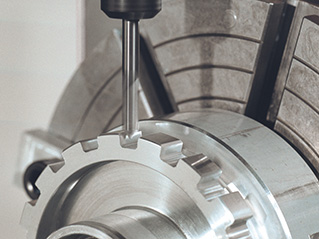

[YG-1 Indexable Inserts]YG-1 Launches the New Turn-Groove ... - grooving insert name

We are passionate about the products that we manufacture, import, and distribute but also devoted to its context, whether it’s a kitchen countertops, bathroom vanity top, floor, or wall application.

This program is for a 1.0" diameter hole with a cutter diameter of 0.500" and a thread pitch of 0.125 (8TPI). This program positions itself in Absolute G90 and then switches to G91 Incremental mode on line N7.

Circularinterpolation formula

The next step is to program a complete circle (G02 or G03) with a Z-Axis command of the amount of one full pitch of the thread (this is called Helical Interpolation).

Helix CNC Finger Bit 2cm is a type of cutting tool with several cutting segments arranged in a cylindrical shape that resembles fingers.

Haas G13 example

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Helix CNC Finger Bit 3cm is a cutting tool used for accurate milling or shaping activities in the stone fabrication industries.

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

Circularpocketmillingprogram Fanuc

They significantly increase production speed and consistency while ensuring superior quality of the finished products. Automation lowers labor costs and the risk of human error, making processes safer and more affordable. CNC tools also provide flexibility in manufacturing since they can be reprogrammed quickly and easily for different tasks. This supports the use of various materials and allows for the creation of delicate designs, expanding the possibilities in manufacturing.

Circularinterpolation in CNC

Helical (spiral) motion is possible with G02 or G03 by programming the linear axis that is not in the selected plane. This third axis will be moved along the specified axis in a linear manner, while the other two axes will be moved in the circular motion. The speed of each axis will be controlled so that the helical rate matches the programmed feedrate.

CNC tools are extremely useful in the automotive, aerospace, electronics, and woodworking industries. They are ideal for large manufacturers and small workshops aiming to boost productivity and quality. Educational institutions also use these tools to provide hands-on training in manufacturing technologies. Whether you're an experienced engineer or a beginner, these tools are simple to use with basic training, turning complex manufacturing tasks into manageable projects.

CNC tools are manufacturing equipment designed to improve accuracy in cutting, milling, drilling, and turning processes. They operate automatically by following programmed instructions, which reduces the need for manual intervention and minimizes errors. Due to their sturdy construction and advanced technology, These tools are necessary for producing delicate parts. They ensure great quality and effectiveness, making them an excellent asset for modern manufacturing processes.

Millinga circle manually

Use a G03 to cut I.D. threads or a G02 to cut O.D. threads. An I.D. right hand thread will move up in the Z-Axis by the amount of one thread pitch. An O.D. right hand thread will move down in the Z-Axis by the amount of one thread pitch. PITCH = 1/Threads per inch (Example - 1.0 divided by 8 TPI = .125)

To cut a full circle the I, J, K addresses must be used; using an R address will not work. To cut a full circle, do not specify an ending point (X, Y, and Z ); program I, J, or K to define the center of the circle. For example:

You cannot turn cutter compensation off or on during an arc movement. You must program a linear move, either in the X or Y Axis, to move the tool to and from the diameter to cut. This move will be the maximum compensation amount that you can adjust.

Circularinterpolation feed rate calculator

CircularInterpolation calculator

To start, take the hole diameter (1.500). Subtract the cutter diameter .750 and then divide by 2. (1.500 - .75) / 2 = .375

After the initial positioning, the next step of the program is to turn on cutter compensation and move to the I.D. of the circle.

The use of an Lxx value on line N10 allows us to repeat the thread milling arc multiple times, with a Single-Point Thread Mill.

I, J and K address are used to locate the arc center in relation to the start point. In other words, the I, J, K addresses are the distances from the starting point to the center of the circle. Only the I, J, or K specific to the selected plane are allowed (G17 uses IJ, G18 uses IK and G19 uses JK). The X, Y, and Z commands specify the end point of the arc. If the X, Y, and Z location for the selected plane is not specified, the endpoint of the arc is the same as the starting point for that axis.

These G codes are used to specify circular motion. Two axes are necessary to complete circular motion and the correct plane, G17-G19, must be used. There are two methods of commanding a G02 or G03, the first is using the I, J, K addresses and the second is using the R address.

Circularinterpolation program example

Investing in CNC tools is a smart move for businesses looking to improve their manufacturing capabilities. Explore the possibilities and take your production to a new phase with accurate engineering. Reach out to us to learn more about our products and the various ways you can acquire them.

The R-value defines the distance from the starting point to the center of the circle. Use a positive R-value for radii of 180 or less, and a negative R-value for radii more than 180.

Thread milling uses a standard G02 or G03 move to create the circular move in X-Y, then adds a Z move on the same block to create the thread pitch. This generates one turn of the thread; the multiple teeth of the cutter generate the rest. Typical block of code:

0086-813-8127573

0086-813-8127573