1-1/8" x 17" Simpson SDS-MAX Quad Head Concrete Drill ... - 1 1/8 drill bit

Undercuttingexamples

Gass-Shi-eldd Flux-Kored Arck Welding (GSFCAW) Gas-Shielded, Flux-Cored, Arc, Welding A welding process using an arc and a flux core wire, with an external shielding gas. Example usage: The tradesperson welded...

Choosing the right tool bit coating can make a big difference in your work as a tradesman. Here are some of the pros and cons of the most popular tool...

Undercuttingmeaning

Reload products are designed in the UK by Bambusa Ltd, registered in England and Wales number 09993647.VAT number GB 333 7752 91.

Undercuttingconstruction

SELF-SHEED-ELD FLUX-CORED ARK WELD-ING Self-Shielded Flux-Cored, Arc, Welding A welding process that uses an electric arc to join metals together while protecting the weld from atmospheric contamination. Example usage: 'We'll...

Undercut hairstyle girl

Why is the microstructure important? It is simply because many of the most important physical characteristics of a material are controlled by the microstructure. We can think how the strength of a piece of wood will differ markedly when we try and break it along or across the wood’s grain, and much the same concept applies to polycrystalline materials. All of the microstructural characteristics will profoundly affect the bulk material properties, including the strength, toughness, ductility, corrosion resistance, electrical properties and so on. So, if we want to understand or control a material’s physical properties, then we need to be able to characterise the microstructure.

Before looking at how the EBSD technique works, it is important to understand the concept of crystallinity and the term “microstructure”.

Gass-Shi-eldd Flux-Kored Arck Welding (GSFCAW) Gas-Shielded, Flux-Cored, Arc, Welding A welding process using an arc and a flux core wire, with an external shielding gas. Example usage: The tradesperson welded...

Undercutting is a critical step in welding and is essential for creating a strong, durable joint. It ensures that the weld has a good surface area for adhesion, as well as providing a good seal for the weld. This helps to prevent any gas or liquid from entering the joint and causing corrosion.

Undercut meaning in business

Ever wondered what plumbers are actually saying when they come to fix your sink or toilet? If you've ever been confused by the strange lingo they use, you're not...

Undercutting is a common welding technique used to join two pieces of metal together. It involves creating a groove along the edge of one of the pieces and then filling it in with a weld to create a strong bond. The groove is usually created using a grinding wheel or a flame cutting torch. The process can be used to join two pieces of the same metal or two different metals.

Choosing the right tool bit coating can make a big difference in your work as a tradesman. Here are some of the pros and cons of the most popular tool...

Undercuttingin a sentence

Undercutting was originally used in manual welding processes, and was done by grinding or chiseling away the weld metal. As welding technology advanced, automated methods of undercutting were developed which involved using a gouging rod or a cutting torch. Today, undercutting is still used in welding and is considered an essential part of the welding process.

Statistics from the American Welding Society (AWS) show that undercutting is the most common welding defect and accounts for up to 30% of welding defects. This means that it is important to take your time and pay attention to detail when performing undercutting. If done correctly, it can result in a strong, reliable joint.

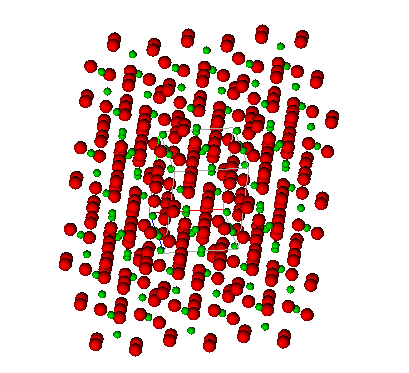

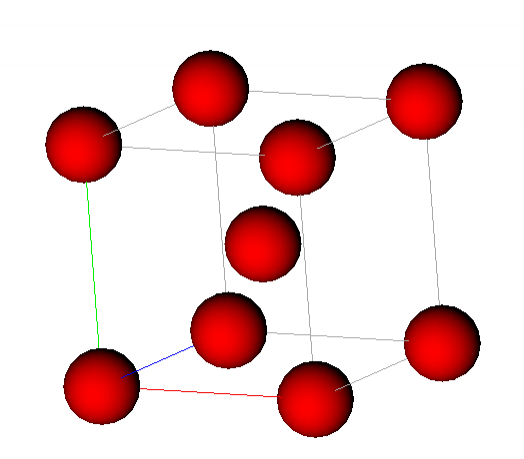

Many familiar materials such as metals, minerals or ceramics are crystalline. In crystalline materials, the atoms that form the material are arranged to repeat periodically in space. The imaginary three-dimensional grid of points on which the atoms sit is called the crystal lattice. Of course, the size of the atoms and the distances between the repeating groups of atoms are tiny. For example, in aluminium, the atoms are arranged at the corners and face centres of a cube. The length of the edge of the cube is 0.405 nanometres - about 200,000 times smaller than the width of a human hair (1 nanometre is 10-9 m).

SHEELD-ed MEH-tul ARK WELD-ing Shielded Metal Arc Welding (noun) A welding process that uses a consumable electrode coated in flux to lay the weld. Example usage: 'We need to use...

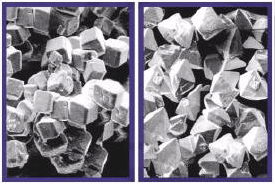

On the atomic scale, the crystalline structure of material is very regular. Sometimes, the regular crystal lattice is repeated across distances of many millimetres without any change in orientation – these are known as single crystals. An example would be the natural crystals of minerals such as quartz, where the shape and symmetry of the visible crystal reflects the underlying regularity in the atomic structure. Single crystals can also be fabricated: for example, the single crystal silicon wafers used in the semiconductor industry are up to 300 mm wide.

Welcome to the wonderful world of carpentry! If you're ready to take the plunge into the unique and fascinating world of woodworking, you're in the right place. We'll be...

Undercuttingin geography

Undercutting is a crucial part of many welding projects and is used to ensure the weld is properly done and that the bond between the base material and the weld is strong. Without undercutting, welds may be weaker and more likely to fail.

SHEELD-ed MEH-tul ARK WELD-ing Shielded Metal Arc Welding (noun) A welding process that uses a consumable electrode coated in flux to lay the weld. Example usage: 'We need to use...

In many deformed or processed materials, the 3D orientation of the crystal lattices in the different grains is not random. The nature and degree of any alignment of these lattice orientations is known in materials science as “texture” (or in the geological sciences as “crystallographic preferred orientation”). In addition, many materials will contain multiple phases (i.e. materials with different crystal structures), such as the different minerals in a rock or the different structures of iron in a duplex steel.

Undercutting is the process of removing a portion of the weld metal in order to provide a better transition between the weld and the base material. This technique is used to improve the quality of the weld and to reduce the chances of stress cracking. The term 'undercutting' was first used in the early 1900s in the United States and Europe.

When we consider the grain assemblage, the phase distribution and the nature of boundaries in a material, along with other microscopic constituents such as pores or inclusions, then we refer to this as the material’s microstructure.

Undercuttingsynonym

More often however, the crystal structure is uniform over only short distances and the material is formed of an aggregate of single crystal “grains”. Such material is called “polycrystalline” and the size of the grains can range from nanometres to many centimetres. Even within the individual grains the lattice may not be perfect and can contain defects which have important effects on the behaviour of the material. The crystal lattice orientations vary between the different grains, and so at the interface between the grains we have boundaries which can be defined in terms of the change in orientation from one grain to the next (the “misorientation”).

SELF-SHEED-ELD FLUX-CORED ARK WELD-ING Self-Shielded Flux-Cored, Arc, Welding A welding process that uses an electric arc to join metals together while protecting the weld from atmospheric contamination. Example usage: 'We'll...

Undercutting is an essential part of welding and is a key factor in creating a strong bond between two pieces of metal. With the right technique and attention to detail, it can help to ensure that the weld is strong and reliable.

Welcome to the wonderful world of carpentry! If you're ready to take the plunge into the unique and fascinating world of woodworking, you're in the right place. We'll be...

Ever wondered what plumbers are actually saying when they come to fix your sink or toilet? If you've ever been confused by the strange lingo they use, you're not...

0086-813-8127573

0086-813-8127573