18bswx3/8ic ext. rh vardex insert vsx - vardex threading insert grades

If you are interested in learning more about this topic or any of the other services offered by Berkness Company, you can visit the Contact Us page on the company’s website. The page provides a variety of ways to get in touch with the company, including phone, email, and an online contact form. The team at Berkness Company is always happy to answer any questions you may have and to provide you with more information about their products and services.

The manufacturing process for making a flute can vary depending on the type of flute being made and the materials used. Generally, the process involves cutting and shaping the material into the desired shape, drilling holes for the finger placement, and adding keys and other components as needed. The final step is often to tune the instrument to ensure it produces the correct notes.

Flutes are typically made from a variety of materials, including metal, wood, and plastic. Metal flutes are often made from silver, nickel, or brass, while wooden flutes are typically made from materials like grenadilla, rosewood, or maple. Plastic flutes are often used for beginner or student instruments.

Experience precision manufacturing with Berkness Company. As a one-stop-shop for CNC Swiss turning and tool and cutter grinding, we pride ourselves on delivering quality products and services that exceed customer expectations. We're committed to providing innovative solutions, fast turnaround times, and competitive pricing. Experience the difference today.

In the production of pipes, flute is used to increase the strength and rigidity of the pipe while reducing its weight. The grooves also provide a better grip for handling and installation. In the manufacturing of musical instruments, flute is used to create the distinctive sound of the instrument. The grooves on the surface of the instrument create a series of air chambers that resonate when the instrument is played. In the production of packaging materials, flute is used to create corrugated cardboard, which is widely used in the shipping and storage of goods.

Warning: Make sure the router bit is properly fastened and tightened in the router’s collet and the bit can rotate freely without any obstructions.

Some common quality issues that can arise during flute manufacturing include uneven tone or pitch, poor intonation, and mechanical problems with the keys or other components. These issues can often be addressed through careful quality control measures, such as testing each instrument before it is shipped to ensure it meets the desired standards.

Berkness Company is a manufacturing company that specializes in the production of custom packaging solutions. The company offers a wide range of services, including flute, to meet the unique needs of its customers. Berkness Company has a team of experienced professionals who work closely with clients to develop packaging solutions that are tailored to their specific requirements. The company uses state-of-the-art machinery and technology to ensure that its products are of the highest quality.

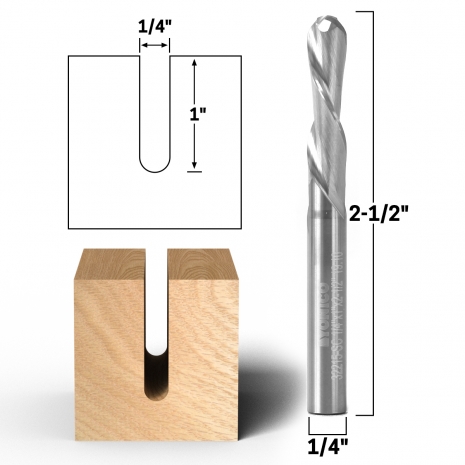

Instructions: Slowly dial up the RPMs on your router to the recommended maximum. Then, dial back if needed to find the “sweet spot”. The sweet spot is the speed at which the least resonant vibration is present. If the sweet spot cannot be achieved within 5,000 RPMs of the max, check the collet for residue or other debris and start over.

Flute is a service performed in the manufacturing industry that involves the creation of grooves or channels on a surface. This process is commonly used in the production of pipes, musical instruments, and packaging materials. Fluting is achieved through the use of specialized machinery that cuts or presses grooves into the surface of the material. The depth and spacing of the grooves can be adjusted to meet the specific requirements of the product being manufactured.

0086-813-8127573

0086-813-8127573