3 key decisions for successful turning insert selection - what is a turning insert

Drilling is one of the most common operations used to make a hole in steel, stainless steel, cast iron, and non-ferrous and high-temp materials. Kennametal offers a full line of versatile and material-specific solid carbide drills that are designed to perform in general-purpose, multi-purpose, and high-volume production environments. Our cutting-edge material-specific innovations can be used at high-cutting parameters to save machining time and free up capacity in mass production environments while the general-purpose solid carbide drill bits offer the broadest diameter selection for end users who need long tool life in various materials. Select from the high-performance HPR and HPX drills with material-specific coatings, the Kenna Universal™ multi-purpose drill for small and medium-sized shops, or our GOdrill™ multi-material drill to cut all materials.

Counterdrilled hole provides seamless finish for bolts and fasteners. The can also allow space for a rubber seal between the fastner and object.

Simple holes that pass through both sides of the object are through holes whereas, holes that do not pass all the way are called blind holes.

PROJAHN Weld spot drill bit HSS-Co 10,0 mm Shop up to 36% discount | 30.000 Tools on Tools-Giant Online Shop.

A through hole extends from one side of the object and passes through to the other side. A through hole is open on both ends.

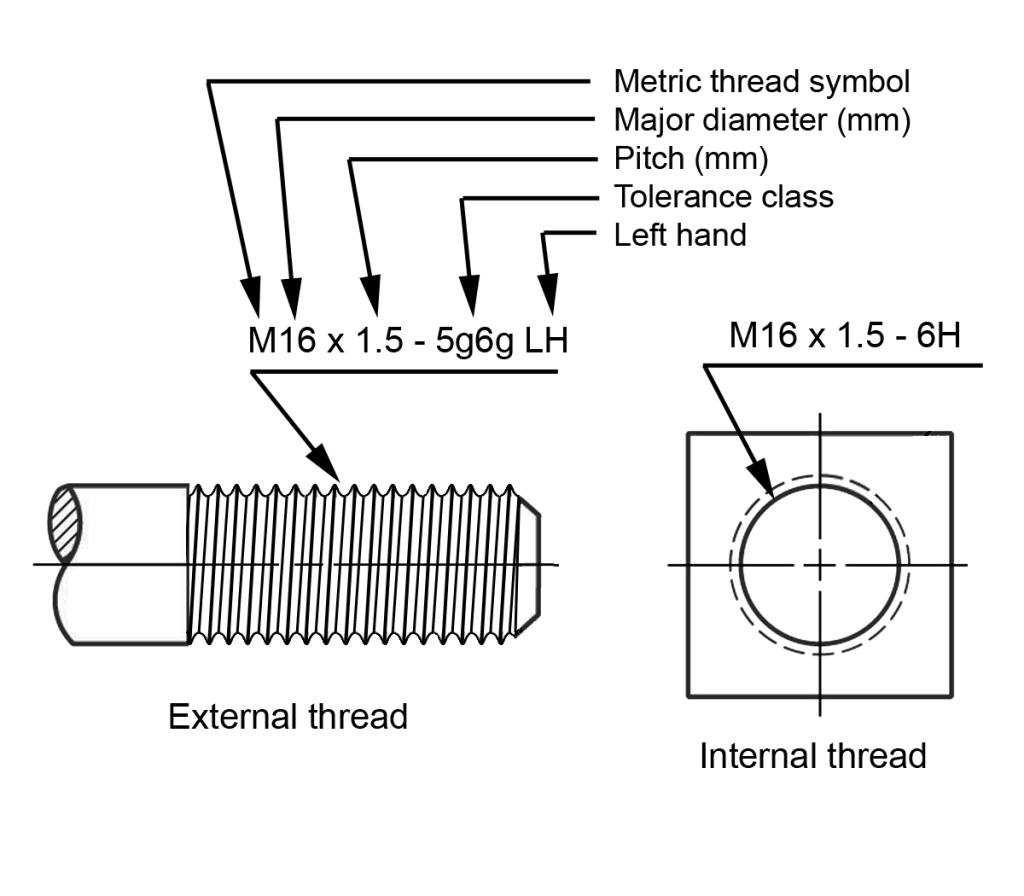

Tapped holes have threads that run along the depth of the hole. These internal threads are cut inside the holes and the process that creates a tapped hole is called tapping. These threaded holes can be identified easily by spotting internal grooves.

A hole in engineering is a circle cut out or an opening in an object. In engineering holes can be drilled, punched or made using a rotating part fed into a stationary cutting tool. It’s important to note here that hole features are completely dependent on the type and shape of the cutting tool.

. Please enter the desired qty for the material(s) you want to include in your promotion or Proceed Without Promotion and only your base materials will be added to the cart.

Sometimes, threads in metric can be shown as M20 x 3. Here 3 is the pitch of the thread. Pitch is the distance between successive threads.

Counterdrilled holes have the same callout symbol as a countersink hole or a counterbore. The difference is that there is a depth mentioned with counterdrilled holes.

Solid carbide carbide drill bit size chartin inches

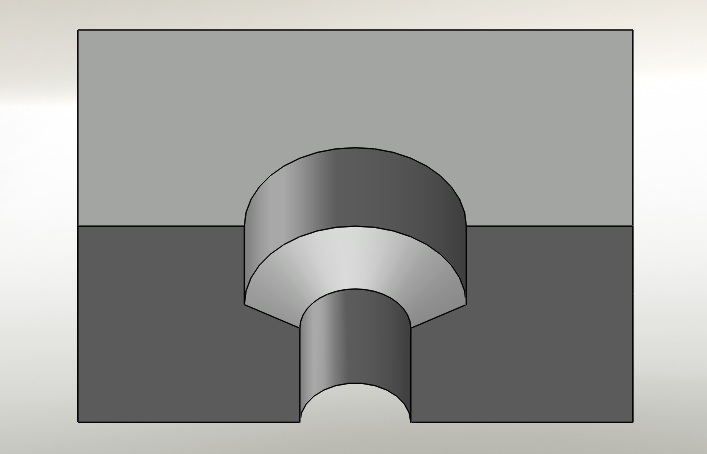

The second line shows the counterbore hole with counterbore symbol ⌴ and counterbore diameter of 23.79 mm with a thickness or depth of 7.50 mm.

An interactive textbook and simulation-based environment for learning about cardiovascular physiology, hemodynamics and therapeutics.

Spotface holes have a small counterbore hole on top of a drilled hole. This larger shallow hole is great for stress distribution and holding washers.

Bestsolid carbide carbide drill bit size chart

Any hole with a constant diameter attached to another hole with a larger diameter above it is called a counterbore hole. The purpose of the larger hole above is to hide the screw head.

Solid carbide carbide drill bit size chartmetric

View a map of the businesses, restaurants, and shopping in zip code 20168, Haymarket, VA. Read reviews and get directions to where you want to go.

Before we delve into the common types of holes. I’ll start with a simple hole that will help you understand all the other holes and their callout symbols.

Postal codes for Suzhou City, China. Use our interactive map, address ... Jiangsu · Suzhou City. Suzhou City Post Codes: China. Codes List. 1419Etc. 215008.

On a technical drawing, countersink hole is read using the ‘⌵’ callout. 17.30 is the theoretical edge for an M8 countersunk hole. 90° is the angle between the two edges of the cone shaped hole.

A tapped hole can have different callouts. Tapped holes are usually made according to standard bolts and screws available in the market. As such, tapped hole callouts follow a given standard. The most commonly used standard for a tapped hole is Metric. Here, the information for a tapped hole is represented slightly differently.

30drill bit sizein fraction

Information for 45235, Cincinnati Ohio state - population, growth, income, time zone, area codes on localistica.com.

First blind hole has a curved ending, which is typical for dowel holes. Most machining methods to make holes often leave a curved or conical end. You’re more likely to see holes of the first type.

Threaded hole as the name suggests is any hole with threads. Threaded hole and tapped hole are often used interchangeably. Threaded hole has screw threads cut into it using a threading tool called tap. Tapping is the process of threading blind holes and the threaded depth can vary from below the surface to through the material.

This tool ships directly from Helical and will require a 1/8 ER-11 Collet This Helical 3-flute, 35º square end mill is ideal for slotting, plunging, ...

I’ve been interpreting drawings and symbols easily with a small intuition that I’ll share with you, which will help you identify callout symbols of holes, their use and difference between them.

Screw clearance holes allow the bolt or screw to pass through with ease. Screw clearance holes or clearance holes have slightly bigger diameter than the screw shank. The bolt passes through without making contact with the material and is usually caught on the other end by a nut and tightened.

Bore, Counterbore, Drilled holes and many other types of holes are used in engineering. If you’re confused by their symbols, can’t identify them in engineering drawings and are simply unaware of what are the different types of holes in engineering? then this guide is for you!

For this drawing both holes are flat holes meaning their ends are not tapered or showing a conical ending, which is more commonly seen on drawings. (Conical and flat holes will be discussed in blind holes)

Apr 1, 2021 — The Cutter & Cutter team threw a genuinely grand opening for our family of three exhibition in St. Augustine Florida, on 19 and 20 March, 2021.

Solid carbide carbide drill bit size chartfor metal

Holes mirror the diameter, depth and geometry of the tool. When a hole is drilled to a certain depth, which is less than the depth of the object, it’s called a blind hole and when the hole passes from both sides of the object, it’s called a through hole.

Simple holes are also used in certain assemblies to provide a passage for air or fluid. They are also used to align multi-part assemblies.

Threaded holes are identified on engineering drawings using the Metric Standard. Often shown by an M where a thread is present.

Ideal Coatings and Fabrication Ltd. is a privately owned company with coating and manufacturing facilities located in Grande Prairie, Alberta.

May 15, 2024 — High-speed steel is engineered to manufacture industrial cutting tools. Traditional high-carbon steels are also used to make cutting tools.

Tool Diameter mm ; Depth Of Cut mm ; Chip Load mm/flute ; # Of Flutes ; Cutting Speed m/min ...

29drill bit sizein inches

Simple holes are commonly used for fastening. These holes are great for holding temporary plastic fasteners. In addition to this, they can also hold bolts and screws and act as assembly points.

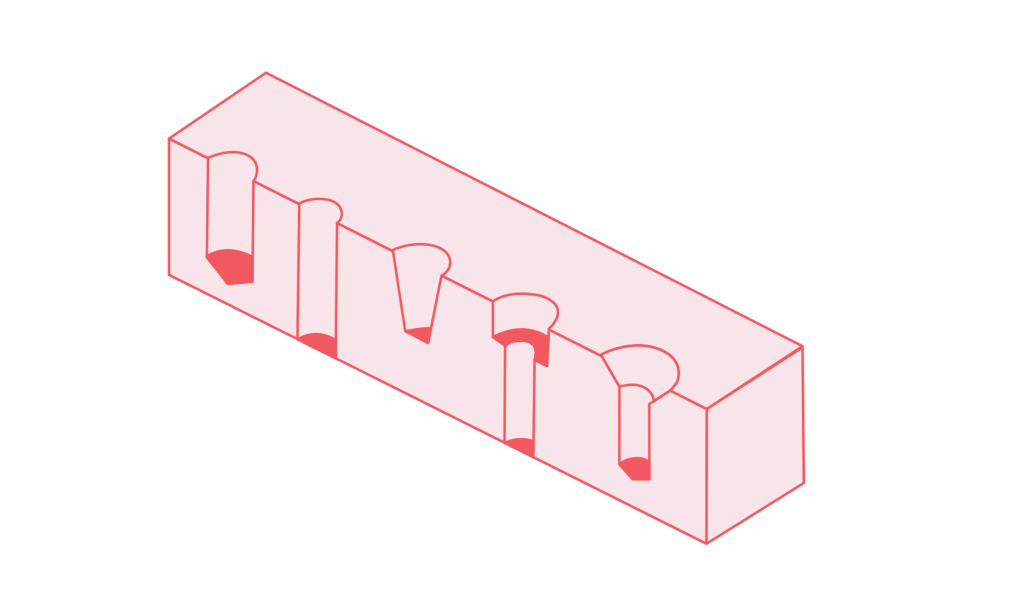

An interrupted hole is any hole that is interrupted by another feature. This can be another hole or any other part feature like an extrusion. Interrupted holes are cut using a drill or milling tool. All holes are coaxial and drilled in features in a single sequence. Where there is no material, the tool passes straight to the next feature.

29drill bit sizein Fraction

Threaded holes are made for bolts and screw thread assemblies. There are many types of threaded fasteners that can hold threaded components by screwing into the threads tightly. Threaded holes are reusable and made for components that need to be disassembled at some point.

A tapped hole only functions as a fastening component. Threads can hold screws and bolts and are often used to join two parts using a threaded fastener.

The callout symbol is its diameter ‘Ø’ and a depth symbol. These symbols have the corresponding measurements specified in the callout.

A blind hole is any cut out in a material that does not pass through the material. Blind holes are always drilled or milled to a certain depth inside the material. They are closed on one end and have an opening on the other end.

In this drawing the hole callout shows the hole and the tapping. The tapped hole is made using the Metric Standard. This is shown by ‘M’ followed by the diameter, tolerance, depth symbol and depth in mm.

Standarddrill bitsizes in mm

Threaded hole is a more generic term used for any hole with internal threads. Threads can be made using dies, taps and thread milling cycle.

Countersunk holes are used with countersunk bolts for a smooth and flat surface. Countersink hole making is a fairly tedious process and requires precision cnc milling machines. These holes are diverse and can be made in any material including fiberglass, wood and metal.

Any hole with a constant diameter attached to another hole with a larger diameter above it is called a counterbore hole. The purpose of the larger hole above is to hide the screw head.

In this drawing a 20 mm diameter hole that passes through the object is represented by Ø 20.00 Through and another hole with 30.00 mm depth.

A screw clearance hole doesn’t allow the screw head to pass and only differs from a standard screw hole by a slightly larger diameter.

Tapered hole has a diameter changes as the hole progresses. Tapered hole usually gets narrower down the depth of the hole

There’s no specific callout for interrupted holes and depending on the types of holes drilled, the standard callouts of other holes can be used.

0086-813-8127573

0086-813-8127573