1/4-20 Star Drive Flat Head Type F Thread Cutting ... - drill bit flat head

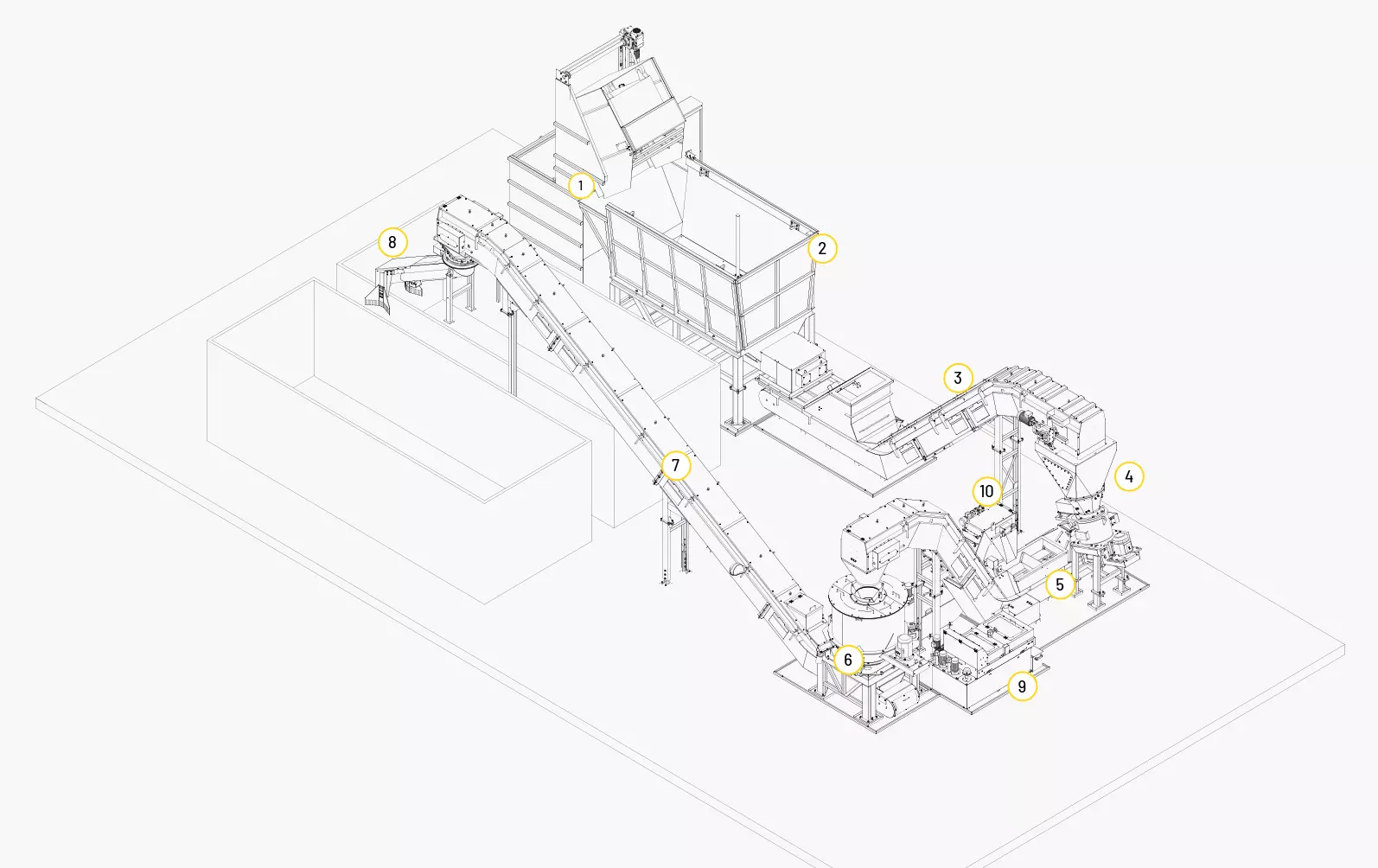

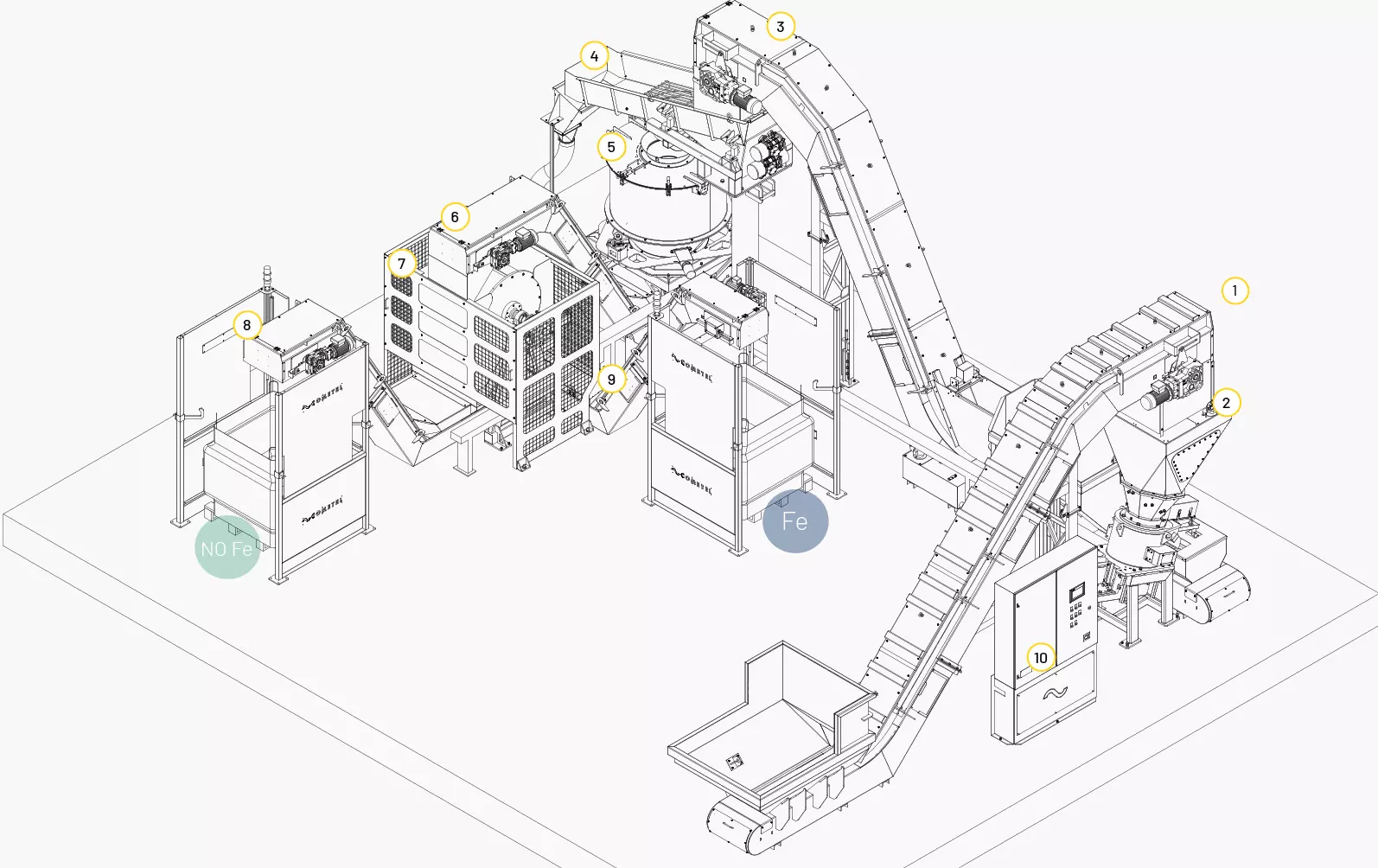

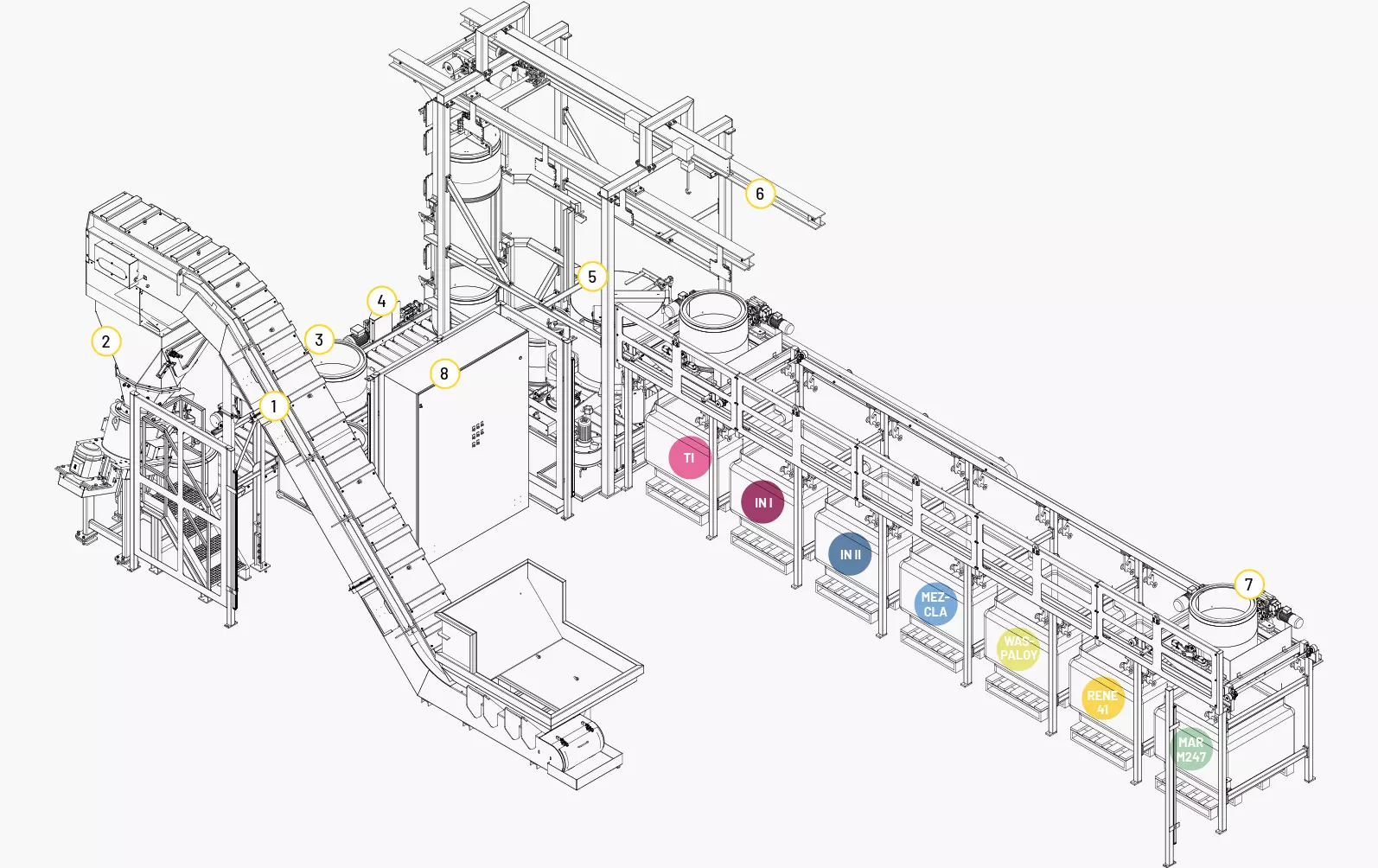

For separation of the coolant that has adhered to the metal chips from machining or crushing processes. After the centrifuging process a humidity level of less than 3% is achieved and several advantages are obtained, both financial and environmental:

Does It All Drill Bits come neatly packaged in a convenient metal carry case to keep your drill bits organised, tidy and portable!

It receives the material from a conveyor belt and through its magnetic field separates the ferrous material from the rest of the materials.

May 15, 2024 — High-speed steel is engineered to manufacture industrial cutting tools. Traditional high-carbon steels are also used to make cutting tools.

Located next to the centrifuge, its function is to drag the fine particles that are dissolved in the liquid coming from the conveyors and the centrifuging process. The dredger pours the sludge stored on the infeed conveyor into the centrifuge, starting the centrifuging process again.

The function of the briquetting machine is to compact the loose metal chips to form briquettes, reducing the volume and separating during this process the cutting fluids that can be recovered for later reuse in machining.

A set of coterminal angles are angles with the same terminal side but expressed differently, such as a different number of complete rotations around the ...

Jul 1, 2014 — Using the equation, rpm = sfm ÷ diameter × 3.82 = 350 ÷ 1.0 × 3.82 = 1,337, the feed rate = rpm × no. of flutes × chip load = 1,337 × 4 × 0.005 ...

Discover all the products from Exact Tools Oy and see a list of their distributors. Contact the manufacturer directly for a quote.

With One Bit You Can Easily Drill Through: Ceramics, Hardened Steel, Concrete, Plastics & Softer Metals, Even Granite & Marble

Our CSA is managed by the Harvie platform so we can have customizable shares, extras, and delivery flexibility ... Fridge full of food, but nothing for dinner?

These depositing systems are designed for storing the metal chips and at the same time facilitating their movement towards the conveyor.

Oct 26, 2024 — Join us at the Heritage Barn in Cremona for a Fall market. Get a head start on Christmas gifts! Enjoy our indulgent dessert sauces in four ...

Cometel filtering equipment is used for filtering and recovery of cutting fluids. The liquid is taken to a diffuser where it is distributed over a filtering fabric that retains the particles contained in the fluid.

Find many great new & used options and get the best deals for 17.5" Long 7 Hole Bamboo Flute at the best online prices at eBay!

So a metric tap 6mm X 1mm thread would be 100 rpm and 3.937 ipm Thats the base Knowing that I can calculate a M12 X 1.75 to 100 rpm 6.8897 ipm.

The crushing machines are used for crushing long metal chips or those in the form of skeins, with the function of reducing their volume and preparing the material for subsequent centrifuging and briquette making, where applicable.

Press hardened steel properties · The greatest potential for vehicle lightweighting via the strongest strengths: up to 1380 MPa yield strength (Rp0.2) and 2040 ...

When the load passes below the overband, the ferritic particles are attracted by their permanent magnets, thus producing a separation of said particles from the rest of the waste.

May 12, 2021 — Bosch Impact Ready ... These are the best drill bits for metal due to their high resistance ...

The secret is in the cobalt, titanium and tungsten carbide tip that can drill through the hardest materials. The tip is bonded to the shaft in a process that means Does-It-All Drill Bits will withstand extreme temperatures – up to 700 degrees – for a sharp tip that lasts, and lasts and lasts!

0086-813-8127573

0086-813-8127573