24202 Virginia Income Statistics | Current Census Data for ... - 24202 zip code

INDR 1010 - Industry Readiness A crucial component of trade practice is the ability to share information. Explaining work, applying trade skills and meeting industry standards involves communicating effectively. This course introduces these skills with a trade focus and will help prepare students to contribute to employment and in the classroom. Course work may tie directly to projects and assignments happening elsewhere in the program and in its shops.

First, lookup the recommended surface speed in Table 1 (V ≈ 625 ft/min) and calculate the spindle speed from Equation 2:

PRMA 1001 - Drills, Drill Presses and Grinders This course introduces machine shop drilling and grinding machines including sensitive, upright and radial arm, and drill presses, as well as the safe practice for the use of these machines and their attachments. Course materials include adjusting, repairing and maintaining these machines and their accessories, various drilling tools and drill sharpening. The course introduces the selection, handling and safe use of cutting fluids.

Note: when applying oil manually, scale the feed and speed back to 60%, so N ≈ 420 rpm and f ≈ 4.8 in/min (final answer). This is close enough to 500 rpm that I would first try this tool at the low end of high range with good oil application and see how it goes.

PRMA 2003 - Turning Operations II This course builds on the skills and knowledge gained in Turning Operations I. Theory and project work covers the use of the lathe and carbide tools in turning between centres and taper turning. Learners use common set-ups and procedures for lathe operation.

PRMA 2002 - Milling Operations II This course builds on the skills and knowledge gained in Milling Operations I. Theory and project work will cover will cover information pertaining to indexable carbide tooling and more advanced work holding methods and set-ups.

PRMA 1000 - Safety, Tools and Basic Measurement Safety is the first consideration in machine shop operations. This course will introduces learners to general shop safety, safe rigging practices, WHMIS and Occupational Health and Safety. Course activities enable learners to identify common machine shop hazards, perform safe rigging for the machine shop, and understand their rights in safety matters. This course will also cover safe use of the common hand tools and devices used in machine shop work. Learners will be taught how to select the proper tools and demonstrate the correct use and maintenance of those tools. Course material introduces the theory and use of common machine shop semi-precision and precision measuring tools, both metric and imperial. Care, maintenance, adjustment and calibration of these measuring tools are addressed.

SAFE 1001 - Introduction to NS OH&S Act This course offers students an introduction to the Occupational Health & Safety (OH&S) Act of Nova Scotia, which is required by any person employed in a Nova Scotia workplace. This is a generic, introductory course that provides basic knowledge of the Act for students and is considered to be the basis from which more specific training can be given.

SAFE 1000 - Introduction to WHMIS (Workplace Hazardous Materials Information Systems) This course offers learners basic overview of WHMIS principles and establishes a solid foundation to support workplace-specific training on the safe storage and handling of controlled/hazardous products. Upon successful completion of the course, students receive basic WHMIS certification.

Machining definition in manufacturing

* multiply feed values in table by 0.5 for difficult to machine materials, flexible toolholding or workpieces, or lighter-duty machines*

Machining examples

Every metal cutting operation requires selection of proper cutting parameters for success. As a DML TA, you need to understand basic calculations that will allow the tools you use to work as intended.

Machinists produce precise parts based on technical engineered drawings. You learn how to do this by operating conventional hand-controlled methods, including:

Note that these speed and feed values are guidelines assuming proper (flooded) lubrication, workpiece stiffness and depth of cut. When applying oil manually (as in the lab), scale the feed and speed back to 60%, so N = 570 rpm and f ≈ 18 in/min (final answer). Note also this problem assumes we peripheral milling versus plunge milling (since we never teach the students the latter in lab).

These are some of the courses offered in this program. It is not a complete list and courses are subject to change in advance of the academic year.

TIP2: When drilling deeper holes (> 3xD) without high pressure TSC (thru spindle coolant), reduce spindle speed an additional 50%.

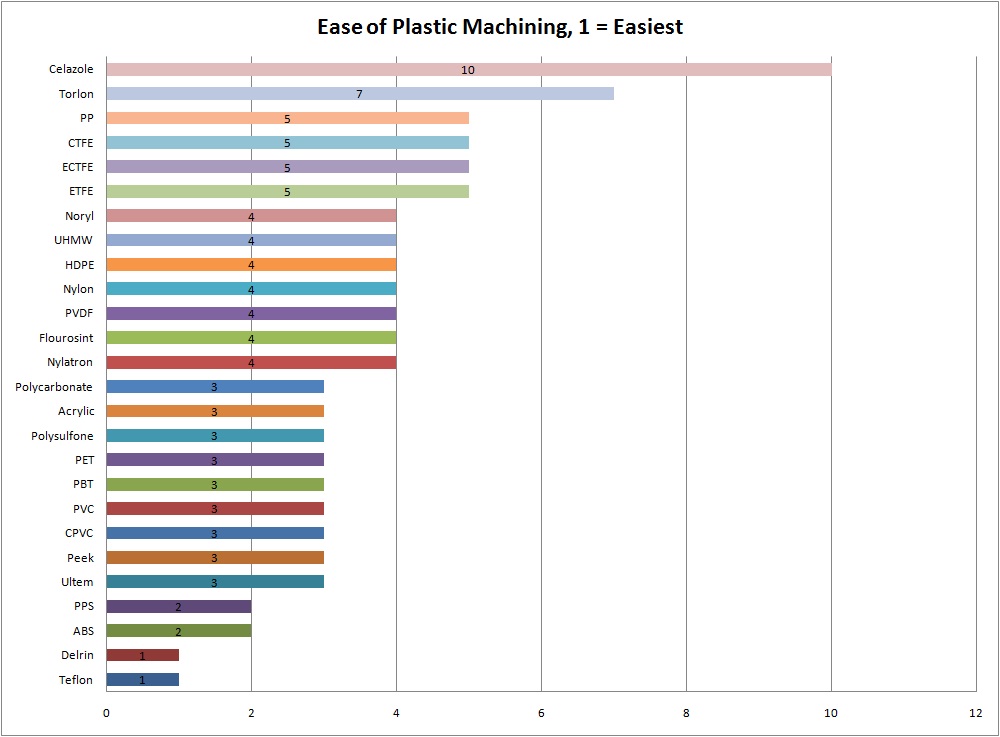

As you can see Acetal (Delrin) is one of the most machinable plastics and nylon is four times less machinable (which is why it should usually be avoided!).

TIP2: Do not plunge an annular cutter at a feedrate less than 0.001 ipt (inch per tooth) in strain hardening materials like 304 stainless or titanium.

PRMA 2000 - Engineering Drawings II This course is designed to provide learners with the technical skills to interpret detailed engineering drawings. Learners are instructed in the application of tolerances, fits, threads and sectional views for the production of machined parts.

PRMA 1004 - Milling Operations I This course introduces learners to basic milling operations. Course material includes milling machine operation, set up, maintenance and machine construction. Learners have the opportunity to apply safe methods of operation of the milling machine and practice milling operations in the shop.

In addition to annual tuition, there are program costs (books, tools, etc.) and student fees for College services, health and dental plans, your student association and parking.

TIP1: Recommended peck depth when drilling less than 3xD (e.g. 3 drill diameters) with flooded coolant is one drill diameter, or when applying oil manually, or under low pressure, is 50% of drill diameter.

WORK 1100 - Workplace Mentoring I This unit of instruction is designed to assist learners in managing their learning as an apprentice in the workplace. Learners will study their own experiences with learning new skills and identify their own learning preferences as an aid to developing learning strategies.

TIP: When working with plastics with good machinability, use the cutting parameters for aluminum up until the point that the plastic melts.

Note that these speed and feed values are guidelines assuming proper (flooded) lubrication, workpiece stiffness and depth of cut. When learning how to use the CNC, always start lower (around 60% on the spindle speed and feedrate override buttons) and work your way up as you gain confidence or purchase your own tools (lol).

TIP: Countersinking should generally be performed at 25% of the speed and the same feed per revolution as the equivalent sized drill.

Machining process

First, lookup the recommended surface speeds in Table 1 (VALUM ≈ 625 ft/min, VSTEEL ≈ 250 ft/min (notice the 2.5 multiplier))

First, lookup the recommended surface speed in Table 1 (V ≈ 250 ft/min) and calculate the spindle speed from Equation 2:

PRMA 2004 - Introduction to Computer Numerically Controlled Machining This course provides a basic introduction to modern machining methods used with Computer Numerically Controlled (CNC) machine tools. Course material covers the operating principles and basic procedures, terminology and coordinate systems. Projects reinforce shop safety and add the safety considerations specific to CNC machine tools.

First, lookup the recommended surface speed in Table 1 for a 1 HSS endmill cutting aluminum (V ≈ 250 ft/min) and calculate the spindle speed from Equation 2 using the aforementioned 75% speed reduction:

Please begin by reviewing the comprehensive course document on this topic, as it clearly explains the process of calculating these parameters for drilling and milling operations. The governing equations are summarized below.

While this program focuses on hand-controlled methods, you also learn the fundamentals of computer numerical control (CNC). With CNC, a computerized machine is programmed to do detailed work and automation.

Next lookup the recommended feed per revolution for the equivalent size drill bit in Table 2 (fr ≈ 0.006 in/rev) and calculate the feed rate using Equation 3:

PRMA 1005 - Engineering Drawings I This course gives the learner an overview of engineered drawings and their use in the Machinist trade. Course material includes engineering lines and symbols, parts and types of drawings and their purpose. The course also introduces sketching. Learners develop the ability to interpret drawings for use in the accurate machining of parts.

INDR 1020 - Working Effectively in the Trades Almost all trades professionals will need to work well with others. Students in this course will learn to be effective team members and adapt and analyze how they share information with others. A selection of activities relevant to the particular trade will be used to practice collecting, analyzing and using trade information. Course work may tie directly to projects and assignments happening elsewhere in the program and in its shops.

Example 4: Calculate the speed and feed for a 1″ diameter, 6 flute HSS annular cutter in ¼ thick aluminum on a manual milling machine in the lab.

PRMA 2001 - Introduction to Precision Measurement This course builds upon Introduction to Measuring Tools I and covers of all forms of measuring devices and methods, both metric and imperial, used in machine shop work. Using all types of measuring tools with confidence and reliability is one of the machinist's primary skill sets. Course material covers the theory and use of machine shop precision measuring tools. Learners practice proper care, maintenance, adjustment, calibration and use of these measuring tools.

Develop skills to interpret engineered drawings and use precise measurements and hand tools to create custom parts and perform repairs with conventional hand-controlled methods.

Your program overview is on the way. While you wait, feel free to browse our list of Programs & Courses or visit our Admissions information section.

Next, lookup the recommended feed per tooth (chipload) in Table 3 (ft ≈ 0.008 in/tooth) and calculate the feed rate using Equation 3:

CNC machining

TIP: Reamers should generally be run at half the spindle speed and twice the feed per revolution of the equivalent sized drill bit.

Machining is a critical part of industrial production. Many businesses and sectors rely on machinists to maximize overall performance and output.

Machining process steps

Note: since applying oil manually, scale the speeds back to 60%, so NALUM ≈ 1425 rpm and NSTEEL ≈ 570 rpm (final answer). Note these are MAXIMUM values and lathe chuck safety must take precedence; spinning the lathe chuck at 570 rpm is about the upper limit of what we safely do in the lab, so for smaller or easier to machine workpieces, DO NOT EXCEED 600 RPM regardless of the calculation results, unless you are running a collet chuck.

Next lookup the recommended feed per revolution for the drill bit in Table 2 (fr ≈ 0.004 in/rev) and calculate the feed rate using Equation 3:

Types of machining process pdf

Note that these speed and feed values are guidelines assuming adequate (flooded) lubrication, workpiece stiffness and drill depth less than 3 drill diameters (0.75″). When applying oil manually (as in the lab), scale the feed and speed back to 60%, so N = 450 rpm and f = 3.6 in/min (final answer).

SAFE 1021 - Safety Basics – Hazard Identification The learners are introduced to the types of hazards encountered in workplaces and the approach that should be followed when recommending and implementing appropriate controls. Two key elements of Hazard Identification are addressed: Hazard Assessment and Inspection. The Nova Scotia Occupational Health and Safety Act is discussed. The course material is to be infused throughout the curriculum and may be delivered in the classroom, shop or other opportunity as designed and developed by the instructor.

TIP: IF this was being performed on a CNC lathe, typical parting feed rates vary between 0.001 in/rev (for steels) and 0.005 in/rev (for plastics). But remember, do NOT use the power feed when parting on a manual lathe unless you own the machine!

Example 2B: Calculate the speed and feed for a 1/2″ diameter, 3 flute carbide endmill if peripheral and plunge cutting in aluminum using a CNC milling machine in lab.

Example 5: Calculate the speeds for parting off 1 diameter aluminum and 1 diameter mild steel workpieces on the lathe using the standard carbide part-off inserts.

First, lookup the recommended surface speed in Table 1 (V ≈ 250 ft/min) and calculate the spindle speed from Equation 2:

PRMA 1100 - Work Experience The work experience component provides the learner with an opportunity to apply new skills and concepts appropriate for entry-level positions within the machining and manufacturing industry. Learners will assess their own performance and be evaluated by an industry partner. Learners will identify personal outcomes they wish to attain during the work experience and will keep a journal.

PRMA 1007 - Mathematics II Learners are introduced to mathematical problems commonly encountered by machinists. Topics include formula applications, plane geometry, and trigonometry, with the emphasis on the solution of problems relating to a wide range of shop applications.

SAFE 1023 - Safety Basics – Lock-out Tag Out Lock-out Tag Out introduces students to the hazards related to energized systems and procedures to ensure worker safety. Related legislation and risk management is discussed and the student is exposed to the various types of lock-out devices. The course material is to be infused throughout the curriculum and may be delivered in the classroom, shop or other opportunity as designed and developed by the instructor.

Example 3: Calculate the speed and feed for a HSS countersink used to countersink a #10 clearance hole in aluminum using a manual milling machine.

TIP: Plunging should generally be performed at 75% of the speed and 25% of the feedrate of the calculated peripheral cutting parameters.

PRMA 1006 - Mathematics I This course will reinforce basic mathematical concepts and operations used in machining. The topic areas include whole numbers, fractions, ratio and proportion, rectangles and triangles, regular polygons and circles, solids and metric measure.

First, lookup the recommended surface speed in Table 1 (V ≈ 100 ft/min) and calculate the spindle speed from Equation 2:

Next, lookup the recommended feed per tooth (chipload) in Table 3 (ft ≈ 0.004 in/tooth) and calculate the feed rate using Equation 3:

Next, calculate the feed rate used for plunging. Remember annular cutters should be fed at approximately 25% of the feedrate for an equivalent sized endmill. From Table 3, lookup the recommended feed per tooth for a 1″ HSS endmill (ft ≈ 0.008 in/tooth) and calculate the plunge feed rate using Equation 3:

Note that these speed and feed values are guidelines assuming adequate (flooded) lubrication, workpiece stiffness and drill depth less than 3 drill diameters (0.75″). When applying oil manually (as in the lab), scale the feed and speed back to 60%, so N = 900 rpm and f = 3.6 in/min (final answer).

Note that these speed and feed values are guidelines assuming adequate (flooded) lubrication and workpiece stiffness. When applying oil manually (as in the lab), scale the feed and speed back to 60%, so N = 330 rpm and f = 2.0 in/min (final answer).

TIP1: Since annular cutting is a plunging operation, it should generally be performed at 75% of the speed and 25% of the feedrate of the calculated peripheral cutting parameters (as with endmill plunging).

Machining pronunciation

View detailed program fees page(s). Please note that amounts on these pages are meant for planning purposes only. They don't represent final amounts owing.

A general rule of thumb for materials which are strong enough to support the drilling process is that fr is between 1 - 3% of the drill diameter, depending on the material strength.

Recognizing prior learning / transfer creditsIf you have previous learning (course, employment, etc...) that's relevant to your program, you may be able to apply to earn credit. Not all programs are eligible. Learn about our recognizing prior learning (RPL) process.

What is machining in Engineering

PRMA 1003 - Turning Operations I This course introduces learners to metal cutting lathes and their operations. Course material covers lathe operation, set-ups, maintenance and machine construction. The course offers learners the opportunity to practice safe methods of operation of the lathe in the shop.

Example 2A: Calculate the speed and feed for a 1″ diameter, 4 flute HSS endmill in aluminum using a manual milling machine in lab.

The table below contains a recommended surface speeds for common materials when using DML equipment. These values are conservative because our primary goal is fostering a safe learning environment (for our users and our tools!), not trying to squeeze every second out of each operation.

0086-813-8127573

0086-813-8127573