Parting & Grooving: Advanced Tech Delivers Quality Parts, Results - carbide insert parting tool

If you find this article informative, consider subscribing digitally to Aerospace Manufacturing for free. Keep up to date with the latest industry news in your inbox as well as being the first to receive our magazine in digital form.

Connect with the manufacturing community and supply-chain across 3 days at the UK’s leading annual industrial event.

These tools can ramp up to 8.8 degrees and a maximum 0.642-in. depth of cut. They are available in shell mills, screw-on cutters, cylindrical shank, and Weldon shank end mills with internal air and coolant capability.

The cutter bodies have an integral chip gash for chip evacuation, along with a hardened-steel construction and hardened pocket seats, which provide high resistance to deformation.

Pensett Trading Estate DY6 7NP UNITED KINGDOM

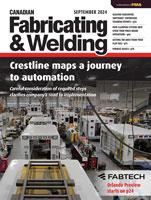

Easily access valuable industry resources now with full access to the digital edition of Canadian Fabricating & Welding.

FIX8 has eight cutting edges per insert, providing the lowest cost per edge. The tangential design allows it to sustain far higher loads than traditional designs.

The FIX8 is said to provide excellent chip control for any heavy-duty turning application while increasing tool life. The insert design reduces cutting forces and power consumption, making it ideal for any low horsepower lathe.

With eight cutting edges per insert, the FIX8 turning system increases productivity of any heavy-duty turning operation, providing the lowest cost per edge while reducing cutting forces up to 15%.

Kennametal has released the FIX8 heavy-duty turning system, delivering maximum metal removal rates in steel, stainless steel and cast iron. With eight cutting edges per insert, the FIX8 turning system increases productivity of any heavy-duty turning operation, providing the lowest cost per edge while reducing cutting forces up to 15%. FIX8 has eight cutting edges per insert, providing the lowest cost per edge. The tangential design allows it to sustain far higher loads than traditional designs. “FIX8 is designed to cover a wide range of applications, including turning and facing, smooth surfaces, interrupted, and heavily interrupted cuts. From medium depth-of-cut to roughing in steels, cast iron, and challenging materials like stainless steel, FIX8 handles it all. Even extreme feed rates of up to 1.4mm (0.055") and depths of cut up to 12mm (0.472") are possible with FIX8,” says Matthew Fuerst, product manager, Kennametal. The tangential design of the FIX8 insert features a rigid clamping system that pulls the insert securely into the pocket seat, offering superior stability that enables the insert to withstand large cutting forces and vibrations for optimal performance. The insert is also supported by a replaceable carbide shim, protecting the pocket against deformation and damage. The FIX8 tool holder features precision 3D coolant technology, supplying sufficient coolant precisely where needed. Three coolant nozzles are directed to the rake face, controlling temperature, chip evacuation, and supporting chip formation. Coolant exit holes in two different locations are directed toward the flank of the insert, controlling the heat in the cutting zone and prolonging tool life. The FIX8 is said to provide excellent chip control for any heavy-duty turning application while increasing tool life. The insert design reduces cutting forces and power consumption, making it ideal for any low horsepower lathe. www.kennametal.com

The inserts have strong cutting edges, multiple corner radii, and positive rake faces that provide a true 90-degree wall while providing excellent wall and floor surface finish, the company states.

ANT Industries, a leading manufacturer of aero engine and gas turbine components in Atherstone, Warwickshire, has announced a significant milestone in its commitment to quality and excellence.

Widia has released the Victory Shoulder Mill (VSM) 17 platform for shoulder milling, profiling, face milling, slotting, ramping, helical interpolation, and circular interpolation.

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

“FIX8 is designed to cover a wide range of applications, including turning and facing, smooth surfaces, interrupted, and heavily interrupted cuts. From medium depth-of-cut to roughing in steels, cast iron, and challenging materials like stainless steel, FIX8 handles it all. Even extreme feed rates of up to 1.4mm (0.055") and depths of cut up to 12mm (0.472") are possible with FIX8,” says Matthew Fuerst, product manager, Kennametal.

The FIX8 tool holder features precision 3D coolant technology, supplying sufficient coolant precisely where needed. Three coolant nozzles are directed to the rake face, controlling temperature, chip evacuation, and supporting chip formation. Coolant exit holes in two different locations are directed toward the flank of the insert, controlling the heat in the cutting zone and prolonging tool life.

Kennametal has released the FIX8 heavy-duty turning system, delivering maximum metal removal rates in steel, stainless steel and cast iron.

The tangential design of the FIX8 insert features a rigid clamping system that pulls the insert securely into the pocket seat, offering superior stability that enables the insert to withstand large cutting forces and vibrations for optimal performance. The insert is also supported by a replaceable carbide shim, protecting the pocket against deformation and damage.

Easily access valuable industry resources now with full access to the digital edition of Canadian Metalworking.

The Ultralift Plus is a lightweight, safe, and easy to operate lifting magnet. Engineered to lift and transport materials without slings, hooks, or chains. Complete with the patented 'Safety Shim' - allows pre-testing of any load to ensure a 3:1 safety factor, guaranteed.

18581906093

18581906093