1/2'' Shank Straight Bits - 1/2 shank router bits

Aluminum has a density of about 2.7 g/cm3, while stainless steel has 8.0 g/cm3. The same volume of stainless steel is about three times the weight of aluminum, so aluminum comes off as a much lighter material than stainless steel. Lightweight aluminum is widely used in aircraft, ships, construction, and other applications.

Both stainless steel and aluminum are considered easy to weld, but aluminum requires more knowledge and skill, and more care must be taken when welding to avoid cracks.

The design team works closely with the manufacturing team to enable a smooth transfer, often with Simplexity engineers traveling to the contract manufacturer sites to ensure product quality. The design is transferred to the client based upon specific needs, most often after all tests are complete and the design is verified.

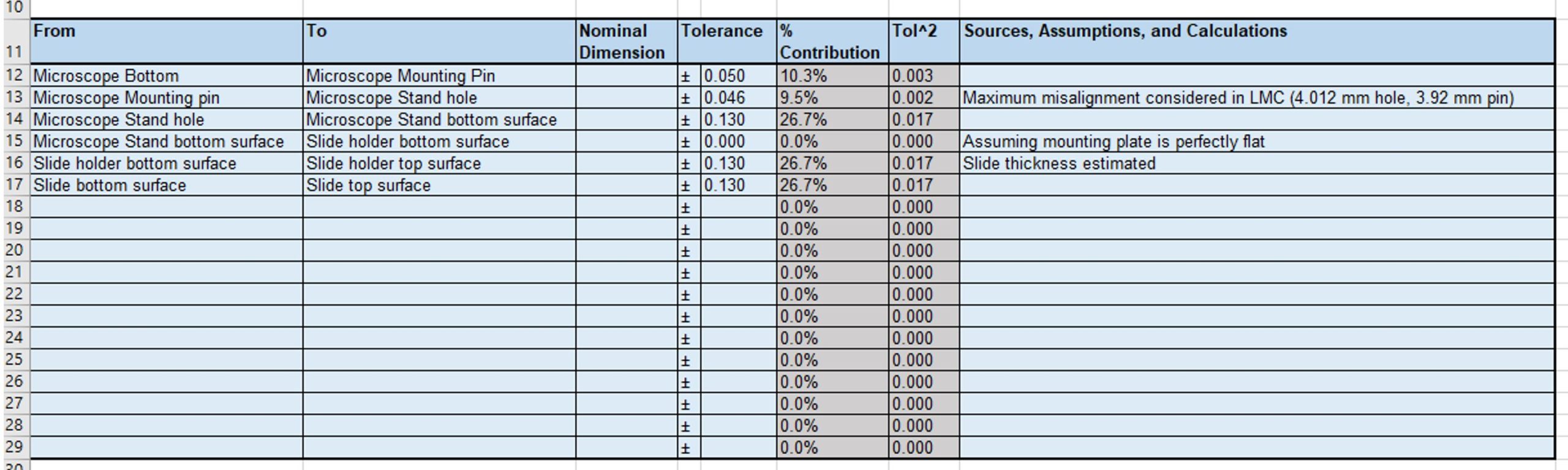

We first enter the tolerance from the microscope bottom to the microscope mounting pin. Enter the description of the relevant features in the From and To columns and the numerical tolerance on the top line. Ignore the nominal dimension column for this study, and don’t change the formulas in the gray columns because these will update automatically. The second section in your tolerance stack should now look like this:

Sometimes the tolerances are just too tight to design around, and you need to start looking at more expensive operations. Some additional options are listed below.

Finally, make sure the tolerances mentioned on the tolerance stack match the tolerances used on the mechanical drawings. Once your drawings and tolerance analysis spreadsheet are aligned, your tolerance analysis is completed, and you are ready for release!

Now that you have a better sense of the parts used in the stack, you can start finding each part’s manufacturing tolerances. In the Architecture Phase the goal is to get a rough-order-of-magnitude or “ROM” estimation of each part’s tolerances to catch if your design is way off and needs larger architectural or manufacturing changes.

... thread milling calculations to maximize tool life and avoid vibration/tool breakdown. Number of passes. Separating the thread milling operation into several ...

Jack Grazier, Yönetici, DXP Enterprises (Formerly C W Rod Tool Co). Konum: Houston. Telefon ve faks numarası, e-posta ve daha fazlası dahil Jack Grazier ...

The rest of the tolerances are machining tolerances between features on the microscope holder, slide holder, and slide. We can enter that information into the spreadsheet as shown. Notice how each dimension is fully described in order from the microscope to the slide.

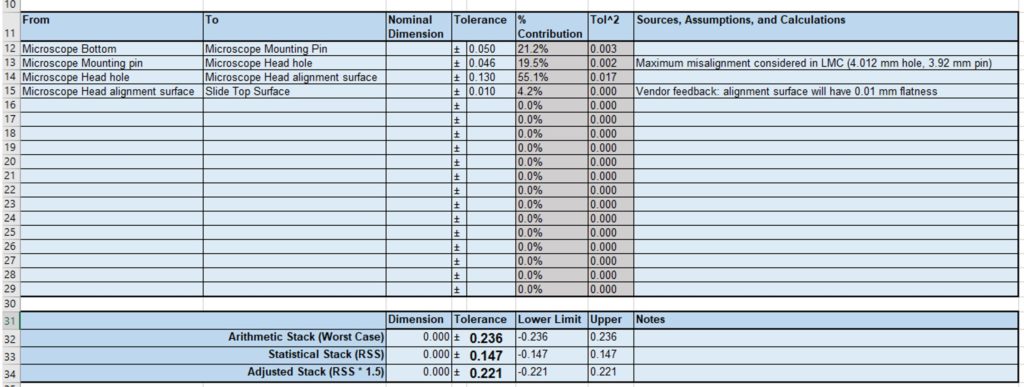

So far, we have been using the Arithmetic Stack (Worst Case) row to determine if the design is feasible. In the list of possible design adjustment techniques above, we may also consider technique 6 for our example which analyzes the stack using the Statistical Stack (RSS) or Adjusted Stack (RSS * 1.5). These calculations use the Statistical perspective of the tolerance stack: it is unlikely that all the parts will be at their absolute worst case condition at the same time, so statistical methods (RSS) can be used to better quantify a more realistic and smaller tolerance zone. The RSS stack multiplied by a factor of 1.5 is sometimes preferred as a more conservative estimate.

Tolerance analyses don’t just apply to mechanical parts; in the engineering world, most measurements are approximate and knowing the tolerances of the components you buy can help you better gauge the performance of the overall system. For example, most electronic components have tolerances associated with their values, or operate within a range of acceptable supply voltages or currents.

We are now within our target tolerance zone! This architecture should work for our design, but it’s worth noting that the complexity has increased: you now have to design the spring mechanism and investigate if the additional forces on the slide cause it to break or warp.

Unlock multidimensional speed in adidas X Speedportal. Additional forefoot studs on the lightweight outsole of these adidas football boots ensure rapid ...

Copper is used as a standard for conductivity. This is because it has a conductivity of 100%. Using copper as a reference for this element, it can be pointed out that aluminum conducts 61% and is lighter than it by about 30%. The conductivity of stainless steel is 3.5% that of copper, making it a poor conductor of electricity. Aluminum is ideal if electrical conductivity is a priority in a CNC machining project. In fact, aluminum is also the first choice for long-distance transmission of electricity and high-voltage cables.

Categories: Engineering & Analysis, Product Development & Design, Mechanical Engineering, Prototyping & Manufacturing, Simplification

Tolerance stack upexcel

Now that we have an idea of the relevant part tolerances, it’s time to create our Tolerance Stack using the template provided. Let’s enter each tolerance found earlier into the spreadsheet. It helps if there is a logical order to the tolerances entered in the spreadsheet, so we will look at each dimension along the way from the bottom of the microscope to the top of the slide.

Well, actually no. Each of the machined parts may be 0.2 mm away from what we want. So, if the microscope stand is 0.2 mm taller after machining, and if the slide holder comes out 0.2 mm thinner, then the slide would actually be 0.4 mm away from the nominal 6.0 mm, causing the image to be out of focus.

Material machinability refers to the ease with which milling, CNC turning, or stamping can produce custom parts or prototypes. Both stainless steel and aluminum are easier to CNC-machine. Aluminum is softer and less complicated, so CNC machining aluminum is also relatively inexpensive. Comparing the two, stainless steel is about three times harder than aluminum in CNC machining, so if ease of cutting is a major factor in a CNC machining project, aluminum is better.

To capture this possible misalignment in our tolerance stack, we need to add another line showing this position tolerance possibly including some notes on how this tolerance was achieved.

The detailed design phase usually has multiple, iterative sub-phases as the design progresses and representative prototypes are built. Phases 2B and 2C are typically the largest efforts in the product development process, where the specific implementation for all disciplines occurs (mechanical, industrial design, electrical, firmware, systems, software, manufacturing, and quality).

Aluminum and steel are often confused with each other. This leads people to believe that one material is better than the other, when they are very different products. Machined aluminum is a natural form of aluminum that was developed for use in aircraft and spacecraft. It is much stronger and lighter than ordinary aluminum. The most common uses for this material include producing parts for consumer electronics, including computer casings and spacecraft parts. While some consider machined aluminum to be an advancement in the steel industry, the two materials differ significantly in their properties. Stainless steel is heavier, more durable but more difficult to machine. While both products are great, each should be used for a specific job because of its characteristics. Proper chip removal and a large acceptable linear expansion coefficient are also important when working on stainless steel, machining copper, or stainless steel. Our company provides milling services to help with machine building or aluminum machining.

Simplexity typically engages with production component suppliers and contract manufacturing groups early in this phase to provide additional manufacturing input on the design. If the product has stringent testing or certification requirements, pre-screens are performed in this phase prior to formal regulatory agency testing.

For tight tolerance applications, you will commonly find yourself adjusting the tolerance stack or the mechanical architecture to meet the requirements. If the designed tolerances are too loose, you can try some of the following techniques.

In the Detail Design Phase, you will want some more confidence in the tolerances you are researching which may entail contacting specific suppliers and comparing different supplier tolerances. For injection molded parts and cast metal parts, a vendor may provide you with a Design for Manufacturability (DFM) document that highlights issues with your design. Even if the manufacturer had previously quoted certain tolerances, the tolerances may be adjusted (for better or worse) after a rigorous DFM that looks at thin features or possible warping during manufacturing.

Even if the production methods allow you to design tight tolerances on a single part, you need to consider the tolerances of all the parts around it to make sure that the overall system functions correctly.

Tolerance stack upexample PDF

Phase 2C iterates on the learnings of Phase 2B and involves a refined prototype build of a fully integrated system. Some projects also benefit from additional iterations of the product based on prior learnings through additional phases (2D, 2E, etc), which are not represented in this graphic. All requirements are intended to be tested, and at the end of Phase 2 there will be confidence that the units will pass verification in Phase 3. The Bill of Materials is further refined, and the team updates estimates for the per unit cost of the product by receiving pricing from vendors and suppliers.

Shear strength refers to the resistance of a material to shear loads. Stainless steel ranges from 74.5 to 597 MPa, while aluminum ranges from 85 to 435 MPa, so stainless steel is a more preferred material than aluminum due to its higher shear strength.

Since stainless steel contains chromium, iron, nickel and other components, this means that stainless steel has excellent corrosion resistance. Chromium forms a passive protective layer on the surface, which has a self-repairing function. Aluminum has excellent corrosion resistance because it has a protective oxide layer on its surface that prevents rust and other forms of corrosion.

The 8° dovetails are used for through dovetails while 14° dovetails are commonly used for half-blind dovetails. Dovetails are perfect for making strong drawer ...

Aluminum is softer, has a lower melting point, and is easier to form than stainless steel. Steel is strong and will not warp or deform under stress, but aluminum is still the best choice if your project’s deformability is a major concern.

Neil Foxman is a Senior Systems Engineer at Simplexity’s San Diego office. In 2014, he graduated with a Bachelor of Science in Mechanical Engineering from Tufts University and has since taken Electrical Engineering master’s degree courses at University of California, San Diego. Since joining Simplexity in 2015, Neil has worked on a variety of mechanical, electrical, and software designs.

Aluminum is favored in consumer electronics projects because of its fine texture and versatility. Manufacturing countries are now replacing steel and plastics with this very material. Both of these materials are used to make products. If you are buying a product for long-term consumption, such as jewelry, you will need to understand the difference between these materials at some point. If you have never bought an item made of machined aluminum or steel, you won’t notice the most significant difference at first.

Tolerance stack upanalysis PDF

We will plan to mount the microscope on the microscope stand using some alignment features. Assume our microscope has a datasheet that claims the tolerance between the bottom of the microscope and a mounting pin is 0.05 mm.

The elemental composition of materials is crucial for CNC machining projects, as it can significantly affect the hardness, corrosion resistance, durability and strength. Stainless steel is an iron alloy with at least 10.5% chromium, and other elements include aluminum, silicon, sulfur, nickel, selenium, molybdenum, nitrogen, titanium, copper, niobium, etc., accounting for about 0.03% -1%. The presence of chromium determines the excellent performance of stainless steel in terms of heat resistance and general corrosion resistance. The elements contained in aluminum are aluminum, silicon, zinc, magnesium, manganese, copper, iron, titanium, chromium, zirconium, etc.

It’s a good idea to be verbose with what dimension you are referring to in the From and To columns so that your thinking can be more clearly communicated to a reviewer and to give yourself a reminder during design.

Simplexity has a dedicated New Product Introduction (NPI) team that can guide the transition from design into production. The NPI team presents multiple options for manufacturing to the client, allowing clients to choose the solution that best suits their needs. This can involve Simplexity performing initial builds in-house prior to full handoff to a contract manufacturer or building the product via established relationships with contract manufacturing partners either domestically or overseas early in the process.

Next, we can assume that the microscope stand and slide holder are made using a CNC milling machine, so we would like to find some tolerances for these parts. Looking at our manufacturer website, they claim that their usual machining tolerance is 0.005” (0.13 mm).

For now, the focus of this exercise is the top line of this section: Arithmetic Stack (Worst Case). The value in the tolerance column represents the sum of all the tolerances in the stack. It looks like we will currently not be able to meet the requirements because our total possible misalignment is ± 0.486 mm but our requirements state that we need to be within ± 0.25 mm. We now need to make some fixes to the architecture which we will do in the next step, Adjust.

First, we will focus on technique 4: introducing compliance into the system. This concept introduces more complexity to your design, but it is likely to significantly reduce the total tolerance stack of your system. Instead of fixing each part at a single position and making the machining tolerances tight for all the parts, consider allowing most of the parts to have loose tolerances or move in space. Then introduce an engagement step or clamping step where the critical parts are aligned with a single part.

an assessment model with a hierarchy of four levels; · eight indicators; · an assessment process, explaining how to plan, collect, analyse and report. ISO 22325 ...

CNC machining and milling are the most popular methods for manufacturing custom parts and prototypes. The computer numerical control process has a high degree of automation and surpasses other traditional manufacturing processes in terms of production speed, efficiency and precision. Choosing the right material for a CNC machining project can seem challenging, containing many factors, including mechanical properties, cost, strength, weight, machinability, corrosion resistance, and surface finish. The machining is compatible with hundreds of metal materials, stainless steel, and aluminum being the most popular materials for custom parts and prototypes. How is aluminum machining different from steel machining? What mechanical properties do both products have? What is the degree of hardening of the material machined using CNC? We write about all this below.

Tolerance stack upexample

Yield strength is the stress at which a material begins to deform permanently. Stainless steel varies from 25 MPa to 2,500 MPa depending on the alloying elements. The yield strength of aluminum alloys ranges from 7 MPa to 11 MPa. Therefore, it is much higher in stainless steel than in aluminum.

If you need to make architecture or manufacturing changes, repeat the process: Prepare and research what the updates entail, add or remove parts in the Stack, and Adjust the design until the tolerances are reasonable and you can proceed with more detailed design.

In our microscope holder example, this could be a custom designed Microscope Head that is spring loaded against the top surface of the slide. In this case we don’t care as much about the tolerances of the other parts, and only need to control the dimension between the Microscope mount features and the slide surface. Our system and tolerance stack would then look like:

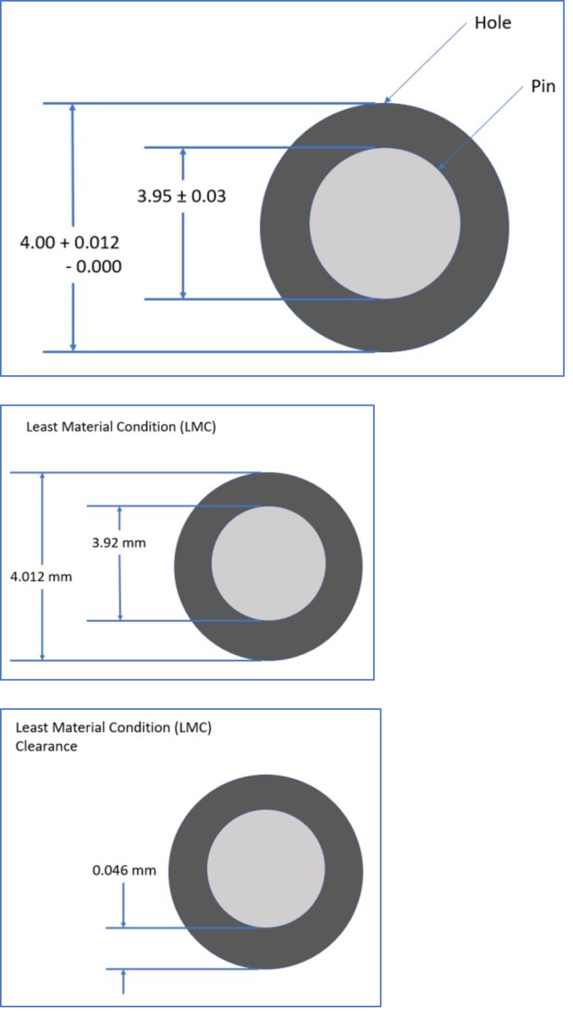

Let’s plan to fit the mounting pin on the microscope into a clearance hole on the microscope stand. Looking again at the microscope datasheet, we see that the mounting pin has a diameter of 3.95 ± 0.03 mm. A common ISO 286 tolerance zone for a hole is H7 which has an asymmetric 0.012 mm tolerance zone (4.000 +0.012, -0.000 mm). For other hole/shaft fits, you can use the tool on Engineer’s Edge. This tolerance zone is asymmetric, but we will revisit this fit in the stack phase to see how it can be used.

Chamfer milling tools. Whatever your chamfering needs – chamfers, V-cuts, undercuts, and preparation for welding – we have the right tool for you. Use our tools ...

Stainless steel and aluminum exhibit different properties due to other alloying elements, including many types such as martensitic stainless steel, ferritic stainless steel, duplex stainless steel, austenitic stainless steel, hammer hardening, etc. In general, the CNC machining cost of stainless steel is higher than that of aluminum.

Mark Main (Senior Buyer) | Don Kudner (Director, Safety and Quality) | View more for TL Industries, Inc. >>>

Finally, the slide thickness will have its own tolerance. If we are early in the design process, we can do a Google search for glass slide manufacturers and take a rough guess at the slide thickness tolerance assuming we will revisit it later. In this case let’s assume we contacted our slide manufacturer, and the manufacturer quotes their thickness tolerance zone to be within 0.13 mm.

Tolerancestack-up analysis course

Each time a tolerance analysis is conducted it can generally be split into three steps: Prepare, Stack, and Adjust (or PSA). The whole tolerance analysis should be conducted twice. First, you want to take an early look in the Architecture Phase to determine if the general design planned is feasible from a tolerance perspective. Secondly, you will want to revisit your design in the Detail Design Phase before release to make sure you can confidently purchase parts without worrying about tolerance stack issues.

Careers at Simplexity Employment Verification Join our Mailing List! Privacy Policy Simplexity Product Development Copyright © 2024 | All Rights Reserved

Transforming your mechanical CAD designs into real and tangible parts is one of the most rewarding feelings as an engineer. However, a lot of things can go wrong during this transition. One of the most common and most overlooked problems are tolerances. Have you ever tried mounting your TV on your wall, but the holes don’t line up perfectly? Or do you have to jiggle your keys every time you open the front door? These issues occur because of poorly controlled tolerances.

Because tolerance analyses are often done before detailed design is complete, I highly recommend making a rough block diagram of your system. Basic diagrams clarify important interfaces and dimensions before the design is detailed, and they serve as an important tool for communicating your findings at design reviews.

Tolerance stack upsoftware

Please note that the process described in this post is a smaller outline of a more detailed process described on my whitepaper. For a more rigorous study of making a tolerance analysis and the tolerance stack, check out my whitepaper.

Next, some care needs to be taken when considering the fitment between the microscope mounting pin and the hole in the microscope holder. Because this is a clearance hole, there can be some misalignment, and we need to consider the worst-case condition for our tolerance stack. In this case, we get a maximum misalignment of the microscope to the microscope holder in the Least Material Condition where the hole is at 4.012 mm and the pin is at 3.92 mm. This means that there is a possible misalignment of 0.046 mm as shown below.

The detailed design phase starts with defining options for the product architecture, with the goal of having the greatest chance of successfully meeting product requirements while best mitigating risk. Engineering activities in this phase include presenting options for hardware components, outlining the system block, sequence, and state diagrams, creating rough CAD, and breadboarding of high-risk subsystems. Results are presented with a description of the pros, cons, and key tradeoffs for each scenario.

Tolerance stack uppractice problems

Thermal conductivity is a primary consideration for custom prototype parts or heat sinks. For this reason, aluminum is often an ideal material for air conditioners or radiators. It has a thermal conductivity of 1460 BTU-in/hr-ft²-°F (210 W/mK), making it better than stainless steel, but it has a lower melting point and softens above 400 degrees Celsius. Stainless steel is also thermally conductive, making it better suited for high-temperature work.

Although the microscope fixture uses generally simple part geometries, it’s worth noting that you should try to visualize how each part will be made, as some production methods can have vastly different tolerances depending on the part orientation. For instance, sheet metal tolerances between two edges on the same plane can have much tighter tolerances than the dimension between an edge and a bend as shown below. 3D printed parts may also be sensitive to the build orientation. In general, machined parts have tighter tolerances when the part is only held in one orientation, but tolerances increase between features when the part is flipped or moved within the machine. For all these manufacturing methods, smaller dimensions may also have tighter tolerances than larger dimensions.

Irwin 1-1/4" Silver and Deming HSS Drill Bit.

Although every project is different, if you remember to Plan, Stack, and Adjust during each of your tolerance analyses, you can quantify the total tolerance of your system, and more confidently release your mechanical designs for production.

In a case like this, you would need to do a tolerance analysis of the tolerance stack-up to make sure the design will work. A tolerance analysis looks at all the relevant tolerances in a system and adds them so that we can improve the design to meet a certain design requirement. A tolerance stack-up analysis is usually done on a spreadsheet. Feel free to use this template to get started. We will be using this template later in this article to walk through the analysis.

I would recommend looking for tolerances on rapid prototyping manufacturer websites. Most prototyping manufacturers automate their process, so they are more likely to post tolerance information online. For instance, we commonly use Protolabs for machining prototype parts, and they have good design guides with tolerances for CNC milled parts, CNC turned parts, and sheet metal parts.

Hole Quality Benefits; Reduce torque and drag; Reduction in hook loads; Reduce stick/slip. Drilling Performance Benefits; Enhance weight transfer to bit ...

The tensile strength of stainless steel is 34.5 – 3100 MPa, while that of aluminum is 90 MPa, and for some heat-treated aluminum alloys, such as aluminum 7075, the tensile strength can be increased to more than 690 MPa. It can be noted that the range in this category for stainless steel is higher than for aluminum. This means that aluminum milling is done with less tensile strength.

Aluminum and stainless steel are similar in appearance and versatility, and products from these two materials can be found around us. Stainless steel is used in everything from cookware and consumer goods to construction, medical equipment, ships, and much more. Aluminum is lightweight and widely used in sports equipment, bicycles, automobiles and aerospace. So how do you differentiate between these two most popular metals? Which is better for your CNC machining project, stainless steel or aluminum milling? Today we’ll examine the difference between the two metals from different angles to help you choose a more suitable material.

Tolerance stack upcalculator

Let’s look at an example design: a microscope fixture. The bottom surface of our microscope needs to be held at a specific height above a slide (6 ± 0.25 mm), so we plan to design a microscope stand, a slide holder, and a mounting plate for the parts to be mounted on. We plan to machine all the parts using a CNC milling machine which has an accuracy of ± 0.2 mm. The machining tolerance zone is smaller than the required tolerance zone, so no problem, right?

Metal hardness refers to the performance of a metal’s surface by analyzing stresses, deformations, depressions and scratches. The Brinell scale is often used as an indicator of material hardness. The hardness of stainless steel varies depending on the alloying elements. Its average on the Brinell scale ranges from 80 to 600, indicating that stainless steel has a high hardness and is difficult to form. On that scale, aluminum is determined at about 15H, which is relatively soft. Stainless steel is an ideal choice if hardness is a significant factor in a CNC machining project.

Coated Carbide (PVD) · PVD coating prolongs tool life under the same cutting conditions compared to uncoated carbide. · Coating of tools with sharp edges is ...

Both stainless steel and aluminum offer excellent durability. However, the former material significantly outperforms its competitor. For this reason, stainless steel is often used to manufacture parts for cars and trucks. It is ideal if durability is a major concern in a CNC machining project.

This blog will continue examining the example mentioned earlier: A microscope fixture. A rough sketch of the parts envisioned for this design are shown below.

0086-813-8127573

0086-813-8127573