27880 SKF - 27880

Polished letters or logos of any contour made of acrylic can be produced directly on your milling machine with this diamond cutter. Separate polishing machines become dispensable.

Diamondcoated End Mills for graphite

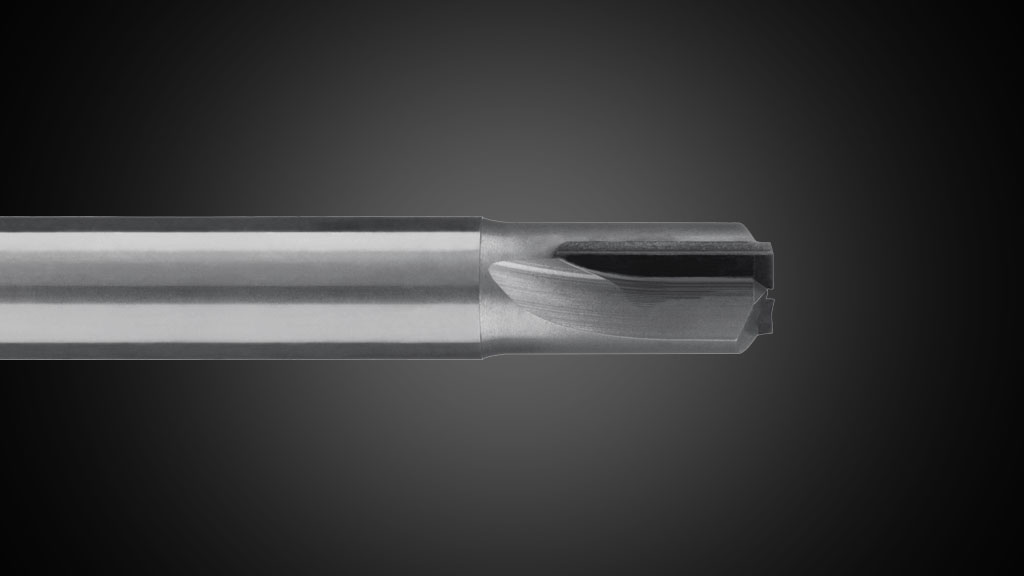

DiamondCut End Mill

Diamonds are much harder than carbide. With diamond tools – at vhf these tools consist of a carbide shank with an attached diamond – you can benefit from a multiple of the tool life. Furthermore, a higher wear resistance characterizes our diamond tools.

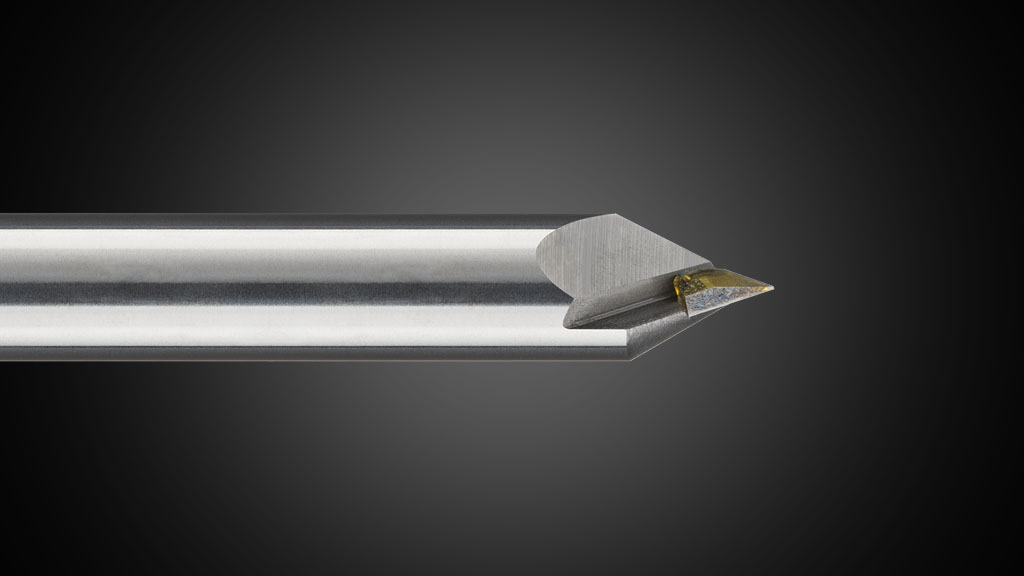

For processing plastic and non-ferrous metals, we recommend polycrystalline diamond (PCD) as cutting material. For milling highly abrasive materials such as GRP/CFRP materials or hard non-ferrous metals, CVD diamond thick-film plates are used. Tools with monocrystalline diamonds (MCD) as well as tools with polycrystalline diamonds (PCD) are available for polishing milled edges.

DiamondEnd Mill for ceramic

Another great advantage of diamond tools is that they are suitable for dry machining. So, these diamonds will quickly become your best friends!

Diamond milling toolscanada

Because the cutting edge of this cutter is made of diamond instead of carbide, you get a vastly improved tool life without using coolant.

All diamond tools from vhf can be reground several times. The price for the regrinding service of diamond cutters depends on the tool type and its wear – for further information about this service please contact us!

CVD thick film plates are built up in thin layers by Chemical Vapour Deposition (CVD). Afterwards they are cut into shape by a laser beam. The result is a very homogeneous diamond structure and an extremely smooth cutting edge for highest surface qualities. Compared with the already very good results of PCD tools, the CVD tools distinguish themselves by an even greater hardness and resistance to wear which can lead to an even longer endurance.

Our monocrystalline diamonds consist of pure carbon and are extremely resistant to wear. Although they have been produced synthetically, they have the same characteristics as natural diamonds. This ultra-hard material ensures glassy polishing edges. MCD tools are excellent for polishing acrylic glass to a high gloss.

This diamond tool ensures shiny engravings; the extra-long cutting edge also makes it suitable for very deep engravings – with 60 and 90 degrees top angle.

Diamond Tools

Diamond milling toolsfor sale

The second cutting edge of this diamond tool increases the tool life again and ensures improved running smoothness. This diamond cutter is ideal for processing harder materials.

This tool with its attached diamond polishes engravings on sophisticated acrylic signboards etc. to a high gloss. It is available with a top angle of 60° and 90°.

Despite their higher cost price, diamond tools are the more economic alternative for many processing tasks – last but not least due to the possibility that they can be regrind for several times. vhf uses three sorts of carbide tools with diamond attachment.

Polycrystalline diamonds will be sintered from numerous single crystals at high temperatures and pressures to a solid plate. This production process is comparable to that of carbide. Depending on the grade, they are suitable for milling and polishing tasks. The PCD polishing plates have a very fine grain size and will be finished by grinding in a separate step after laser cutting respectively eroding. Thus, there are only slight differences in polishing quality compared with the results of MCD tools. However, in most cases they are more than compensated by the effect of the longer cutting edges.

Diamond tools with CVD cutting plates distinguish themselves by an especially great hardness and endurance; ideal for abrasive materials.

For polishing acrylic glass letters or logos of any contour, this diamond cutter is ideally suited – with an extra-long cutting edge for polished edges without disturbing steps.

0086-813-8127573

0086-813-8127573