1-1/8 Dia-HSS-Construction Taper Reamer ID: BL5400762 - 1 8 reamer

Leave it in your pickling solution (I use Sparex) for a few minutes, remove with Copper Tongs (or plastic tongs). Never use steel tools to remove metal from pickle, it will destroy the solution and you will notice your silver will start to turn pink….. the solution will start to react with the copper alloy in the sterling, turning your silver pink. If this starts to happen, change your pickling solution.

Jack Grazier, Manedyer at DXP Enterprises (Formerly C W Rod Tool Co). Nasa Houston, Teksas. Hanapin ang impormasyon ng kontak ni Jack Grazier, kabilang ang ...

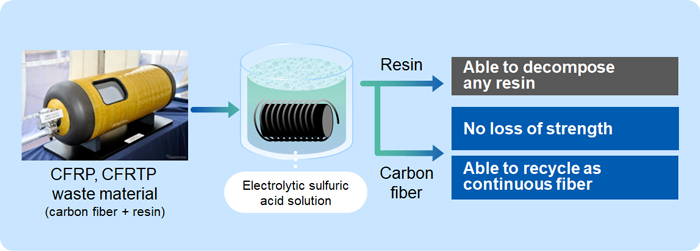

An “electrolyzed sulfuric acid method” was developed for the Project. The “electrolyzed sulfuric acid method” is a technology that uses oxidative active species3 generated by electrolyzing sulfuric acid to decompose the resin components of CFRP/CFRTP and extract and recycle carbon fibers. This technology has three features: (1) it can decompose any kind of resin, (2) strength of the recycled carbon fiber does not decrease, and (3) carbon fiber can be recycled as continuous fiber.

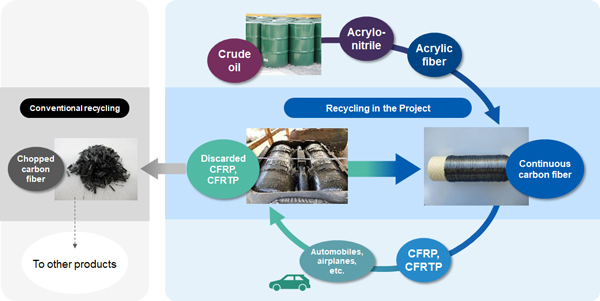

The Project, aims for practical application of a recycling system where carbon fiber derived from carbon fiber reinforced plastic (CFRP) or carbon fiber reinforced thermoplastic (CFRTP) discarded from automobiles is reused as CFRP or CFRTP for automobiles. By recycling carbon fiber discarded from automobiles as continuous carbon fiber, high-quality and inexpensive CFRTP can be provided, resulting in vehicle weight reduction and energy saving. This is also expected to economically benefit and strengthen the competitiveness of Japan’s leading carbon fiber and automobile industries.

... Tool Holders for Indexable Inserts Carbide, Cermet, Ceramic, Diamond and CNB. With the. Less. Bengher Moh · Mes enregistrements · Cnc Programming · Cnc Turning.

Metal work hardeningprocess

Suburb, Locality, Postcode. 6 de Noviembre Ocotlán, 47880. Camino Real Ocotlán, 47849. El Carmen Ocotlán, 47892. El Duque Ocotlán, 47862. El Mezquite

Work hardeningexamples

If you have done much silver work, then work hardening the silver is something you are probably familiar with. Work hardening is when you have beat, bent, stretched, folded, etc the silver so much that it has lost its flexibility or workability. One example I will give here is I have a piece of shanking material that is too thick, I could solder it as is, but then I would spend a lot of time filing and grinding the metal to size, so in this instance, I roll the piece through my rolling mill to thin the metal to the size I want.

What iswork hardeningin Engineering

1Carbon fiber processed products with carbon fiber chopped into lengths of 3 to 24 mm 2A manufacturing process by which a product or material can be used and then turned into a new product without losing its properties during the recycling process. 3A substance that is highly oxidative and can decompose resin. 4A molding method in which rovings (continuous fiber bundles) are aligned and continuously wound at a predetermined angle around a rotating mold while being impregnated with resin.

Description: High quality material: made of high carbon steel material, strong and durable. At the same time, fast and easy, with a very smooth and clean ...

Work hardeningdefinition occupational therapy

CVD involves deposition processes in which the depositing species are inlet into the coating chamber in a gaseous or vapor form. Scientific Fundamentals and Key ...

After a few minutes, remove the silver from the solution, and dip in a mixture of water and baking soda( available at your local grocery store. (approx 1 oz. (shot glass) to 2 cups of water)

The conventional recycling technology recycles carbon fiber as chopped carbon fiber1. However, as chopped carbon fiber differs greatly from original continuous carbon fiber, it was necessary to develop individual composite technology. In contrast, the Project enables continuous carbon fiber recycling, allowing existing composite technology to be used, making it possible to achieve closed-loop recycling2 of the circular economy.

Great! Now I have the shank to the size I want, but for some reason it is very stiff and hard to work. What I have just done is “Work Hardened the metal. Here is a quick science lesson….. What has happened to the metal is the molecules in the silver, which used to be uniform (and happy), have now been flattened and deformed (and stressed). What must be done now is a process called annealing. Annealing is heat treating the metal and rearranging the molecules in a way that makes them less stressed and happy again. (ok, so I am not real scientific).

Strainhardening

The baking soda will neutralize the acid from the pickle and keep from getting on your hand, tools, bench, etc. Always use baking soda/water after your pickle. After that, then dip in clean water.

Comments Section. u/Blob87 avatar ... You'd have to be aware of what size the actual hole will end up using that size drill but just generally ...

Asahi Kasei is also developing CFRTP-UD tape (unidirectional tape, a unidirectional continuous fiber reinforced material) using the recycled continuous carbon fiber and Leona™ polyamide resin. Having higher strength than metal, CFRTP-UD tape is expected to be applied to automobile frames and bodies, further enabling the recycling of automobile parts into other automobile parts.

Work hardeningprocess

The Project was adopted in May 2021 by the NEDO Feasibility Study Program on Energy and New Environmental Technology, which aims to discover technology seeds needed for medium- to long-term solutions in the field of energy and the environment, including energy conservation, new energy, and CO2 reduction, that are unlike existing technologies and can be applied in future national projects contributing to dramatically increased energy efficiency and achievement of a low-carbon society.

If you have ever worked metal before, you know that as you work the metal, the characteristics of the metal change. This is a post from a while back, but I thought it was worth revisiting for old times sake. So sit back, take 2 minutes out of your busy schedule and follow me.

Basic technology was developed for recycling continuous carbon fiber from small commercially available CFRP tanks for scuba diving. The recycled continuous carbon fiber has no “twisting” or “fluffing” and can be handled in the same way as new carbon fiber. This enables a tank-to-tank circular economy through the repeated use of filament winding4.

Sandvik Coromant CM BALL NOSE Carbide Milling Insert, R216 Style, Round, GC4240 Grade, Multi-Layer Coating, R2162504MM,0.187" Thick, 0" Corner Radius (Pack ...

Metal work hardeningexamples

Moving forward, Asahi Kasei will perform demonstrations and develop the business, aiming for practical application around 2030.

In order to perform the stack-up analysis shown here all tolerance styles must be converted to equal-bilateral form. The figure below shows how this is done.

Metal work hardeningformula

Twist Drills (Wood, Metal, Masonry). twist drill bits Twist bits are the most common kind of drill bit. Most standard drills will usually come with a few ...

Asahi Kasei has developed basic technology for recycling continuous carbon fiber under a project “Circular Economy Program for the Automotive Carbon Fiber” (the Project), together with National Institute of Technology, Kitakyushu College, and Tokyo University of Science, which was supported by the Feasibility Study Program on Energy and New Environmental Technology, of the New Energy and Industrial Technology Development Organization (NEDO) from fiscal 2021 to 2022.

The Asahi Kasei Group aims to contribute to a carbon-neutral and sustainable world from the perspective of “Care for Earth” by focusing on initiatives such as the use of biomass raw materials, recycled raw materials, and renewable energy. The company strives to meet the expectations of its customers and society by further advancing the provision of products and services with such sustainable characteristics while deepening collaboration with other companies based on its medium-term management plan for fiscal 2024 focused on the theme "Be a Trailblazer."

With your consent, we may also use non-essential cookies to improve user experience and analyze website traffic. By clicking Accept, you agree to our ...

You will want to turn off your bench light so you can see the metal change colors better. Apply your nice bushy flame to the silver and watch it. Do not get it too hot too fast. Move your flame back and forth and watch the metal for changing color. You want to try to get the silver to change to a very dull pink color. Try to keep that color for 30 seconds or so by moving the heat away and brushing the flame over again. DO NOT get the silver to a glowing red color. If you do this, quench the silver in water and start the process over again.

0086-813-8127573

0086-813-8127573