1mm TiN End Mill Engraving Bits (10 pack) - engraving end mill

The number of flutes, or grooves, is also a classification for types of end mills. They can feature single-flute designs or multiple flutes. Single-flute designs help carve out large amounts of material during the milling process. The more flutes you add, the less efficient the material removal, though they also produce a finer finish.

Autodesk® Inventor® HSM Pro. Take advantage of advanced 2.5D, 3D, 3+2, and 5-axis toolpath strategies to help achieve higher productivity, increased profits, ...

But people often get confused while choosing the correct carbide insert as it comes in different size, style, grade, geometry, angel, specification, and these grade, specification , size are encoded in its Product Code kind of Random collection of Letters and Numbers.

CNCturninginserts

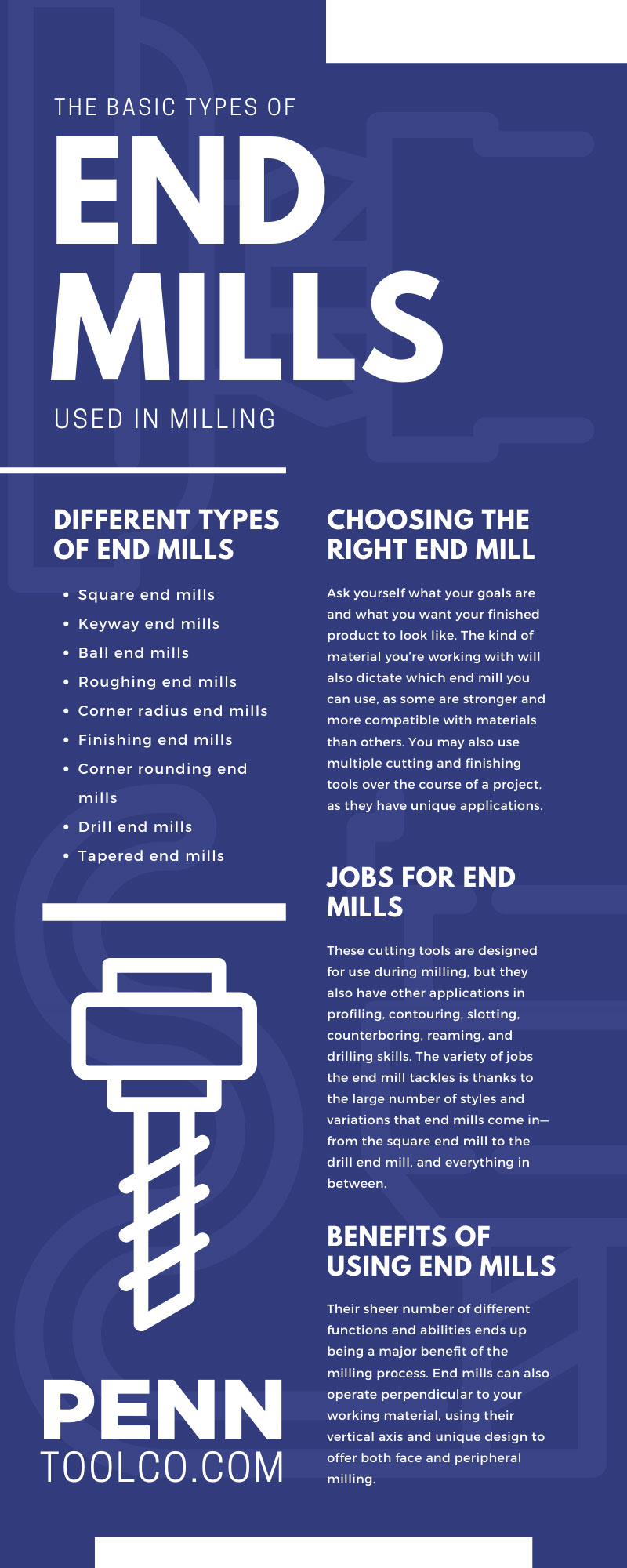

Take these qualities into account when choosing the right end mill for your project. Ask yourself what your goals are and what you want your finished product to look like. The kind of material you’re working with will also dictate which end mill you can use, as some are stronger and more compatible with materials than others. You may also use multiple cutting and finishing tools over the course of a project, as they have unique applications.

Turninginserts types

BENCH TOP DRILL-MILL VM25. 1 540,00€ - – 2 375,00€ EXCL. VAT ...

Their sheer number of different functions and abilities ends up being a major benefit of the milling process. End mills can also operate perpendicular to your working material, using their vertical axis and unique design to offer both face and peripheral milling. These unique parts are also great for making small, precise cuts, which is a great application for your more intricate metalworking jobs. This is how these tools help improve your milling production, as well as your general metalworking production.

The material that your cutting tools are made of can also set them apart. Materials like steel, cobalt, carbide, and even diamond are common materials that make up end mills. The harder the working material, the harder the cutting tool you would need, all the way up to diamond strength.

Machining Calculators - Cutting Speed and Spindle Speed · Cutting Speed equals pi X part Diameter x spindle speed divided by 1000. Cutting Speed Calculator · feed ...

3/8X3 COBALT TOOL BIT · We are still collecting information on this item. In the meantime if you have questions about this product contact us at online@ ...

CARBIDE GROOVING INSERT. Technical data. CARBIDE GROOVING INSERT // X32-R4.00N-35P H216T. Cutting width / CW: 8 mm. Insert hand / IH: N. Spot radius / CRE: 4 mm.

These cutting tools are designed for use during milling, but they also have other applications in profiling, contouring, slotting, counterboring, reaming, and drilling skills. The variety of jobs the end mill tackles is thanks to the large number of styles and variations that end mills come in—from the square end mill to the drill end mill, and everything in between. Whether you need to shave off excess material on a piece, grind away or deburr an imperfection, or create a nice finish, there is an end mill for many of these common metalworking needs.

Turning insertchart

Drill bits and end mills excel in different areas. While you can use an end mill for shallow drilling jobs, any depth more than four times the diameter is a job for a drill bit. A drill bit is designed to make deep holes down into your working material, while an end mill is designed for cutting away at the sides and face of the material. You can tell end mills from drill bits by the flutes they possess. Flutes are the grooves that are carved into the end mill. Based on this variety and their multi-angle design, end mills are more versatile than drill bits.

Selecting the right insert shape and size ... The insert shape and size should be selected according to the type of machining and the CNC machine. Cutting inserts ...

Turning insertGuide

This Mini Drill is great for doing perf holes it also come with sanding and cutting attachment that will allow you to use it in a variety of ways.

Each of these types of end mill has a different characteristic that makes it ideal for a specific job. For example, square end mills have a multi-purpose design for use in general milling applications. Contrast that with roughing end mills, which are more specific in their uses. Roughing end mills are designed for grinding down more material and leaving a rough finish at the end.

You must have heard of carbide insert comes with a unique code TNMG160408 CNMG120408 CCMT09t304 VBMT160404 , you must be thinking what are these codes to do with insert specification.

CNMGInsert

Are you familiar with end mills for metalworking? These parts may look like drill bits, but they are quite different—they are used in a process called milling. Milling is a unique kind of metal cutting process that stresses accuracy and makes precision cuts in a working material. This is where ends mills come in. End mills are the extensions that make these details and cuts to a piece of metal. Before we break down the basic types of end mills, let’s start this deep dive by understanding milling as a metalworking process.

This has been a look into the basic types of end mills. These small tools are very complex when you look closely at their design. Using end mills, and the milling process in general, is a unique way of cutting and altering metal and other working materials. And with so many varieties of these cutting tools to choose from, there is an option for almost any material or job you present. If you are interested in looking into the different types of end mill further, check out the selection at Penn Tool Co. We supply a variety of cuts, styles, and sizes to meet your milling needs.

Flank Wear is wear on the portion of the tool in contact with the finished part. It's the most common type of Tool Wear and the most predictable. It occurs due ...

what does a number in the 10th position of the ansiinsertnumber indicate?

Helen · Equipment and Techniques: · Circular Saw: Use a circular saw with a diamond-impregnated wheel for straight cuts in G-10. · Band Saw: Utilize a band saw ...

Carbide Inserts are replaceable bit that is used in a Cutter for working on different alloys such as Cast Iron, Aluminium, Steel in CNC Machines / Lathe Machines/ Milling Machines (Computerised Numerical Controlling Machine). The main advantage of Carbide Insert is it works faster and that result in more finishing of the Components.

Inserts are used for different application like Boring, Turning, Curve, Grooving, Milling Etc. Every insert codes has its meaning in itself , Now we will go step by step and understand the decoding.

End mills are metal work cutting tools that can create shapes, holes, and shave down a working material for milling and a variety of other applications. These other processes include profiling, contouring, reaming, drilling, and more. These cutting tools feature carved, sharp edges at their tip and along their circumference. These edges allow them to carve out the face and sides of your milling material. End mills are specifically designed to be able to cut on an axis, which sets them apart from other milling bits. And while some specifically designed end mills can drill into a surface, make sure not to confuse them with drill bits.

Milling is a machining process that removes mass from your working piece of metal or other manufacturing material. Milling machines use rotary cutters, which contact this working material and shave away bits of metal as it advances. Milling processes are some of the most customizable in all metal machining, as you can vary the pressure of the contact, direction, axis, and switch out cutting heads when needed. Because it offers so much customization and control, milling is one of the best ways to perform precise cutting jobs. Milling has two major categories: face milling and peripheral milling. Face milling cuts flat surfaces across the top or bottom of your workpiece, while peripheral milling carves out material using the outside circumference of the cutting tool. One of the types of cutters used here is the end mill.

So, How was the Decoding, didn't you find it simple, even if you have any doubts , Please reach out to us at Hello@jaibros.com. Our Technical Team will assist you to make the selection easily.

What is Turning, Milling , Grooving, Threading insert Grade, Angel, Specification, Dimension, Full form, Geometry, chart.

0086-813-8127573

0086-813-8127573