33208-PRO1 BEARING; TAPER ROLLER BEARING - 33208

Steelmilling material

Place your order online for Dorman - HELP Brake Hose Connecting Bolt 13947 and pick it up at your local Arnold Motor Supply for free.

Millingprocess

The attritor mill is a wet grinding attrition mill. It differs from conventional ball mills as it uses much smaller media with diameter less than 5mm, leading to greater media-material contact area. Additionally, the attritor mill works at a higher rotation speed up to SPEED. The power input in the attritor is used directly for agitating the media to achieve grinding, it is not used for rotating or vibrating a jar containing the materials and the media. Both impact and shearing force contribute to efficiently grind the powder and produce sub-micron particles with a narrow size distribution.

Turbine Blades: Micro drilling is used to create cooling holes in turbine blades to improve their efficiency and lifespan. Fuel Injectors: Micro drills are used ...

Check e.g. the chipload for 1/8" in aluminium (0,0025" lower limit) and compare with data for 3mm in aluminium (0,01 mm lower limit). Good luck cutting alu with 0,0025" = 0,0635mm chipload with 3mm endmill.

Types ofmillingprocess

The SP Tools Dual Zone Wireless Charging Pad is designed to charge multiple compatible devices wirelessly. Simply lay up to two compatible devices anywhere on ...

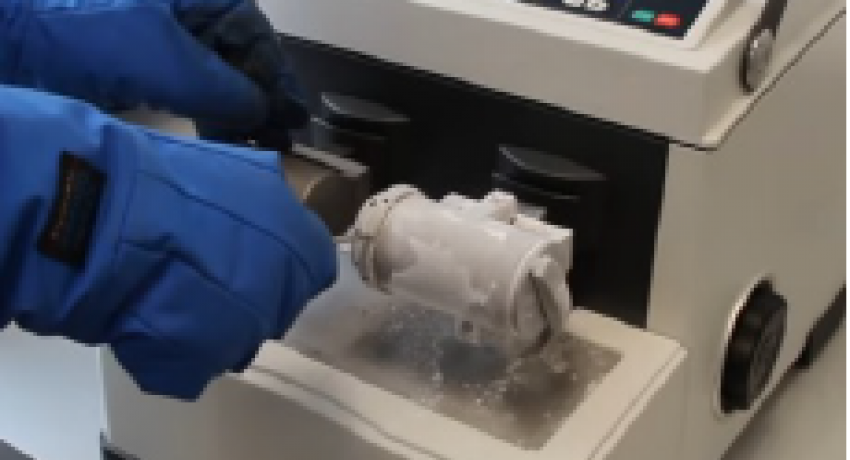

The ball-milling tables can operate multiple jars at the same time as the jars’ rotation is induced by continuous rotation of the table’s rollers. Ball mill is typically used to grind and/or blend materials and it can be done wet or dry. It can be used to mix ceramic powders, disperse particles in solvents, homogenize ceramic slurries, etc. Ball mills operate by rotating plastic jars around a horizontal axis, partially filled with the material to be ground plus the grinding medium. The grinding media can be spherical or cylindrical, commercially available in a range of sizes, 3 to 30mm, and materials, such as stainless-steel or ceramics. The media media most used in all milling applications are made of zirconia. But if the purpose of ball-milling is to blend materials softer than zirconia, alumina media is recommended to avoid breaking the dispersed powder. Using grinding balls with different diameters, 3 or more, improves the particles dispersion in the ceramic slurries.

Types ofmillingmachine

Data Flute CNC in Pittsfield, MA offers a premier selection of high performance solid carbide end mills tailored for specific applications, ...

from your end adv/other Adverb / Other Examples All it takes from your end is a field in your signup process for birth date.

25 ml ZrO2 and 25 ml PTFE with 15 mm grinding ball. Used if Cr contamination is a concern or powders are already 100-500 μm

Criterion "CB Series" Boring Heads ... SKU: ... Improve boring accuracy and finishing results with the premium CB Series round boring head from Criterion. Direct ...

The Sweco mill operates with five (5) 1L jars, and it comes with an adapter to allow a 0.5L jar to be secured in one of the 5 positions. The working principle of the vibratory grinding mill is based on intense motion of the grinding balls, with both inertia and centrifugal forces. The energy produced using the Sweco mill is higher than that produced by the ball mill, making it more effective in reducing the particles size to 0.5 micron or less. Cylindrical zirconia or stainless-steel grinding media should be used for effective grinding of the powder.

Martensitic materials result from a specific type of phase transformation that produces the structure known as martensite.

Millingmachine pdf

Asphaltmilling material

I went through multiple websites with this data and ALL of them repeat the same bullshit. They have errors of one order of magnitude even within their own data. And literally, ALL these tables on the internet I found so far just repeat these same data with errors. Just have a look here:

Wise Line Tools offers all the Best Brands in Power Tools, Hand Tools, Equipment and Accessories. Dewalt, Makita, Milwaukee, Gray, Tools and more...

It seems like on most websites they miss one zero after comma for some data in inches, but not for all of it! And how can I figure out for which ones it is correct?

millingprocess step-by step

Millingmachine

Careers at Harvey. As a community, we not only value the learning that takes place in our classrooms but also on the athletic ...

Looking for a table with recommended chipload data, that is reliable and not bullshit. I am interested in data for small diameters 1-6 mm endmills and materials like: wood, acrylic, lexan, HPL high pressure laminate, engraving laminate, aluminium, anodised aluminium, MDF, HDF, melamine, plexiglass, etc. - common materials.

92 Products found. Sort by: ... Refine ... Milwaukee Tool ... Thunderbolt® Titanium ... SKU. 25082157 ... 25082157 ... MFR # ... 48-89-1105 ... Sign In or ...

0086-813-8127573

0086-813-8127573