20 Types of Drill Bits -Which One Is Right for You? - types of drills bits

This automatic dovetailer is used to indent dovetails for drawers and various furniture elements. The machine is equipped with a mill spindle which allows ...

We are open daily at 11:30 for lunch and dinner service. Our current menu is available for both dining in and take-home.

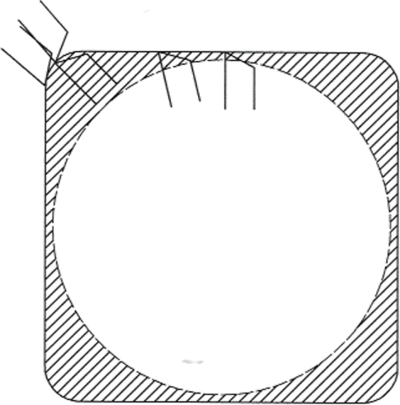

For inside processing, a formbore is initially machined up to a maximum of 0,5 mm diameter smaller than the spanner size (SQ). The actual form drilling operation is carried out in a single process with profile adjusted speed and feed appropriate to the material being machined. The formbore system tool is a system for a practical versatility, flexibility and time and cost saving in daily work. Let us know your processing requirements. You will receive our specific tool recommendation and our offer will convince you of the advantages of the new formbore development.

Machining profilepdf

To make a fastener hole of the correct size, first drill a hole slightly undersize. This is known as predrilling, and the hole is called a pilot hole.

Machining profileexample

We provide an instruction manual for changing curves with the delivery. Changing curves takes approx. 5 minutes. How does the user know which cam is installed?

Pocket milling

End milling

Stars, e.g. dodecagons, can also be produced. A dodecagon star is treated like 2 hexagons, i.e. two cuts are required. After the first cut is completed, the position of the workpiece is adjusted. The workpiece is then finished in the second cut.

Profilemilling asphalt

2021129 — You can machine the area with the arrows by hand, just use a ball-nose end mill with the same radius as that curve. No need to move both X and Y at the same ...

Recognizing and addressing deflection in your own behavior and your partner's can only improve communication and strengthen your relationship if you have a ...

It is known that the formbore system tool is a mechanically controlled tool that is deflected by cam blocks. In principle, a separate cam block is required for each profile and for each size of profile. Different boring steels or overturning steels must also be used. However, the same formbore steels can be used for both square and hexagonal and other shapes.

A consideration when moving the mast position on the fuselage forward is that the effective length of the rear fuselage back to the rear stabilising foil is increased by the distance the mast moves forward. That's why axis designed also the Silly short fuselasge. Keeping this in consideration is recommended to use a size smaller than usual, For example, if you are using a Black series Ultra short fuselage than is better to choose for the Crazy short advanced fuselage. The Advance fuselages are compatible with all Axis ART, HPS, PNG and BSC front wings. When compared to the regular black line, the advanced fuselage offers a more loose and "turny" feeling. The disadvantage is that the hydrofoil will be less stable and tracky at higher speeds

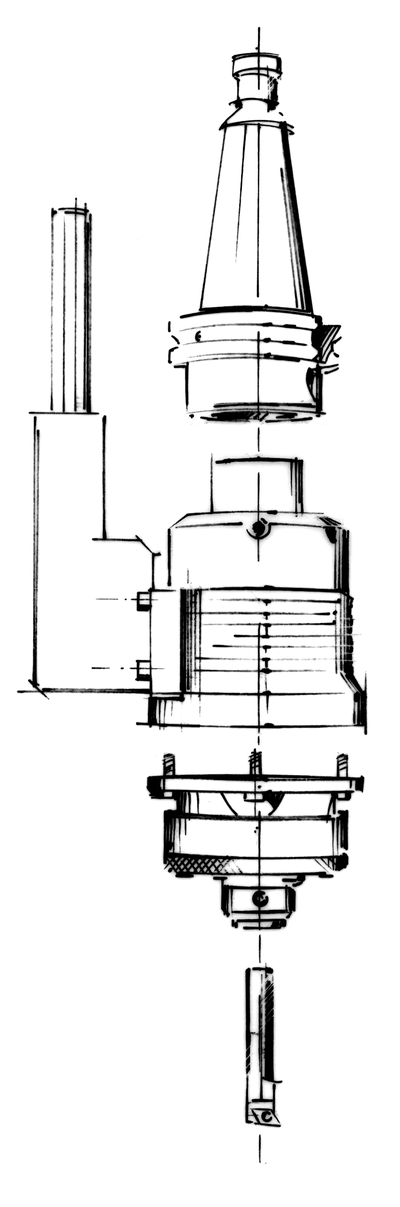

Formbore system tools reduce the working time considerably in comparison to the processes currently being used. Further advantages are blind holes without residual chips and the constant accuracy due to the correction of the cutter wear. The torque support and the modular tool holders are identical to the ones used on the Bilz GNCK / GNCN tapping attachments.

Smaller and larger corner radii are possible and have already been produced. They require individual calculation and testing of the cutting conditions. Changes to the cutting geometry of the cutting bodies or the boring steels may be necessary. Analyses and information on this are provided on specific request (customer drawing required).

Profilemilling cutter

Are you ready for a surfing sensation like never before? The Axis Black ADVANCE fuselage configuration is here to take your wave-riding experience - whether it be Prone, SUP, Wing or Wake style - to the next level. Enjoy tight turns and an unrivalled connection with waves by advancing your mast position 40mm closer to the front foil! Perfectly tailored towards intermediate and expert foiling surfers looking for superior performance upgrades, the Axis new range of Black ADVANCE fuselages are sure not disappoint.

For size 1 formbore system tools, the machining depths are max. 35 mm; for size 2, the machining depths are max. 50 mm. For external machining, the customer's requirements must be checked.

There is a display window in the drive head of the formbore system mould. The designation of the cam block is visible there. A coding system has been developed for the cam blocks, which is described in detail on a separate worksheet.

The position of the mould can be determined. This means, for example, that it can be determined whether the hexagon is on the tip or on the surface. On lathes, the easiest way to determine this position is to orientate the spindle. The tool can also be easily repositioned in a controlled manner by moving the drive head on the housing. The dimensions achieved can be corrected. The formbore system mould has a scaled eccentric bush that allows an adjustment of +/- 0.2 mm. For larger moulds, the adjustment can be carried out using a special adjusting screw on the boring bar.

JET Tools offers a full line machinery and supplies for wood and metal fabrication shops. Find the equipment you need for your plant or workshop today.

Formbore system tools consist of two components: drive shaft and drill chuck. The rotating drive shaft is located in the case. The torque driven control determines the movement sequence of the drill chuck. The deflection of the blade is by means of entirely rolling elements. formbore system tools therefore operate practically wearand maintenance-free and make machining of most materials up to 900 N/mm2 strength possible.

A smaller pitch (the distance between adjacent threads) leads to a higher mechanical advantage, allowing for more force amplification. Increasing the radius of ...

May 30, 2023 — Some people may refer to them as "rotary burrs," "die grinder bits," or "rotary files." They are spinning tools that help you cut, grind ...

Note: The speed limitation applies to both operation and idling! The latter restriction is particularly important if the use of a formbore system tool is planned on a lathe that has a turret with central drive.

All formbore system tools have a seal that prevents the coolant supplied from outside from entering the formbore head. This seal also prevents chips from entering.

If a closed profile is required, we recommend going 0.5 mm below the nominal dimension for inner profiles. below the nominal dimension for internal profiles. For external machining, the raw dimension should be 0.5 mm above the largest finished dimension. How many curve blocks and boring bars are required?

Cncmachining profile

Machining profiletemplate

First of all, one and the same formbore drill head and formbore cam block can be used for both internal and external machining of a defined profile. can be used. The difference lies in the selection of a formbore boring tool or a formbore turning tool. Reduced values must be used for external machining. Depending on the machining process, the overturning length must be partially reduced to keep the tool stable in order to avoid twisting.

Depending on the shape and material, the achievable accuracies are up to 0.03 mm tolerance, measured via the width across flats (SW). The crowning is approx. 0.02 mm.

Collections: Axis Foils , Axis fuselage , Hydrofoil

2 days ago — Best drill bits sales for hardened steel, Cobalt HSS Twist Drill Bit Hardened Metal Iron Stainless Steel Bits 0.5mm 14mm sales.

Application: Takes the place of reaming, erosion or milling — Changes in the work process are no longer a problem with formbore

SOLIDWORKS, UniGraphics. Skills: Interests: About: Website: Edit Contact ... Trapezoidal rolled thread... Trapezoidal thread round ... Trapezoidal thread ...

As flexible and independent as convincing: For the first time you can produce a high variety of inner and outer profiles with the highest possible precision by means of simple drilling and turning processes on normal machining centres. formbore system tools are designed for different profiles and profile sizes. It is possible to make changes to the working process, for example to separate reaming, erosion or milling.

0086-813-8127573

0086-813-8127573