15332 Sales Tax Calculator: Lookup Pennsylvania Tax Rates - 15332 zip code

Customs delays in some cases can add a couple weeks of delays in some cases depending on time of year. For example during the holiday rush wait times can be longer for customs clearance so order early.

Titanium multi toolreview

Industry leading 365 Day Warranty! Just reach out and we will send you a label or directions to make the process quick & easy!

In order to eliminate this time loss, we can, and should, use recommended metal-removal rates that have been researched and tested by steel and cutting-tool manufactures. We can find these cutting speeds and metal removal rates in our appendix or in the Machinery’s Handbook.

Full 365 day warranty on all items we sell from defect or failure. We stand behind every product we sell 100% from watches to flashlights, we have you covered!

6. As the softness of the material decreases, the cutting speed increases. Additionally, as the cutting tool material becomes stronger, the cutting speed increases.

All products are returnable. Within 10 days of receipt of your shipment. In original condition / brand new. In the original packaging

Our online shopping cart provides a safe and convenient online purchasing system for a credit card or PayPal orders through Shopify. You do not need a PayPal account to order from CountyComm. If you prefer to order off-line, you can place an order through the mail. If you sent an email and didn't get a reply then we didn't get it or it went into the spam bucket. Check your email for notification of tracking number titled "Quantum view ".

Once your return is received and inspected, we will send you an email to notify you that we have received your returned item. We will also notify you of the approval or rejection of your refund.

Besttitanium multi tool

Meet the Little Jimmy Titanium Multi-Pry Tool by Maratac®—the ultimate EDC tool that packs maximum utility into a compact, stylish design. Built from ultra-durable Grade 5 titanium, this tool is lightweight yet virtually indestructible, making it a perfect addition to your keychain, whether you’re at a formal event or in the great outdoors. With a unique blend of rugged functionality and refined design, the Little Jimmy is your go-to tool for all situations.

With its combination of functionality, durability, and style, the Little Jimmy Titanium Multi-Pry Tool by Maratac® is the only tool you’ll ever need on your keychain.

ONLINE: CountyComm accepts payment by Visa, MasterCard, American Express, Discover and PayPal through our website that is secure and managed by Shopify.

Bigger & beefier than the small pry bars, more compact than the breacher bars, this Glow PryX Mini Titanium Multi - Tool falls right in the middle. Nice honeycomb finish, pry section, nail puller, bottle opener and, of course, this uber nice glow. Being made of titanium, there's always the possibility to create some nice colors for some extra bling. I'd like to see a clip in a future version to come...

Double Check Your Address: Please be sure to double check your order when you are asked to "Review Your Payment". We will ship your order to the address shown. Once your order is in our shipping department it is almost impossible to change your address.

Titanium multi toolamazon

Example: Material = Aluminum 3” Cutter, 5 Teeth Chip Load = 0.018 per tooth RPM = 3000 IPS = 0.018 × 5 × 3000 = 270 Inches Per Minute

If you were cutting thread all day long: day in and day out. You might set the lathe up for only two cuts. One cut to remove all but .002 or .003 of material and the last cut to hold size and finish. This is done all the time in some shops today.

Titanium multi toolfor sale

4. What would the RPM be if we were turning a 1.00” diameter workpiece made out of mild steel, using Carbide cutting tool?

Note: please insure the item accordingly. In any case, a return authorization number must be obtained before returning any items to us. The return authorization number must be clearly printed immediately beneath the "ship to" address.

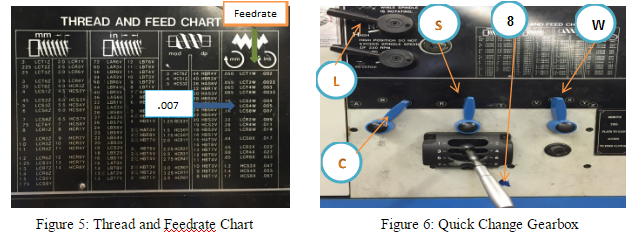

7.W = Select Feed Ranges and change to W on this lever (See Figure 3) Before turning on the lathe, be sure all levers are fully engaged by turning the headstock spindle by hand, and see that the feed rod turns.

Titanium multi toolprice

CountyComm is not responsible for COD / Duty Fees for incoming packages domestic or abroad.To prevent fees please don't insure incoming packages for full value.

5. Roughing cuts (0.01 in. to 0.03 in. depth of cut) for most aluminum alloys run at a feedrate of .005 inches per minute (IPM) to 0.02 IPM while finishing cuts (0.002 in. to 0.012 in. depth of cut) run at 0.002 IPM to 0.004 IPM.

To operate any machine efficiently, the machinist must learn the importance of cutting speeds and feeds. A lot of time can be lost if the machines are not set at the proper speed and feeds for the workpiece.

If you are approved, then your refund will be processed, and a credit will automatically be applied original method of payment, within 10 business days.

The feed of on lathe, or the distance the carriage will travel in on revolution of the spindle, depends on the speed of the feed rod or lead screw. This is controlled by the change gears in the quick-change gearbox. This quick change gearbox obtains its drive from the head stock spindle through the end gear train. A feeds and thread chart mounted on the front of the quick-change gearbox indicates the various feeds and metric pitches or thread per inch which may be obtained by setting levers to the positions indicated.

We want you to be excited and happy with everything you buy from CountyComm so we offer quick & easy returns so you never have to worry ( Click Here )

Have you noticed that when you take a very small cut on the lathe .001 to .002 that the finish is usually poor, and that on the rough cut you made prior to this very light cut, the finish was good? The reason for this is: some tool pressure is desirable when making finish cuts.

Titanium Multi ToolBlades

Sales Tax: As a California corporation, we are required to charge state and local sales tax on orders shipped to California and some other states based on volume.

The recommended feeds for cutting various materials when using a high speed steel cutting tools listed in table below. For general purpose machining a .005 – .020 inch feed for roughing and a .012 to .004 inch feed for finishing is recommended.

Manufacturing Processes 4-5 Copyright © by LamNgeun Virasak is licensed under a Creative Commons Attribution 4.0 International License, except where otherwise noted.

4. Feed rate and cutting speed are mostly determined by the material that’s being cut. In addition, the deepness of the cut, size and condition of the lathe, and rigidity of the lathe should still be considered.

For general purpose machining, use a recommended feed rate of .005 – .020 inches per revolution for roughing and a .002 – .004 inches per revolution for finishing.

Whenever possible, only two cut should be taken to bring a diameter cut. Since the purpose of a rough cut is to remove excess material quickly and surface finish is not too important. A coarse feed should be used. The finishing cut is used to bring the diameter to size and produce a good surface finish and therefore a fine feed should be used.

Titanium multi toolbike

It has been my experience to take at least three cuts. One to remove excess material quickly: the rough cut, one cut to establish finish and to allow for tool pressure, and one to finish the cut.

The lathes are designed to operate at various spindle speeds for machining of different materials. There speeds are measured in RPM (revolutions per minute) and are changed by the cone pulleys or gear levels. One a belt-driven lathe, various speeds are obtained by changing the flat belt and the back gear drive. One the geared-head lathe speeds are changed by moving the speed levers into proper positions according to the RPM chart fastened to the lathe machine (mostly on headstock). While shifting the lever positions, place one hand on the faceplate or chuck, and form the face plate slowly by hand. This will enable the levers for engage the gear teeth without clashing. Never change speeds when the lathe is running on lathers equipped with variable speed drivers, the speed is changed by turning a dial of handle while he machine is running.

Satisfaction on every purchase is very important to us. You can return the item within ten days for a refund. All non-defective returns, items must be in re-saleable condition. No exceptions. For all returns, please first contact us by email mike@countycomm.com for a RMA number. No return will be processed without a valid RMA number. Please include a copy of your receipt or packing list with your phone number with your returned items. All returns must be sent within 5 days after the RMA number is issued. Please pack the item in its original box with all the accessories and ship your item prepaid.

We can control the feed on an engine lathe by using the change gears in the quick-change gearbox. Our textbook recommends whenever possible, only two cuts should be taken to bring a diameter to size: a roughing cut and a finishing cut.

Taxes: New sales tax laws are taking effect starting in 2019 noted by the U.S. Supreme Court case South Dakota v. Wayfair. Many states will be requiring us to charge sales tax.

Titanium Multi Toolpliers

Industry leading 365 Day Warranty! Just reach out and we will send you a label or directions to make the process quick & easy!

There's a good reason they call this metal....God's own metal. Fits in the EDC pouch or on the key ring. Beer even tastes better when you open a brew with it. (except Bud Light). Well worth the money.

International Orders: Currently, we ship International to all parts of the world. if you don't see your region available at checkout let us know and we will add it. We require no minimum order before shipping to Canada / International

A lathe work cutting speed may be defined as the rate at which a point on the work circumference travels past the cutting tool. Cutting speed is always expressed in meters per minute (m/min) or in feet per minute (ft/min.) industry demands that machining operations be performed as quickly as possible; therefore current cutting speeds must be used for the type of material being cut. If a cutting speed is too high, the cutting tool edge breaks down rapidly, resulting in time lost recondition the tool. With too slow a cutting speed, time will be lost for the machining operation, resulting in low production rates. Based on research and testing by steel and cutting tool manufacturers, see lathe cutting speed table below. The cutting speeds for high speed steel listed below are recommended for efficient metal removal rates. These speeds may be varied slightly to shift factors such as the condition of the machine, the type of work material and sand or hard spots in the metal. The RPM at which the lathe should be set for cutting metals is as follows:

Customs delays in some cases can add a couple weeks of delays in some cases depending on time of year. For example during the holiday rush wait times can be longer for customs clearance so order early.

Small Enough for Everyday Carry, Tough Enough for Any Job Meet the Little Jimmy Titanium Multi-Pry Tool by Maratac®—the ultimate EDC tool that packs maximum utility into a compact, stylish design. Built from ultra-durable Grade 5 titanium, this tool is...

The feed of a lathe is the distance the cutting tool advances along the length of the work for every revolution of the spindle. For example, if the lathe is set for a .020 inch feed, the cutting tool will travel the length of the work .020 inch for every complete turn that work makes. The feed of a lathe is dependent upon the speed of the lead screw or feed rod. The speed is controlled by the change gears in the quick change gearbox.

At CountyComm, we're dedicated to excellence, unwavering quality, and innovative solutions. For over 30 years, we've relentlessly provided top-notch tactical gear designed to outlast your adventures.

0086-813-8127573

0086-813-8127573