20 Types of Drill Bits -Which One Is Right for You? - types of drill bits for metal

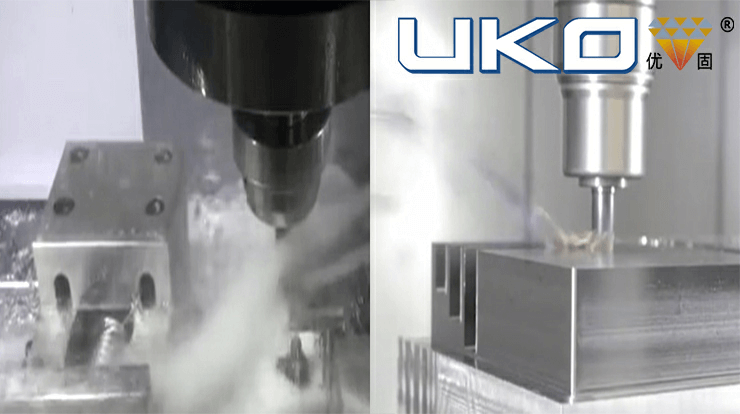

UKO turning tools and milling tools are very popular especially the CNC high-feed milling cutter and planer type milling insert is widely loved by customers at home and abroad. Welcome to inquiry.

Once tracks are install in the perimeter of the room, the next step is fitting a layer of padding on the wall. Then the fabric is stretch using a variety of tucking tools. We offer several fabric on wall spatulas for the insertion of the fabric. These specialized hand tools fulfill specific tasks.

Specially design for inserting the fabric at the Clean edge system™ track. The spatula has a quarter circle form. Hold it in your hand, move the wrist back and forth to make a rocking motion. A handy tool to use along ceiling or delicate molding. Made from white plastic only. It does not leaves any markings on frames.

UKO turning tools and milling tools are very popular, especially the CNC high-feed milling cutter is widely loved by customers at home and abroad. Our CNC tool holders are jointly developed with the cooperative enterprises, which are highly compatible with our inserts. Welcome to inquiry.

Class n refers to uncured aluminum, refined alloy, casting alloy, copper alloy including easy cutting steel, brass, electrolytic copper.

The roller is used at the final stage for a clean edge finish on straight lines. After the fabric is correctly placed on the wall and trimmed to the minimum.

The perfect and necessary tool for tucking a fabric into the CES or Clean Edge System™. Use this spatula with a rocking motion. It is the best upholstery fabric on wall tool ever created for clean edge wall upholstery. This fabric tucking tool works on all track systems on walls and ceilings.

For fast fabric tucking, we have a speed roller. The upholstery tool rolls in the clean edge track system inserting the fabric quickly.

The packaging of carbide inserts usually have a lot of information, including the brand logo, insert model, grade, work piece(PMKNSH) recommendation, cutting parameters references…What does this information on the package mean? Let’s take a look at how to distinguish this information.

Design and build in USA by Clean Edge System. Solid wood handle has a large opening to fit big hands. View the fabric tucking tool video.

It is a must have on a wall upholstery job along with the metal spatula or Ergo spatula. A useful small tool to finish inserting or pushing the fabric in tight and narrow space. Excellent quality and well made upholstery tool when working with Clean edge tracks ( C.E.S. or B.B. tracks).

CNC inserts can be divided into metric (ISO) and inch (ANSI) standards. The main difference lies in the number in the middle. In addition, different tools have different expressions.For example ISO: CNMG120408PS, ABSI: CNMG432PS

Another tool in the list, Plastic spatula has similar shape as the metal. But it is not use at the beginning of the installation. After the fabric is in the correct place and trimmed down all around the edges. Only then, you need to finish tucking the fabric in the track. The plastic protects the frames from any damages.

For example, the basic metal spatula has a large plate with a short and flat top handle.This product is essential for working with the fabric and the track. Get severals if you work on large ceilings or just one if you prefer! Consequently, an installer has a powerful tucking tool in hand during a fabric application on the wall.

In cemented carbide, the cutting range of p-type products refers to carbon steel, cast steel, including 0.25-0.25% C quenching and quenching and tempering, easy cutting steel including annealing and quenching and tempering, low-carbon alloy steel containing less than 5% gold, high-carbon alloy steel, cast iron, and tool steel, including annealing and quenching and tempering series.

Our catalog of products has a wall upholstery tool kit of heavy-duty items. The set of tools includes 2 fabric tuckers, one rocky, one speed roller, one bay leaf including a plastic spatula.

Next upholstery tool is the Bay leaf spatula. The narrow plate has a shape of a leaf and works well in case of small spaces.

Class H refers to the cutting hardness range of blade in hardened steel, Cast Chilled Cast Iron, hardened cast iron, etc.

Class s refers to iron base superalloy, super alloy material contains nickel base and cobalt base, titanium base and titanium alloy.

The hardness of cemented carbides can be divided into ferrite, pearlite gray cast iron, nodular cast iron, pearlitic ferrite malleable cast iron.

We also have a wall upholstery tool kit. The set has 6 fabric on wall spatulas. If you are interested in the kit, it has a large rocker, a straight head spatula, a bend head, the bay leaf, a Speed Roller and the standard plastic.

The insert grade is not standard like the tungsten carbide raw material, such as K10, K20, K30… The insert grade is different from companies to companies.

0086-813-8127573

0086-813-8127573