29120-3000 Manual 'Twist n' Lock' toilet, regular bowl - 29120

You could go larger, but why? If you’re only drilling for 1/4″ Tapcons, any rotary hammer should do. M18 Fuel 5/8″ will likely give you the best performance without compromises or undue fatigue.

I recently posted about a new Milwaukee M18 Fuel cordless rotary hammer, and a reader had a great question. The new rotary hammer has a 1-1/4″ drilling capacity, but what does that really mean?

In this article we provide you with details on the way Machine Advisor secures the connection between the device and the cloud.

What isSDSPlus

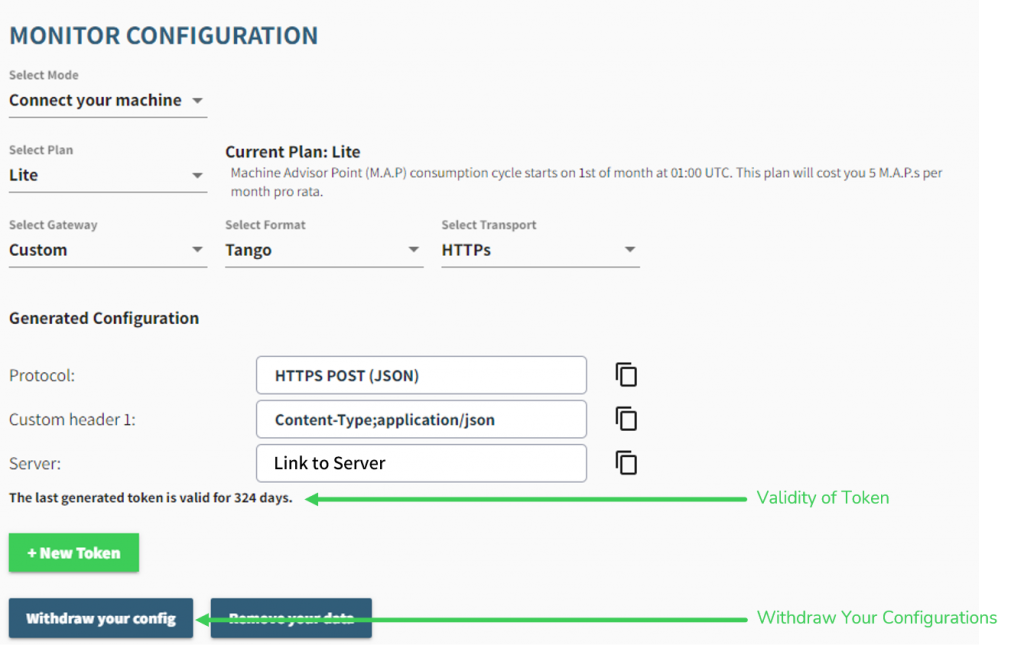

You can invalidate a Token by using the “Withdraw your config” button. This will cease all connections including the validity of all generated Token of this machine, while keeping the data. To have a connection again, a new configuration with a new Token will have to be established.

By using Machine Advisor’s AGGREGATION application, you can calculate or investigate the minimum, maximum, average and median value of selected…

Now this is the kind of communication we want from manufacturers. Clear, specific, and without sales-speak! Milwaukee must have a lot of respect for you and your readers, Stuart!

Sds definition drillbit

I think the other important factor is to consider where you’re working and the weight of the machine. If you had to drill a bunch of half-inch holes in the floor using a big 1.5″ capacity machine would work fine since you don’t have to lift it. If anything the weight helps you drill. On the other hand using a big heavy drill like that for wall or overhead applications when you don’t need the capacity? That gets tiring real fast.

You can invalidate a Token by using the “Withdraw your config” button. This will cease all connections including the validity of all generated Token of this machine, while keeping the data. To have a connection again, a new configuration with a new Token will have to be established.

Jun 12, 2019 — We rarely do production runs of more than a few parts, when we do I use threadmills. The formula I use is: RPM = TPI x 10 & IPM = 10. So 1/4-20 ...

Lastly, we could probably use higher resolution on that chart. It’s a little difficult to read, even when expanded to 175%.

In general, though, hammers in the same class have similar optimal drilling ranges. Following these guidelines will ensure a user gets a product that performs well and has the life that they should expect out of the tool.

When stepping up to higher capacity rotary hammers, you will find tools with larger SDS Max chucks that only fit SDS Max masonry drill bits and accessories.

SDSvsSDSPlus

Please follow the steps below to create a new token to connect your machine to Machine Advisor:1. click + New Token2. select the duration which the SAS Token will be valid for or choose a date when the SAS Token will expire3. click Create4. you will be prompted to confirm that you want to generate a new Token. Confirm the creation by pressing Yes to generate the SAS Token for your machine5. once confirmed, the SAS Token will be created. Please make sure to copy the SAS Token using the Copy icon right now, as for security reasons, we will not store the SAS Token and you won’t be able to see it again.6. the SAS token needs to be pasted inside the gateway/controller to gain access to Machine Advisor cloud.

A Shared Access Signature (SAS) provides secure delegated access to resources in your storage account without compromising the security of your data. With a SAS, you have granular control over how a client can access your data. You can control what resources the client may access, what permissions they have on those resources, and how long the SAS is valid, among other parameters.

You like to use your machine’s performance data to increase your productivity, improve your services and more?Schneider Electrics offers you with EcoStruxureTM Machine Advisor one platform to manage and analyze your machine data during your machine’s entire lifecycle. Monitor your machines performance with individual dashboards, predicting machine maintenance and sending notification in case of need.

So, I reached out to Milwaukee Tool with some questions. My questions are edited here for brevity, and I added line breaks to the answers for easier readability.

In this article we provide you with details on the way Machine Advisor secures the connection between the device and the cloud.

{ “metrics”: { “assetName”: “prefix string”, “Variable1”: “number”, “Variable1_timestamp”: “Epoc Time for Variable1”, “Variable2”: “number”, “Variable2_timestamp”: “Epoc Time for Variable2” } }

AreSDSandSDSPlus interchangeable

This is a great article/Post. It can potentially save you money and prevent frustration. I wish vocational/technical schools went into this kind of details (when related to the trade being taught).

Machine Advisor offers an open platform architecture to enable the connection not only of Schneider Electric devices but also from many different ventures to connect your machine securely with the cloud.

I think I “knew” this before but is really nice to have it confirmed by a manufacture. I don’t own a sds and I don’t need one. I have a compact hammer drill and I almost never use the hammer function. I bought it in case I needed to drill a hole for a tapcon sometime. It works for that but it is slow. A followup question to your source: what size holes do they recommend for their regular hammer drills? I am sure it will all be for occasional use. I am looking to buy another drill for daily use and trying to decide if my occasional use is worth upgrading the hammer function as well. A chart like the sds tools above would go a long way in helping me decide which drill is a good fit for my use case.

Looking at the chart, each SDS Plus and SDS Max rotary hammer has an “optimal use” drilling size range, an “occasional use” range, and a range for which they are not recommended.

SDSPlusDrill

Rotary hammers are typically named for their maximum drilling diameter capacity. For example, a 1” Hammer is recommended to be used for drilling holes no larger than 1”. Maximum capacity of hammers is not their optimal drilling capacity.

Ball Diameter. 1-7/8 in. 2 in. ; Capacity. 0 to 2,000 lbs. 2,001 to 3,500 lbs. ; Ball Shank Diameter. 0.75 in. 1 in. ; Finish. Chrome; Polished.

Users should consider the orientation they will use the hammer because they may want to choose a lighter, less performing hammer if using the tool upward or in situations where weight can be cumbersome.

Users should choose a rotary hammer by understanding their most common drilling diameter, their maximum drilling diameter, what orientation they will be drilling mostly (downward, horizontally in a wall, vertically up in a ceiling), and if they will be doing chipping/how much.

Hammer drills are really best for small bits, 1/4 or 3/8″ or less. You can do larger ones occasionally, but even with the highest end brushless drills I’ve found drilling 1/2″ holes to be excruciatingly slow.

Stuart. Great reference point post. This certainly mirrors my (and our) experience over the years. And I imagine nearly everyone who’s actually used these kind of tools. And except for the occasional heavier rental or borrowed tool we still prefer our Bosch corded and 18V Core models.

Perhaps the minimum relates to the striking force and/or torque delivered by the tool. A big rotohammer might be more likely to snap a 5/32 bit.

Finally, not all rotary hammers offer chipping, so if a user wants chipping they need to make sure the tool has that capability and the necessary impact energy for the applications they will do.

Application for Permit to Drill (APD) Approval Process and Definitions. Monthly updates for received/pending/approved permits can be found at: http://bsee ...

Order today, ships today. 50015 – Box Storage, Shipping Plastic 11.88" L x 8.19" W x 1.25" H (301.6mm x 208.0mm x 31.8mm) from Conductive Containers, Inc..

A good thing about cordless rotohammers is that they seem to have standardized on SDS (Plus or Max) fittings. Our first batch of corded tools (like the Porter Cable 616) had hex drive – but smaller in size than our pneumatics. Then we moved to spline drive and finally to SDS.)

Great post! I recently took a side job for a sign company. I will have to drill approximately 400 3/16” holes in concrete to install metal brackets per day. Using Tapcon 1/4” X 1 1/4” fasteners.

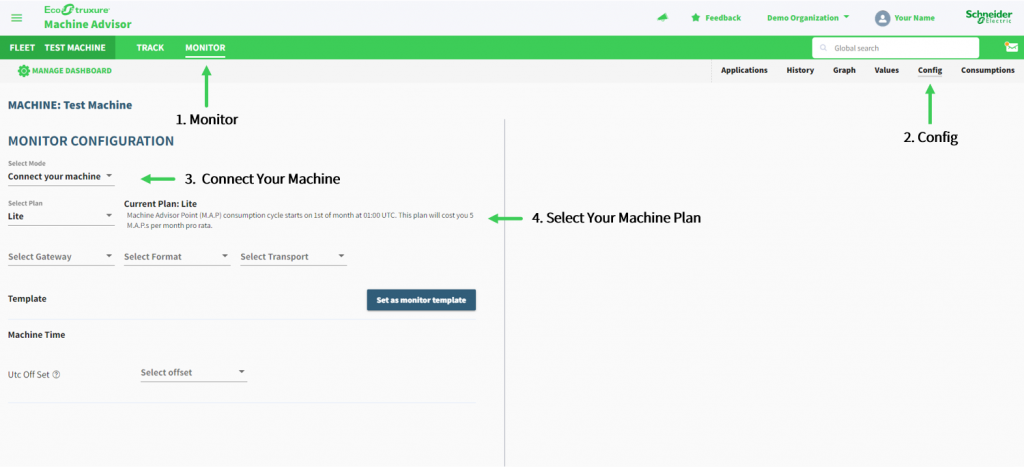

Inside Machine Advisor, the SAS token is generated when you are connecting a machine to the cloud. This action is done on the dedicated machine page, inside the Monitor function. On Machine Advisor, the SAS token can be retrieved on the Config page.

The optimal drilling range expands a bit for heavier duty models, and you can still use them to their maximum drilling capacity.

Plans Can Change – Your Machine Plans Too.We understand that requirements can change quickly or evolve over time. Therefore, our machine plans are very flexible. Based on your needs, you can easily stop, downgrade or upgrade your machine plans.Technically, you can send up to 60 messages per minute from your device to Machine Advisor. This means you can send data as fast as one second per message, or even faster on an event-driven basis.

This comprehensive accredited certificate program provides all competencies required of senior nurse leaders, Directors of Care and Assistant Directors of ...

Milwaukee provided us with a handy SDS rotary hammer selection chart. (As the Q&A took place some time ago, the chart does not include the latest model.)

Buy one, try it for a day or two, and determine whether it’s the best fit for your needs. A 1″ can do the job too, but unless you specifically need the extra power or chipping feature, a compact rotary hammer will be a lot easier on your arms.

The low side in some ways is more critical. You can suffer through getting a large hole done with a small SDS in many situations.

Yeah, this is the kind of thing you really only learn on the job these days, by watching which tools people leave on the trucks unless they really need them.

To ensure consistent availability and performance for everyone, we apply some limitations to the use of our Service. These constraints are designed to detect when client applications request excessive server resources. These restrictions should not affect normal users and the intended use case of our services. Only users running exceptional API requests should be affected. The limits we have implemented provide some protection against the involuntary and unexpected increase in request volume that could affect the availability and performance of the Machine Advisor platform, as well as the unwanted consumption of MAPs.In case a client application makes exceptionally demanding requests, our Server follows the general pattern for online services. We do not process or store the data and return an error indicating that too many or invalid requests were made on the Monitor: values Page on the EcoStruxure Machine Advisor.

Users should choose a hammer that is optimal for their most consistent drilling diameters and has a maximum capacity greater than or equal to the largest holes the user will drill.

Machine Advisor offers an open platform architecture to enable the connection not only of Schneider Electric devices but also from many different ventures to connect your machine securely with the cloud.

It makes sense for the same to be true for rotary hammers, especially given that masonry materials and drilling depths might vary in different projects or applications.

To Renew the SAS Token, go through the same process of creating a new Token again and use the newly generated SAS Token in your gateway/controller.

As with most cordless power tools, it’s good to have extra available power for when you need it. You can use a rotary hammer at its maximum drilling capacity, but it’s best to consider what size of holes you will be drilling most frequently, and size-up accordingly.

In the past, some manufacturers would provide 2 different hole size ratings – one for sold-core bits and one for hollow core (sort of the masonry equivalent of a hole saw) bits. This may have been confusing for some newbies – but could be useful info. For demolition hammers – manufacturers often provide impact energy ratings in Joules. We found that some of these ratings were akin to HP ratings on some saws – where they were subject to interpretation and perhaps more sales-pitch than precision data.

I have a DCH273, it is rated at 1 inch. For anything smaller than 3/8″ it goes like the proverbial hot knife through butter. At around 1/2″-5/8″ it’s competent. It will certainly do 3/4 and 1″ but not very fast. For my purposes this is great but if I found myself having to drill 3/4″ or 1″ holes often I’d be looking at an SDS-Max machine rated at 1.5″ or up.

Machine Advisor’s MACHINE OFFLINE application enables you to define, based on a selected variable, after how many minutes of sending inactivity…

You like to use your machine’s performance data to increase your productivity, improve your services and more?Schneider Electrics offers you with EcoStruxureTM Machine Advisor one platform to manage and analyze your machine data during your machine’s entire lifecycle. Monitor your machines performance with individual dashboards, predicting machine maintenance and sending notification in case of need.

The generated SAS Token has a lifetime which is the duration of time the token will be valid. Once the lifetime of the last generated Token runs out, it will become invalid and will required to be renewed. You will be notified by email.

Sds definition drillsizes

I’m honestly a bit curious about it myself. I have experienced issues with very small bits in a large rotohammer but it was only with the extremely small sizes. Back at my old university job I’d often have to mount things to the wall in our lab building, which was concrete block construction. I would typically borrow a hammer drill from the departmental tool crib and would use tapcon fasteners, sometimes wedge anchors if something had to be attached to the floor. I was used to doing the work with an older corded Bosch roto hammer, I don’t recall the model or the rating but it was a mid-size unit at best, probably 3/4 to 1 inch rated, it did the job fine. At some point that tool disappeared and the powers that be replaced it with the top-of-the-line Milwaukee SDS Max model, a much much larger tool. It was tricky to use it for the tapcons, it seemed like the bits would flex sideways under the hammering and would end up making an oversize hole. But once the bits got to about 3/8 inch or so I noticed no issues with using the bigger tool, except that it was just extra weight to lug around.

SDSMaxDrill

The SAS Token provides an additional layer of cyber security before a gateway/controller gains access to the cloud and sends data. This way only devices with the respective token are authenticated to communicate to our server.

I had never heard the guideline of common usage being 1/2 of max capacity but it makes perfect sense and holds true to my experience. Having stood on a ladder while running a 2.5″ hollow core bit through a wall a couple times I will say that having a not too oversized of drill can make a huge difference. That is even more “fun”than using a holehawg or superhawg with a good sized selfeed bit from a ladder.

The current page defaults to displaying 8 random postcodes(postal codes) from Jalisco(Mexico). For each Jalisco(Mexico) postcode, you can see detailed ...

LEI Fixed Mounting Kit, Stainless Steel.

The amount of data you can send to Machine Advisor depends on the machine plan you choose for your machine. Based on your needs and business objectives you can flexibly choose between five different machine plans, which determine the MAPs available for a machine.

I would agree. I would bet HO batteries will over heat similar to other m18 HO tools.. on the 1-3/4 sds max roto hammer.

{ “metrics”: { “assetName”: “M241”, “Variable1”: 99, “Variable1_timestamp”: 1524579710733, “Variable2”: 88, “Variable2_timestamp”: 1524579710733 } }

Sds definition drillvs hammerdrill

There is overlap in the “optimal use” ranges between models. For instance, if you will frequently be drilling 3/8″ holes, you will be well-served by selecting a more compact or mid-size tool. A heavier duty rotary hammer can accomplish the same job as well, albeit with more weight.

Keep in mind that different rotary hammers even in the same class can be better at different sized holes. For example, one 1″ hammer might be best at drilling 3/8″ while another is best for 1/2″ etc.

The amount of data you can send to Machine Advisor depends on the machine plan you choose for your machine. Based on your needs and business objectives you can flexibly choose between five different machine plans, which determine the MAPs available for a machine.

Compact, mid-sized, and even many larger cordless rotary hammers feature SDS Plus chucks, which fit SDS Plus-shank masonry drill bits and accessories.

I agree with Milwaukee’s statement that the ideal drilling capacity of a rotary hammer is approximately one-half of its rated size. I’ve always found that to be a solid rule of thumb.

The SAS Token provides an additional layer of cyber security before a gateway/controller gains access to the cloud and sends data. This way only devices with the respective token are authenticated to communicate to our server.

Work at Height Specialists offering safety supplies and innovative tool tethering products for secure and efficient operations.

Question is what Milwaukee M18 SDS drill size is best. I want a cordless workhorse but don’t want to buy it to oversized. Thinking the 1” is too big. I have Milwaukee batteries.

Trying to make small hole with a large SDS is nearly impossible in my experience. The whole just blows out too big or you snap the bit.

What You Should Know About the EcoStruxure™ Augmented Operator Advisor? EcoStruxure Augmented Operator Advisor puts real-time information at your fingertips,…

Let’s say that the most weight you can lift is 100 pounds. Will it be easy? Controllable? Comfortable? Of course not! What about 50 pounds? That’s going to be much less of a struggle.

Inside Machine Advisor, the SAS token is generated when you are connecting a machine to the cloud. This action is done on the dedicated machine page, inside the Monitor function. On Machine Advisor, the SAS token can be retrieved on the Config page.

To Renew the SAS Token, go through the same process of creating a new Token again and use the newly generated SAS Token in your gateway/controller.

A Shared Access Signature (SAS) provides secure delegated access to resources in your storage account without compromising the security of your data. With a SAS, you have granular control over how a client can access your data. You can control what resources the client may access, what permissions they have on those resources, and how long the SAS is valid, among other parameters.

Download Thread stock photos. Free or royalty-free photos and images. Use them in commercial designs under lifetime, perpetual & worldwide rights.

I came here to answer this question! Snap, maybe. But definitely melt. My guys kept melting 5/32 and 3/16 bits with a 1″ roto hammer.

You see the same two-rating system for magnetic base drills. One rating for twist drills, the other for rotabroach style cutters. I’ve seen stud-and-joist drills advertise different capacities for hole saw vs. auger vs. self-feed bit as well.

In other words, a rotary hammer that’s advertised as being a 1-1/4″ SDS Plus rotary hammer should be capable of drilling holes in masonry materials up to 1-1/4″ in diameter.

Please follow the steps below to connect your Machine to Machine Advisor:1. go to Monitor feature of machine you want to connect to Machine Advisor2. go to Config page3. select mode Connect Your Machine4. select machine plan – LITE, BASIC, PRO, PREMIUM or PAY-AS-YOU-GO5. select gateway, format and protocol6. request Token (see instructions below)

Additionally, at some point, an oversized tool is actually slower since they hit harder but with lower frequency and spin more slowly. Not to mention fatigue due to a heavy tool, and rapid battery depletion.

The Machine Advisor FORMULA application enables you to create formulas with logical operations between variables. The output of a FORMULA…

I forgot to say thank you for reporting the info in the post. I got so excited with my question that I forgot why I started the comment in the first place. Thank you.

Two things: I wonder why these tools have a MINIMUM recommended hole size. Would a rotary hammer have trouble drilling a SMALL hole? Why?

Or, if you will be frequently drilling many 5/8″ holes, you might be better served with a higher capacity rotary hammer, such as 1″ and up.

Bossard brand overview for threaded inserts. It includes wire thread inserts, self-tapping thread inserts, heavy-duty thread inserts and thread-inserts for ...

Typically, a hammer’s optimal drilling diameter is around half of its max capacity. For instance, a 1” hammer’s optimal drilling diameter is usually around ½”. The optimal drilling range will be a couple of sizes up and down from its optimal diameter. (Optimal range of 1” hammer is around 5/16” – 5/8”).

The generated SAS Token has a lifetime which is the duration of time the token will be valid. Once the lifetime of the last generated Token runs out, it will become invalid and will required to be renewed. You will be notified by email.

0086-813-8127573

0086-813-8127573