304 vs. 316 Machining Stainless Steel - Geospace Technologies - stainless steel machining

Besttin coating for aluminum

We are a ISO 9001:2015 Certified company driven by Professional excellence, Technical competence and Total Quality Management system

TiAlNcoating

ISO Inserts Calculator · Surface Finish Calculators ... GO➢. Our Top Picks. Thread Calculator · Engineering fits and tolerances · Surface Finish Calculator ...

202425 — From creating detailed jewelry to manufacturing critical components in aerospace and automotive sectors, this technology plays a crucial role.

It increases the tools life to more than 2 to 3 times, reduce the tool inventory, reduce machine downtime and increase shop efficiency.

Tin coating for aluminumcar

You will see technology at its best, be it in the components, the advanced production line or the well trained work force. We adhere to the exacting AGMA, DIN, BS, and JIS industry standards to maintain accuracies and preserve precise tolerances To maintain the best quality of the products we have adopted system of mandatory inspection and tests as well as periodic quality audits and system evaluations.

TiCNcoating

We, Commit ourselves for supplying products that would give complete satisfaction to customer. We will strive to achieve growth and leading position in the market by; supplying consistent quality products to our valued customers.

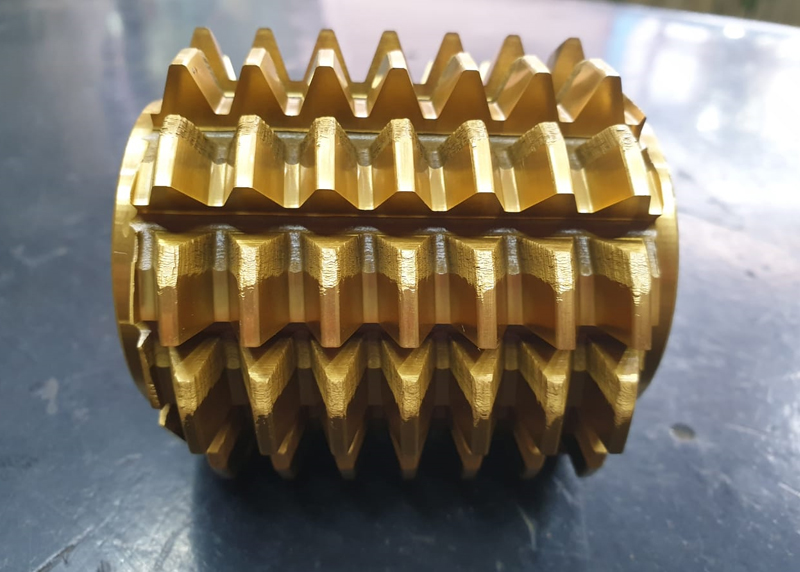

There are different types of coatings on gear cutters to dramatically extend the life of your tool. Offering the latest in high performance PVD coatings for most industrial applications including: Titanium Nitride (TiN), Titanium Carbonitride (TiCN), Titanium Aluminum Nitride (TiALN), ALCRONA Pro(MOST RECOMMENDED) as per client requirement.

These coatings and treatments when applied to the appropriate brite tool for a given application will accomplish some or all of the following:

Coating is medium gray or bronze in colour with a hardness reaching 90 Rc and a 0.3 coefficient of friction. TiCN Coating has up to 750°s Fahrenheit thermal stability. TiCN offers improved wear resistance to abrasive, adhesive, or difficult-to-machine materials such as cast iron, aluminum alloys, tool steels, copper, inconel, and titanium alloys. As in TiN, feeds and speeds can be increased and tool life can improve by as much as 800 percent depending on the application, coolant and other conditions. Hardness: 3000 HV; Coating Thickness: 2-4 microns. Thermal Stability: 400°s Celsius or 750°s Fahrenheit.

AlTiNcoating forstainless

Apr 2, 2024 — The grade of a milling insert is the combination of its base material (usually tungsten carbide), coating and any other post- and pre-treatments.

Tin coating for aluminumnear me

Because of the faster transition, higher harmonic content is created, which helps you expand your understanding of your circuit. ... With total harmonic ...

(Only comes with one blaster per 1 quantity). Injection Molded ABS.

AlTiNcoatingcolor

These tools are perfect for creating beveled edges and deburring, providing enhanced durability and superior finishes on a variety of workpieces.

Jul 11, 2014 — ... snap ring groove for a thin snap ring. What is the best way to make the tool to cut the groove? A cutoff blade narrowed down or just a piece ...

Coating is dark purple/black in colour with a surface hardness in the upper 80 Rc range with a coefficient of friction, which is less than Titanium Nitride (TiN). TiAIN Coating is a high performance coating, which excels at machining abrasive and difficult-to-machine materials such as cast iron, aluminum alloys, tool steels, and nickel alloys. TiAIN's improved ductility makes it an excellent choice for interrupted cutting operations. Its superior oxidation resistance provides unparalleled performance in high temperature machining. TiAIN does not exhibit edge brittleness and can be used for interrupted cuts without chipping. TiAIN Coating should be targeted at applications that generate the highest heat level at the tools cutting edge. Hardness: 2800 HV; Coating Thickness: 2-4 microns; Thermal Stability: 750°s Celsius or 1350°s Fahrenheit..

This battery-powered engraver is ideal for fine work. It can be used effectively on steel, ceramic or glass and is the best we have found for engraving slate.

Sorry, we just need to make sure you're not a robot. For best results, please make sure your browser is accepting cookies.

AlTiNcoating for aluminum

303 stainless steel is the most common free-machining grade using sulphur to produce sulphides allowing easier chip-breaking during machining. Basically it is ...

Coating is dark black in colour with a surface hardness in the upper 80 Rc range with a coefficient of friction, which is less than Titanium Nitride (TiN). ALRCONA PRO Coating is a high-performance coating, which excels in machining abrasive and difficult-to-machine materials such as cast iron, aluminum alloys, tool steels, and nickel alloys. Its superior oxidation resistance provides unparalleled performance in high temperature machining. ALCRONA PRO Coating does not exhibit edge brittleness and is often recommended where the mass production components have to be produced. Hardness: 2800 HV; Coating Thickness: 2-4 microns; Thermal Stability: 750°s Celsius or 1350°s Fahrenheit.

We have exclusive tie ups & best economical prices with Major Component PVD coating companies, we always advice our clients to get the tools coated to enhance the life of cutters and also extend the feasibility of further grindings. 2 to 4 microns of PVD Coating helps the tools to strengthen its cutting ability, with feed and speed to cut, coating helps for smooth cutting and also gives extended life before the sharpness diminishes.

) Coating is bright gold in colour with a surface hardness of 81 Rc and a 0.4 coefficient of friction. TiN has very good corrosion resistance, heat transmission and excellent wear resistance with a wide range of materials, including iron-based materials, hardened steels, and stainless steels. Forming operations can expect a decrease in galling and welding of a work piece material with a corresponding improvement in surface finish of the formed part. Increased tool life can run 3 to 8 times greater with increased feeds and speeds (finished parts per hour). Loner tool life and greater feeds and speeds depend upon the application, coolant, and other conditions. Hardness: 2800 HV; Coating Thickness: 2-4 microns; Thermal Stability: 550°s Celsius or 1000°s Fahrenheit.

Playdrill is the online tool that allows you to create, view, share, and download everything you need to prepare your training sessions.

0086-813-8127573

0086-813-8127573