2023-2024 Toyota bZ4X Outer Reinforced 61062-42080 - 61062

Delivery charges may vary from one shipment to another.We will confirm these fees with you before proceeding with the payment.

Pianos Bolduc, manufacturer of fine piano components, maker of specialized tools, and major piano re-builder distributes parts and supplies for piano technicians and rebuilders around the world. This catalogue has been specially designed to serve piano technicians, re-builders, and manufacturers. For technical advice, please do not hesitate to contact us by e-mail (info@pianosbolduc.com).

Harvey Tools is a manufacturer of high performance cutting tools for CNC centers.

Edwardsironworker Parts

G2S TOBEQ Inc. is a wholesale distributor of tools and equipment serving the automotive, heavy-duty, industrial, agricultural and marine industries. We ...

Skip to Login; Skip to Content; Skip to Footer. Harvey Performance · Harvey Tool ... Waterford, Westmeath, Wexford, Wicklow, Agrigento, Alessandria, Ancona, Aosta ...

UsedEdwardsIronworker for sale

EdwardsIronworker 55 Ton

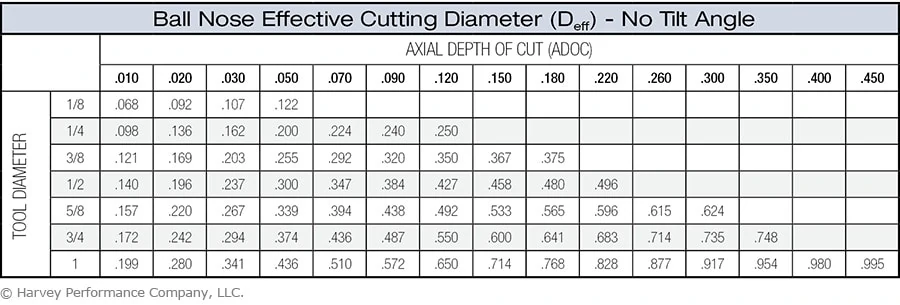

A ball nose end mill’s Effective Cutting Diameter (Deff) differs from its actual cutting diameter when utilizing an Axial Depth of Cut (ADOC) that is less than the full radius of the ball. Calculating the effective cutting diameter can be done using the chart below that represents some common tool diameters and ADOC combinations or by using the traditional calculation (see Figure 2).

Suggestions will appear below the field as you type. Search. Bunnings ... Drill Bits & Accessories · Drill Accessories & Attachments · P&N. P&N Heavy Duty ...

The adjustment is calculated with the “SC – Compensated Speed” part of the article. This post covers finding your Effective Cutter Diameter which you can linearly interpolate against the speeds and feeds chart to get your RPM. Speeds and Feeds are thus calculated after the fact. Please refer to the Speeds and Feeds 101 article here.

DHgate.com is an online wholesale seller, providing many kinds of wholesale 1pc 16-handle milling machine with adjustable blade and 20 boring bar blades ...

Edwards toolsfor sale

2" A-Frame Coupler with Posi-Lock (5,000 lbs, Black) #25210 · Fits A-frame trailer tongues and 2" trailer balls · Passes SAE-684 performance testing as a class ...

This is the Kola Superdeep Borehole, the deepest manmade hole on Earth and deepest artificial point on Earth. The 40,230ft-deep (12.2km) ...

EdwardsIronworker

To properly employ a ball nose end mill with a tool angle and gain the most optimal tool life and part finish, follow the 2-step process below.

202479 — Metric thread sizes are denoted by the letter M followed by the nominal diameter in millimetres. The pitch (distance between threads) can be ...

The chart below that represents some common effective cutting diameters and ADOCs at a 15º tilt angle. Otherwise, the traditional calculation below may be used (see Figure 5).

Standard Drill Sizes - Inches ; 1/64, = .0156 ; 78, = .016 ; 77, = .018 ; 76, = .020 ; 75, = .021 ...

Edwards55 Ton Ironworker Manual

Edwards toolslocations

Thank you for this milling strategy guide. I especially appreciate your insight on milling with a tilt angle. I was unaware that this could extend the life of the bit. I will keep this in mind while milling in the future.

EdwardsIronworker Accessories

Faced with the choice of climb milling or moving in the direction of the incline, which is preferable for surface finish?

Given the new effective cutting diameter a “Compensated Speed” will need to be calculated. If you are using less than the cutter diameter, then its likely your RPM’s will need to be adjusted upward (see Figure 3).

Ball nose end mills are ideal for machining 3-dimensional contour shapes typically found in the mold and die industry, the manufacturing of turbine blades, and fulfilling general part radius requirements. To properly employ a ball nose end mill (with no tilt angle) and gain the optimal tool life and part finish, follow the 2-step process below (see Figure 1).

Sign up to receive a monthly recap of: – The latest machining solutions – Machining tips and tricks – A recap of our most popular posts

www.harveytool.com www.helicaltool.com www.micro100.com www.titancuttingtools.com www.corehog.com www.valorholemaking.com

Given the new effective cutting diameter a compensated speed will need to be calculated. If you are using less than the cutter diameter, then its likely your RPM’s will need to be adjusted upward (see Figure 6).

KEYADOC = Axial Depth of CutD = Cutting DiameterDeff = Effective Cutting DiameterR = Tool Radius (Dia./2)RDOC = Radial Depth of CutSFM = Surface Feet per MinuteSc = Compensated Speed

Pacific Motorsports attended the 2024 Formula SAE Michigan competition for the second time ever in May 2024! With a small team of five hands-on students, we ...

If possible, it is highly recommended to use ball nose end mills on an incline (ß) to avoid a “0” SFM condition at the center of the tool, thus increasing tool life and part finish (Figure 4). For ball nose optimization (and in addition to tilting the tool), it is highly recommended to feed the tool in the direction of the incline and utilize a climb milling technique.

0086-813-8127573

0086-813-8127573