gives a glimpse into the challenge of grinding the final cutting geometry. While the company focuses on specialized carbide cutting tools, Better Edge recently got a project to grind a half-inch diameter, short-LOC, six-flute end mill for an aerospace customer. The tools came in worn, so Better Edge cut off the cutting portion, then ground a new geometry into the remaining blank.

Ceramics remain an excellent solution for high-temp alloys and abrasive materials, with the ability to achieve eye-popping rates. In fact, milling speeds in high-temp alloys range from 2,800 to 4,400 surface feet per minute (SFM), according to Robert Navarrete, national product specialist for parting, grooving, and turning at Iscar USA.

Oddly, he added, the softer stainless material presented an even bigger challenge for carbide. Once a tool designed for the tougher material hit the stainless steel, it would fail. That’s probably because the gumminess of the stainless steel inhibited chip formation. Greenleaf’s solution was to use the XSYTIN-1 ceramic in a small face mill with RNG45 inserts. The strength of XSYTIN-1 allows the user to “get away with a sharper edge,” Bronson said. “That allows you to get through the hard material, yet it doesn’t smear in the softer material, thanks to the sharper geometry.”

Since Xactools installed the system at the Scandinavian manufacturer, engineers have been working on version 2.0, which includes a more compact enclosure among other updates.

To inspect the indexable inserts, Xactools developed an automated process that occurs right after sintering. "The earlier defects are detected in the process, the better and cheaper it is to rectify them," says Marvin Krebs, managing director at Xactools.

After the sintering process, the cutting edges of the inserts are refined by rounding them and then grinding, blasting, and coating them.

Here, an area scan camera takes an image of the entire tray, providing data so that an object detection algorithm can locate each indexable insert on the tray. Another algorithm analyzes the image data to provide grabbing points for the robot.

18581906093

18581906093