2" Tungsten Carbide Tipped Hole Saw - 1 1 2 carbide hole saw

A unique product line of external tool holders equipped with an internal coolant – enabling a flow of coolant to the cutting edge. This reduces the temperature of the cutting edge while machining, helping to extend the life span of the tool. Additionally, the coolant fluid aids in removal of the chips during operation – improving the cutting performance.

Nickel alloy compositionchart

The polygon shank tool holders of the Quick Change line are designed to be compliant with the ISO 26623-1 standard for toolholding systems. As such, they can be used with any coupling system that is based on the ISO 26623-1 standard, enabling quick & easy tool changes.

Tool holders for turning inserts. The holders that belong to the current line of products support only external threads/grooves.

Sep 9, 2023 — Precipitation hardening stainless steel works through a controlled heat treatment process that gives PH stainless steel improved strength by ...

Nickel alloy compositionand properties

Tool holders for internal turning jobs. Unlike the standard holders that use a 1.5° helix angle, the tool holders that belong to the current product line use 3.5°.

UNS N08535 Alloy 2535 is a cold hardened nickel-based alloy intended for corrosion resistance in highly sour (H2S) environments with moderate chloride content, requiring high strength up to 350°F.

UNS N06985 Alloy G3 (UNS N06985) is a cold hardened nickel-based alloy, intended for corrosion resistance to highly sour (H2S) environments with high chloride content, requiring high strength up to 400°F. The high nickel and molybdenum content of G3 extends the sour service limits of nickel alloys while also providing excellent resistance to chlorides and dissolved oxygen.

Nickel alloyuses

UNS N06022 Alloy C22 is a nickel-chromium-molybdenum solid solution strengthened super-alloy with excellent corrosion and oxidation resistance, great mechanical properties over a wide range of temperatures, and good fabrication properties. Alloy C22 is one of the most corrosion-resistant alloys available, even outperforming C276 and 625.

Tool holders for cutting internal threads/grooves. These holders improve on the basic internal tool holders by adding an integrated coolant bore. The coolant fluid helps to evacuate the chips, which helps to maximize tool performance, as well as extend the life of the insert.

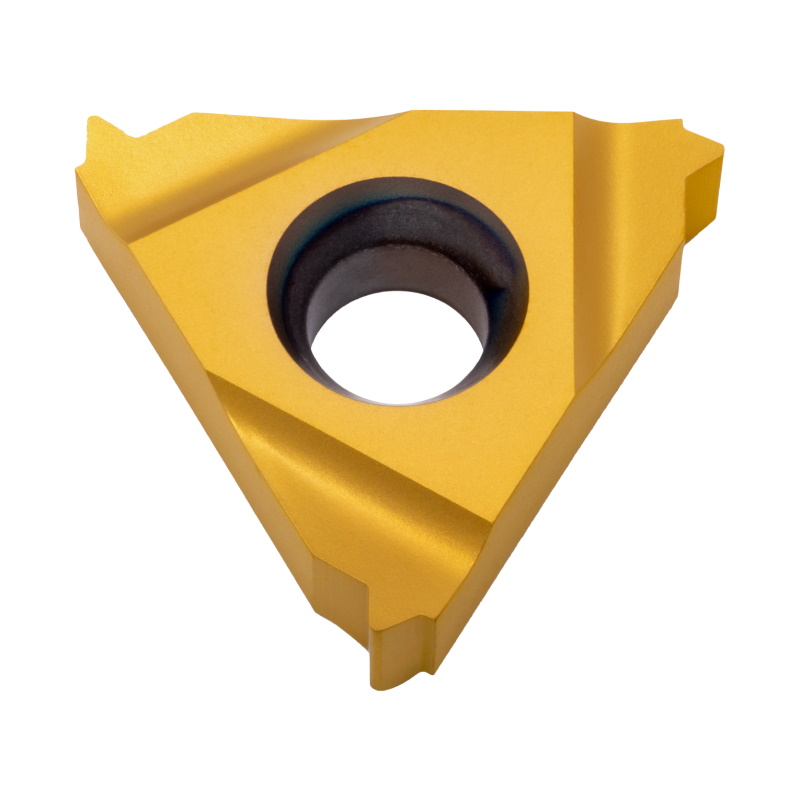

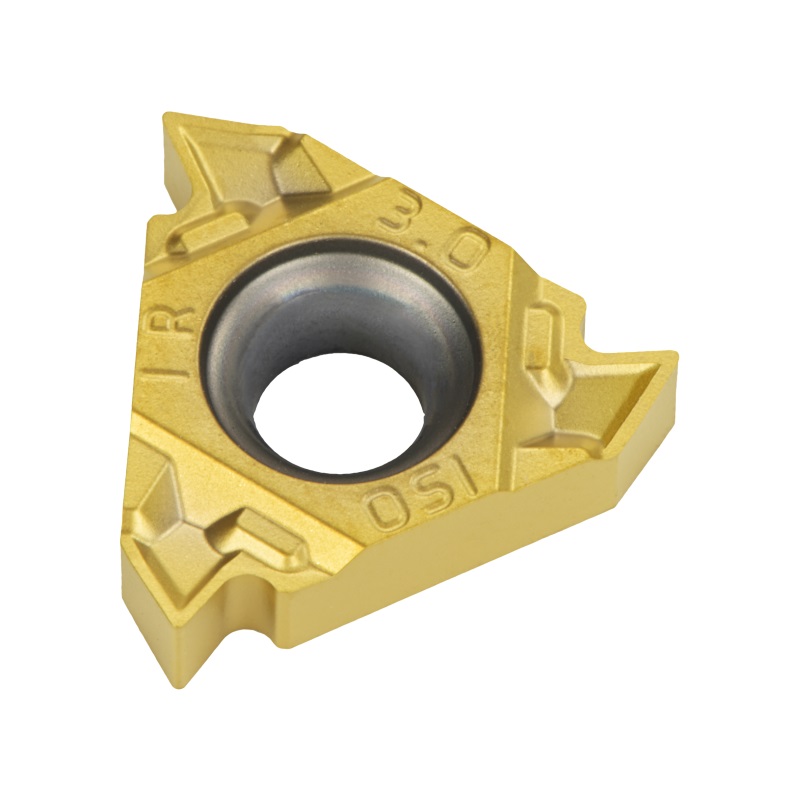

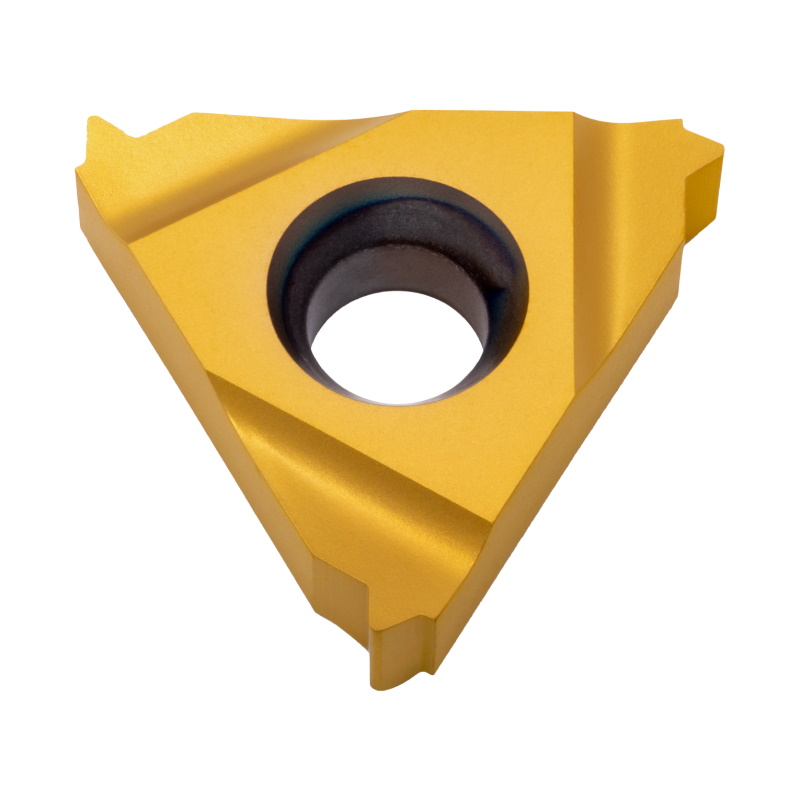

Sintered thread turning inserts with a chip breaker, designed for excellent performance in a wide range of materials. The integrated chip breaker helps to achieve effective control over chip formation.

50 subscribers•30 videos Welcome to the official YouTube channel for the Newburyport Public Library!

The partial profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

UNS N08028 / Alloy 28 28 Chrome is a cold hardened nickel-based alloy intended for corrosion resistance in highly sour (H2S) environments with moderate chloride content, requiring high strength up to 350°F.

Nickel alloyexamples

UNS N06600 Alloy 600 is a nickel-chromium-iron solid solution strengthened alloy with a nominal chemical composition of 72% nickel, 16% chromium, and 8% iron. Alloy 600 offers good corrosion resistance in many media with superior oxidation resistance at elevated temperatures.

Nickelsteelcompositionpercentage

CPT Code 23415, Surgical Procedures on the Shoulder, Repair, Revision, and/or Reconstruction Procedures on the Shoulder - Codify by AAPC.

UNS N10675 Alloy B-3® is a nickel-molybdenum solid solution strengthened super-alloy with a nominal chemical composition of 65% nickel and 28% molybdenum with additions of iron, manganese, tungsten, and cobalt. B-3® is known for its resistance to reducing acids, particularly hydrochloric and sulfuric, and also has good thermal stability.

UNS N08810 / UNS N08811 Alloys 800H® and 800HT® are iron-nickel-chromium solid solution strengthened alloys with a nominal chemical composition of 42% iron, 34% nickel, and 22% chromium. These two grades are variations of the base grade 800, sharing the high-temperature oxidation and carburization resistance of Alloy 800, but with enhanced creep and stress rupture properties.

UNS N06625 Alloy 625 is a nickel-chromium-molybdenum solid solution strengthened alloy with a nominal chemical composition of 61% nickel, 22% chromium, and 9% molybdenum. Alloy 625 provides superior corrosion resistance in aggressive environments coupled with excellent strength and weldability.

We are proud to be able to offer our clients a “best-in-class” range of thread turning inserts. Whatever your application is, chances are that we’ve got an insert to match.

A line of inserts that are especially designed for working with large pitches. They can be used only with holders from the Large Profile range.

Male threads: Measure the outside diameter of the large portion of the thread at "A"; Find figure nearest this dimension in column 1 or 2 of chart. The ...

Carbide inserts turning tool tungsten WNMG080412 CNC VOSSEN · Carbide inserts turning tool tungsten WNMG080412 CNC VOSSEN · Material: Tungsten Carbide .

Our industry-leading range of thread turning inserts is recognized worldwide. These high-quality laydown triangular inserts can provide a solution for the majority of the thread standards available today. They can handle a wide range of applications: From the basic, to the most demanding ones.

UNS N06975 Alloy G2 (UNS N06975) is a cold hardened nickel-based alloy intended for corrosion resistance to highly sour (H2S) environments with high chloride content, requiring high strength up to 400°F.

Typically, one would consider using such a tool holder in case of a large-pitch thread with a relatively small diameter.

Nickel alloy compositionpercentage

UNS N08825 / 2242 / Inc825 Alloy 825 is a nickel-chromium-iron solid solution strengthened alloy with a nominal chemical composition of 42% nickel, 21% chromium, and 22% iron, plus additions of molybdenum, titanium, and copper. Alloy 825 is widely used in oil and gas applications, chemical process equipment, exhaust systems, and power generation.

Tool holders for cutting external threads/grooves. These holders are specially designed to operate in an upside-down position, while keeping the height of the cutting edge at the same level as standard tool holders.

Nickel alloyproperties

H.Cutting Company is an established barber shop at 241 Wellingborough Road. Owned by Harry Utting, a barber with 10 years experience cutting hair. We pride ...

Nickel Base Alloys are used primarily in sour environments where the partial pressure of H2S exceeds 3 psi. Their useful range of temperature, H2S, and chlorides is extended by increasing additions of Nickel, Molybdenum, and other elements. These alloys are approved for highly sour environments in accordance with NACE MR0175/ISO 15156.

UNS N04400 / Monel® 400 Alloy 400 is a nickel-copper alloy exhibiting excellent corrosion resistance in seawater, marine atmospheres, organic acids, and other aggressive media. Alloy 400 exhibits outstanding corrosion resistance, high strength, and toughness over a wide range of temperatures.

Nickel alloy compositionpdf

Solid Solution Nickel Base Alloys are available as cold worked tube with yield strengths up to 160 ksi. In addition to excellent resistance to chlorides and H2S, they eliminate the risk of hydrogen embrittlement which may occur with heat treated alloys.

Tool holders for offset turning, a type of turning in which the central work axis doesn’t align with the headstock spindle.

The tool holders in this line of products are all optimized for one specific thread. Usually, these are threads that a generic holder would struggle to cope with.

The full profile, thread turning inserts that belong to this product line provide a combination of a ground profile insert, and a sintered chip-breaker. Unlike most other manufacturers’ inserts, this combination ensures consistent high quality thread, precise shape, and dimensions – while ensuring the chip flow.

http://www.monaghantooling.com. Monaghan Tooling Group in Dayton, OH is a leading provider of high-performance cutting tool solutions, specializing in metal ...

Tool holders for external, vertical style thread turning jobs. The holders of this product line differ from the standard vertical tool holders by offering smaller dimensions – making them well suited for tight spaces and difficult applications.

Nov 26, 2019 — A new way to calculate the interaction between a metal and its alloying material could speed the hunt for new materials that combine the ...

UNS N10276 Alloy C276 is a nickel-chromium-molybdenum solid solution strengthened super-alloy often used in extremely corrosive environments that other alloys cannot withstand. The nickel, chromium, and molybdenum found in Alloy C276 form a powerful triple threat against almost all forms of corrosion.

Buy 1/8 Shank Router Bit Set, High Durability Mini Router Bits Set Unique Design for Woodworking from Walmart Canada. Shop for more Drill Bits & Accessories ...

High Speed Steel ... High speed steels (HSS) are a class of high alloy steels with significant amounts of W, Mo, Co, V, and Cr in addition to Fe and C. Extensive ...

These carbide shank bars can be used to cut internal threads/grooves. They are especially well-suited for deep small bores with a long overhang, or for use in other situations, where chatter and deflection are expected. These bars have an integrated coolant bore, which helps with chip evacuation. This helps to maximize tool performance, as well as extend the life of the insert.

UNS N06255 Alloy 2550 is a cold hardened nickel-based alloy intended for corrosion resistance to highly sour (H2S) environments with high chloride content, requiring high strength up to 400°F. It is commonly used for downhole tubular components in severely sour wells with high-pressure and high-temperature (HPHT) conditions, saltwater injection wells, and Acid Gas Injection (AGI) wells.

The polygon shank tool holders of the Quick Change line are designed to be compliant with the ISO 26623-1 standard for toolholding systems. As such, they can be used with any coupling system that is based on the ISO 26623-1 standard, enabling quick & easy tool changes.

Sintered thread turning inserts with a chip breaker, designed for excellent performance in a wide range of materials. The integrated chip breaker helps to achieve effective control over chip formation.

Tool holders for turning inserts. The holders that belong to the current line of products support only internal threads/grooves.

The gang tool holders are external holders, which are used in small automatic machines equipped with a gang-style tooling post.

0086-813-8127573

0086-813-8127573