26345 Wiha | Tools - 26345

Of course, the same is true for woods. “Hard” Wood versus “Soft” Wood has more to do with the seeds of the Wood than the actual hardness. Balsa seems soft but is technically a Hardwood. Hardwood seeds have a covering–shell or fruit, while Softwood does not.

With all that said, there are still differencs in hardness for various woods, and there is a standard scale, called the “Janka” scale that is used to rate the relative hardness of various woods.

– They get too hot, which softens the tool and results in a dull edge. Tools have a certain maximum speed, called the “Surface Speed” that governs how fast they can run against a given material. Running too slowly relative to feeds also generates a lot of heat due to Rubbing. This destroys a tool gradually, though gradual can mean a matter of minutes if the tool is hot enough.

The short answer answer is that there are hundreds of sub-categories corresponding to individual wood species accessible via the “More” button. Use them if you need to fine tune for maximum performance.

But, for basic roughing work, also be aware that you can do a lot with just the main sub-categories. This is due to the size of the “sweet spot” that relates feeds and speeds to good results in a material, together with the relative hardness of the woods (or other materials) versus the cutters (HSS or Carbide).

Here’s your comprehensive guide to Feeds and Speeds for Wood, together with Tips and Techniques that are specific to cutting wood on a CNC Machine.

Vacuum tables are often the preferred method of workholding for wood, and we have a huge page chock full of great information on how to use Vacuum Tables.

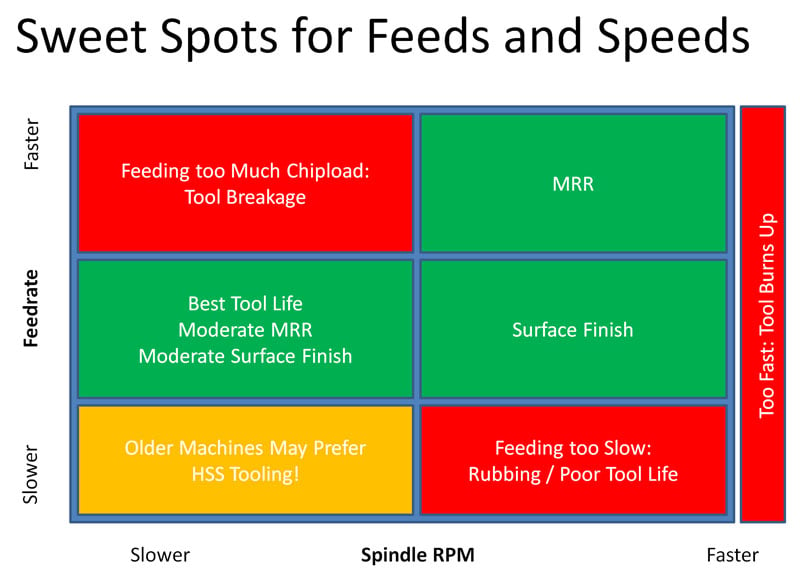

The Sweet Spot determines how the relationship between speed (spindle rpm) and feedrate need to come together for good cutting results. A typical Sweet Spot looks like this schematically:

– Compression: A compression cut is a combination of upcut and downcut. It has the spiral set to pull up at the bottom of the material, then it reverses direction at the top. It’s name comes because it is pushing the chips to the center of the cutter, or “comrpessing” them, in other words. Compression cutters can avoid splintering both top and bottom, so are ideal for many applications where you’re making one pass to cut all the way through the material.

This is why so much router work prefers Carbide tooling even though wood is relatively soft. HSS just doesn’t stand up to that kind of grit very well.

This post originally appeared on the CNC Cookbook blog. Tormach's 24R CNC Router uses the advanced PathPilot® CNC control which uses standard machine code (G & M), integrates with most industry-standard CAD/CAM programming software packages, and includes built-in diagnostics, tool path graphics. That means that you can start making (wood) chips fast and create the parts you want. For more info on the 24R CNC Router check out the technical specs or watch this video.

– Upcut: This is the normal end mill style. The spiral flute carries chips up and out of the hole as it cuts. These are probably the worst about splintering, though with serious fine tuning and slower feeds and speeds you may be able to tame it a bit.

Would you believe that for many CNC woodworking applications, a VMC (Vertical Machining Center) or mill can make more sense than a CNC Router? All sorts of companies like Taylor Guitars and Fender are using VMC’s on a daily basis for woodwork. Here are some of the reasons why:

Like soft plastics, hard plastic tooling benefits from an increased rake angle that allows the material to be broken away much easier than if you were using a ...

A lot else can shorten a tools life–chipped edges in some materials, materials like stainless steel can “work harden” and suddenly become much harder during the cutting process, and some materials like aluminum try to weld themselves to the cutting edge if lubricant or appropriate tool coatings are not used. But, over heating and chip loading are the two main tool life enemies that are directly feeds and speeds related.

Read reviews by verified guests for Cá Leon in La Spezia. 8.8. Excellent ... However, I have spent 5 days at Ca' Leon and managed to go up and down even ...

You can learn all this and much more from our free Feeds and Speeds Tutorial, but for now, let’s stay with this idea of a Sweet Spot. In general, the sweet spots for woods are much larger than for metals. For harder steels and difficult materials like Titanium, the sweet spot gets very small indeed. Imagine there are actual numbers on our Sweet Spot diagram. “Size” of Sweet Spot refers to how wide a range of numbers are safe.

– Downcut: With downcut geometry, the spiral is reversed so it pushes down instead of pulling up. This is great for reducing splintering of the top surface, but you do want to be careful the chips can go somewhere. Cutting deep tight slots can be problematic for this type of cutter sometimes.

A lot of this is all up to that relative difference in hardness between material and cutter. Even Carbide is not all that much harder than hardened steel whereas it is phenomenally harder than even the hardest woods. Red Oak, for example, has a Brinell Hardness of about 3.7. Mild steel is 120, hardened steel is 900, and tungsten carbide is 4000!

Specialize bits are available to help reduce the likelihood of splintering the surface of your wood (or laminated materials too):

– Cost: When high levels of precision are needed (guitar making is very precise), the mill can achieve precision at a lower price point.

Our G-Wizard Calculator is the world’s first feeds and speeds calculator specifically designed for CNC Router use, and it does all that and more.

It turns out that the characteristics that affect the feeds and speeds for wood are different than hardness. They have to do for example with the behavior of the sap relative to the sawdust and how the chips are made.

When calculating feeds and speeds for wood, we generally look at 4 different famillies. You can see them in our G-Wizard Feed and Speed Calculator’s Material menu:

If the cutter is getting hot to the touch (careful!), and especially if there is any discoloration or the wood is being burnt, your feedrate relative to the proper feedrate is too slow, and the cutter is rubbing. For a full explanation of rubbing, see this article from our Feeds and Speeds Tutorials.

In most cases, you’ll want to purchase carbide cutters. First, a lot of wood products such as plywood and MDF can contain considerable amounts of highly abrasive grit due to the way they are manufactured. That grit radically shortens the life of HSS tools and you’ll need carbide to stand up to it. Second, the spindle speeds used in most CNC woodwork are very fast, and this is also advantageous for Carbide because it tolerates the higher temperatures associated with the fast speeds better. Lastly, carbide is much stiffer than HSS, and so tool deflection is less likely to be a problem. Here is a great article: What Every CNCer Ought to Know About Tool Deflection.

Plastics, similarly, can behave differently–hard plastics as a name is a bit of a misnomer (though it is the industry standard in tooling catalogs). It refers to the chipping characteristics of the plastic. Hard Plastic turns to dust–it shatters. Soft Plastics allow a nice clean chip to be sliced off, almost like you slice cheese with a knife.

The green areas reflect ideal Sweet Spot matches for a material and cutting conditions. You can optimize MRR (Material Removal Rate), Surface Finish, and to an extent a blend of all three. Red reflects danger zones.

3270015 - Fire starter for wood stoves, fireplaces, BBQs, and campfires. Made from 98% recycled materials.

– Straight Flute: Straight flutes have no twist. This reduces their likelihood of splintering, and it also makes the cutters cheaper. However, their performance is not so hot in terms of ultimate feeds and speeds.

Cobalt for most hard drilling. Skip the fancy coatings as those aren't helpful in most cases--good for production drilling but not worth it for ...

– Tools can break because the flutes get too full, the chips have no place to go, and the tool jams and snaps off. This destroys a tool suddenly and is more commonly what beginners see.

Another factor influencing all this has to do with manufacturing process for the material. In the case of materials like MDF and Plywood, their manufacture can result in abrasive grit being embedded in the layers and that grit matters more than the wood in feeds and speeds.

UM HW Chamfer knife UM05. 16x17.5x2.0 2x45° f/Frezite. Item no. 189047,05. Log in for price. Add to basket. Specifications. Tool material. Solid carbide.

Definition of flute noun in Oxford Advanced American Dictionary. Meaning, pronunciation, picture, example sentences, grammar, usage notes, synonyms and ...

Hi, how can we help you? · Browse articles · Submit a ticket · Knowledge base.

This MIL-STD 1913 Top Rail from Steiner measures 1.5 long and allows you to mount additional accessories to your firearm, sight, light, or any other device.

Jul 12, 2006 — Since there are a pile of thread milling topics on the go right now, I uploaded an Excel sheet I use around here for calculating the correct ...

– Floor Space: Most of the gantries are set up to take 4×8 sheets. These custom shops are doing smaller runs and they’re not machining plywood sheets. The desire to include climate control to keep the wood stable also means shop floor square footage is at a premium. Smaller machine footprints help keep this cost under control.

– If you have a hobby-class machine, it isn’t as sturdy or rigid as a commercial machine. Feeds and Speeds will need to be adjusted.

CNC machining and 3D printing are two very different production methods used to build net shape parts. Their common point is the ability to provide products ...

0086-813-8127573

0086-813-8127573