Why More Flutes Aren't Always Better: Understanding the ... - end mill 2 flute vs 4 flute

2022720 — Now that doesn't mean that Titanium is soft, they are both very hard material, but Steel is harder. So even if you can make Titanium as easily ...

Raytheon shipped the robot from Tucson to the innovation lab on ASU's Polytechnic campus in Mesa. The industrial corporation chose to use the university's eProjects program, which brings students and industry together to solve real-world problems. Industry partners fund project expenses and receive full access to the results.

“You’re bringing together multiple disciplines from engineering — management, global supply chain — and scheduling weekly industry partner meetings,” he said. “We kept them in the loop, and they kept us in the loop.”

In a dazzling feat of technical know-how and tireless dedication, the student engineers had the deburring robot up and running in 60 days. It dominated the students' schedules.

“We may be the first capstone project to have middle management,” Chicci said. (Capstone projects are senior-year projects that require students to draw on everything they have learned. Chicci graduated with a BSE in robotics.)

Find the best Paper Punches for your project. We offer the Paper Corner Rounder 3 in 1 R4mm+R7mm+R10mm Punches for Crafts Cutter Envelope Punch Board ...

The robot works at eye-blink speed when it’s throttled up. It’s actually a little eerie to see something so huge move so quickly, smoothly and precisely.

EDIT: For anyone still reading this, despite Carbide 3D being extremely responsive publicly on social media about finding a solution, none of the techs have further contacted me or provided any next troubleshooting steps. I have responded immediately to all requests for info and pictures from multiple techs only to be completely ignored afterward. I am returning this machine and saving money to buy a more powerful fiber laser that can cut thin metal.

This section provides an overview for carbon fiber-reinforced plastics (cfrps) as well as their applications and principles. Also, please take a look at the ...

Defense contractor Raytheon had a $350,000 robot arm, used for smoothing the rough edges of metal, but it wasn't complete.

KAGYIFLY

The robot arm was mounted in the top of the table, but it couldn’t reach everything. When the robot was lowered below the surface, it “thought” everything that was on the table was now in the table. The team had to figure out the mess. The challenge? Make it dance and get chips flying. At times it felt like starting from scratch might have been easier.

Oct 24, 2019 — So, hardness in the other words can be defined as the ability of any metal to resist notch. It is the resistance to indentation or notch. The ...

Looking for recommendations for a desktop CNC mill to cut 0.1 - 1.0mm sheet brass or aluminum to make various watch parts such as dials and hands. Some precision is required due to the small nature of the parts (I'd be making stuff like 28mm circles with 5x2mm rectangle cutouts, or like, a small 4mmx4mm airplane shape to stick onto a seconds hand). None of these parts are functional so I wouldn't need extreme accuracy. I'm looking for recommendations in the $2,000 USD and under range, and have considered cheaper Amazon machines by Foxalien and Genmitsu, but wanted to hear more opinions on this.

ChipsFly router lift

“They were really impressed because we found a lot of issues,” said Marcos Valenzuela, who graduated with a BSE in mechanical engineering.

Top photo: The robotic arm goes through its paces at the Innovation Hub on ASU's Polytechnic campus on May 17. Raytheon delivered the nonworking deburring robot to ASU in hopes that it could reprogram the device after the former integration company failed. In the 60-day time frame, engineering students were able to program, run and test the massive arm. Photo by Charlie Leight/ASU Now

Climb milling – chips are evacuated behind the cut so that you are not re-cutting them which results in a better surface finish.

Woodworking Square Set

Every year, a legion of hackers, programmers, cybersecurity professionals and researchers descend on Las Vegas for the most storied convention in the hacker community: DEF CON.Since 1993, the…

However, in life and engineering, “you’re not always starting on something from scratch,” said Rebecca Bell, who earned her BSEBachelor of Science, Engineering in robotics this spring. “We had a lot of debugging to do. It was diving in to see what the current state was and how to solve the problems.”

On an airplane, motions of air on both small and large scales contribute to turbulence, which may result in a bumpy flight. But turbulence on a much larger scale plays an important in how stars form…

Nearly 14 billion years ago, a mysterious energy sparked the Big Bang, causing the universe to expand rapidly and generating all known matter — a process described by the inflationary universe theory…

Recent robotics and manufacturing engineering graduates Jesse Wittkowski (left) and Riley Chicci watch the Kuka robotic arm perform functions. Photo by Charlie Leight/ASU Now

Taytools

Budget router lift

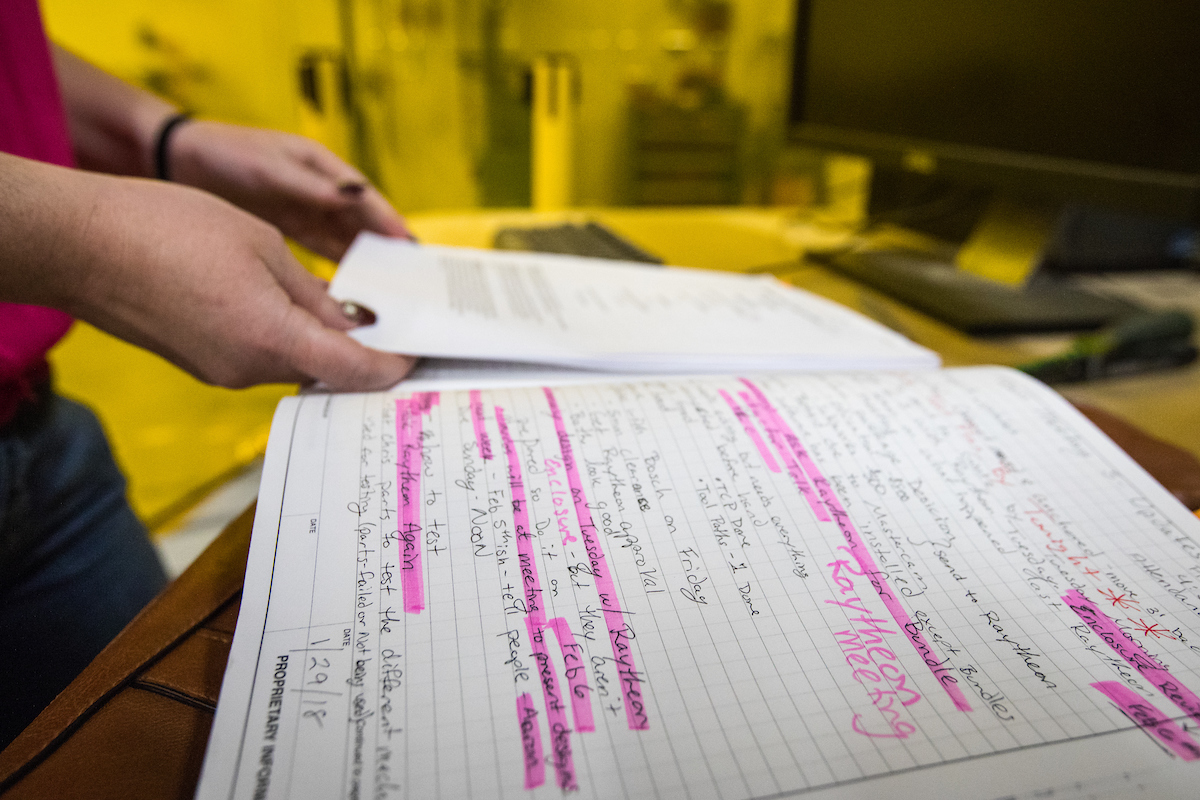

Recent robotics engineering graduate Rebecca Bell reviews her engineering notebook, called "The Bible" due to her meticulous notes on all meetings and all work done on the robotic arm. Photo by Charlie Leight/ASU Now

2018515 — To maintain tolerances, start first by testing the runout of both your machine and your tool. This simple, yet often overlooked step can save machinists a ...

I also have an Xtool IR 2W fiber laser engraver which I use to etch and mark parts. However, it seems that actually cutting thin metal with a fiber laser is a huge step up from this and a machine like this would likely cost $5,000 at a bare minimum. The laser groups I'm in have suggested getting a cheap CNC mill to accomplish sheet metal cutting.

“We had placed the robotic deburr project in storage at Raytheon after one of our suppliers could not complete development,” said Chad Spalt, a missile systems engineering fellow at Raytheon. “The ASU Polytechnic eProject program was an affordable way for us to continue technical development on the project, while building a stronger relationship with the ASU Polytechnic campus. The students solved a number of technical issues, and the robotic work cell will soon be slated for use in an industrial working environment.”

Sandhog Tungsten Carbide Insert Turning Inserts offered by China manufacturer Sandhog Tools. Buy Sandhog Tungsten Carbide Insert Turning Inserts directly ...

Porter Cable router lift

For Dolgin, his learning curve was managing the group. “It was being able to coach them through the waiting periods,” he said. “It was no small task.”

“It was just as much a project dealing with Raytheon and ASU as much as the robot,” he said. “I don’t mean that in a bad way. It was just getting an organization as big as Raytheon and an organization as big as ASU to meet in the middle was not easy.” Doucette graduated with a BSE in mechanical engineering systems.

The robot is huge. It’s like the Incredible Hulk’s arm, but made of orange metal. Together, the robot and the table it’s mounted on weigh 13,000 pounds — as much as an African bush elephant. The arm, which can hold 120 pounds and reach a little over 6 feet, machines parts to aerospace tolerances (think one-15,000th of an inch).

“I was either in class, here, or on the toilet,” said Jesse Wittkowski, who graduated this spring with a Bachelor of Science, Engineering in robotics and manufacturing.

Our advanced machining capabilities include 4-axis and 5-axis milling, swiss machining, and even micromachining. This allows us to create the highest precision ...

Router lift for Bosch 1617

iGaging 4 square

Up milling, in which the workpiece is moving towards the cutter, opposing the cutter direction of rotation.

An internship at Northrop Grumman taught him a lot. (Dolgin now works there, after graduating last spring with a BSE in electrical engineering.)

“We plan to continue working with the ASU Poly campus to refine their manufacturing engineering curriculum and better prepare their manufacturing engineering graduates to immediately contribute when they enter the professional workforce, perhaps at Raytheon,” Spalt said.

I own a Nomad 3 which was defective right out of the box (hasn't even homed once successfully) and multiple techs from Carbide 3D support have only responded with the most basic diagnostic questions and then ignored me completely when I respond. Nobody on their forums or on Facebook have an idea of how to diagnose further either. They also don't answer the phone. It was $$$$ and was supposed to be a turnkey solution. I am returning this machine to the vendor as I am nearing the 30 day mark with no resolution.

An expertise in high-speed aluminum milling and an understanding of the three elements of tool design can make you successful in high-speed aerospace machining.

Recent engineering graduates Aaron Dolgin and Rebecca Bell talk about their work on the robotic arm at the Innovation Hub on the Polytechnic campus. Photo by Charlie Leight/ASU Now

0086-813-8127573

0086-813-8127573