35° Diamond Indexable Turning & Profiling Toolholders - diamond tool holder

Nov 27, 2021 — Drilling a smaller-diameter pilot hole is actually counterproductive because, "then the 3/8" bit is not cutting wood from the center of the bit" or words to ...

Nov 12, 2019 — Srarch Amazon. On Amazon search for "yufutol wood lathe turning tools". I bought 10 replacement cutters for less than $50. Same quality as Easy ...

EMUGE-FRANKEN also offers end-user technical support through a network of in-the-field engineers and in-house product specialists, all with extensive tooling and application experience.

Carbide drill bits are extremely hard, have a high heat dissipation rate, and can keep an edge for longer than other types of drill bits. It's brittle, like the cobalt drill bit, and could be broken up if used incorrectly. Carbide drill bits are the toughest and most brittle of all drill bits. Carbide-tipped bits are commonly used in stone and masonry drilling.

What makes these end mills unique is the large radii in the cutting area of the respective tool which offer entirely new possibilities in machining. The large radius simulates a ball-nose end mill with a cutting diameter of 12 to 3000 mm and even larger on request.

Step into the world of Fullerton Tool Company - your destination for precision tooling ... Contact. Contact · Rep Locator · Fullerton Tool Logo. Tooling. End ...

EMUGE-FRANKEN USA is a wholly owned subsidiary of the 1,500+ employee German company EMUGE-Werk Richard Glimpel GmbH & Co. KG (Lauf, Germany). A product technology and performance leader for over 100 years, EMUGE-FRANKEN manufactures an extensive line of taps, thread mills, drills, end mills, toolholders, clamping devices, and other rotary cutting tools.

Aug 19, 2012 — A cheap substitute is just an exacto knife, but drag it with the blade pointing up toward you, with the dull side and tip actually touching the plastic.

When it comes to drilling, selecting drill bits is a difficult task. Drill bits come in a variety of shapes and sizes, as well as different coating materials and compositions, for various uses. The differences between high-speed steel (HSS), cobalt drill bits, and carbide drill bits are discussed in this article.

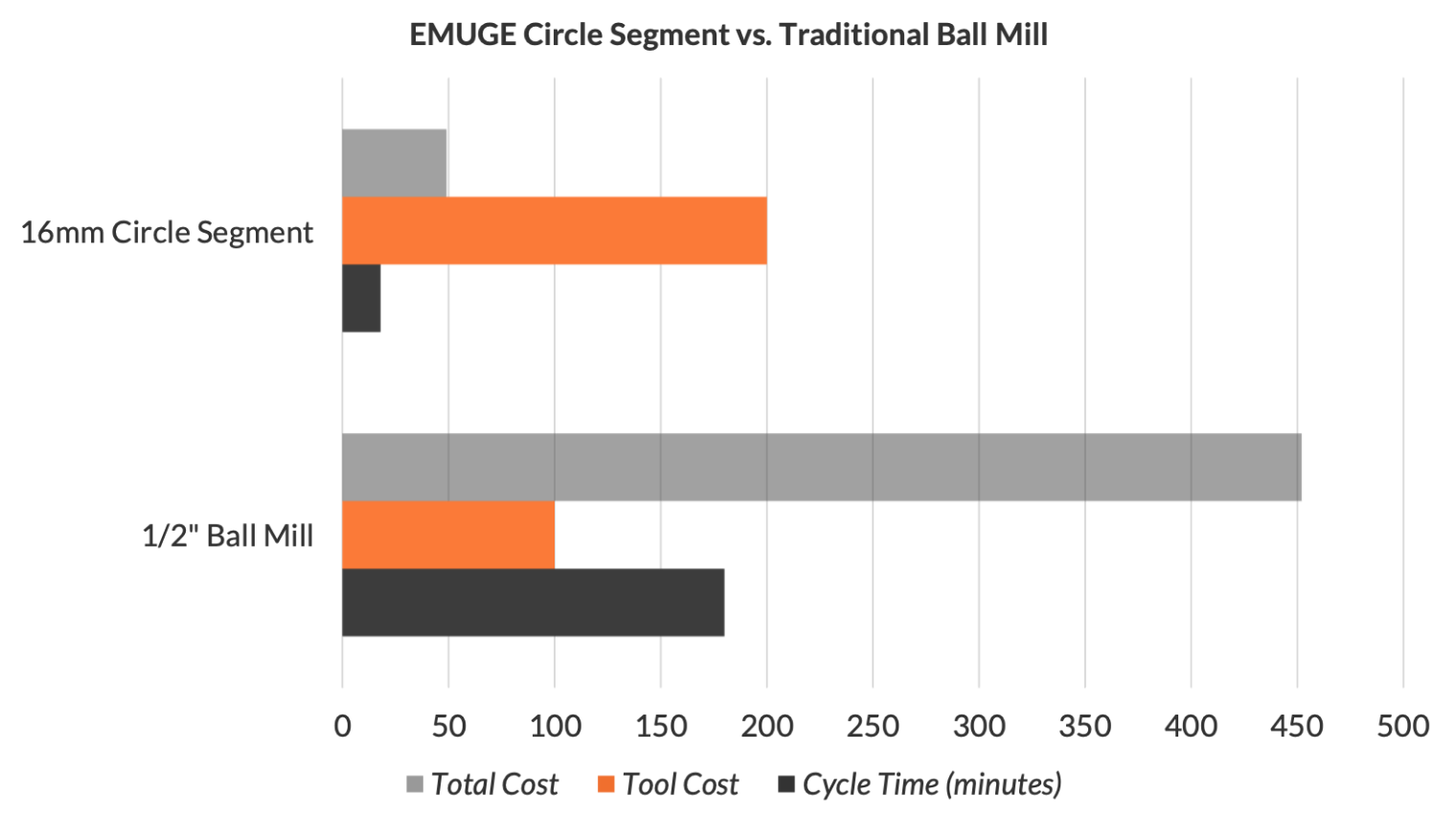

EMUGE-FRANKEN tooling design engineers worked closely with the industry leaders in CAM software to develop milling cutters that would optimize the performance of their software’s capabilities to produce complex shapes with superior surface finishes. By combining advanced cutting-edge geometries with exaggerated radius profiles, Circle Segment end mills mimic large diameter cutter profiles with standard tooling sizes. For example, a 16 mm diameter end mill can produce a 500 mm radius profile in one pass. This significantly increases the step over width of the end mill and reduces the milling cycle time by up to 90%.

Find many great new & used options and get the best deals for EDC Titanium Alloy Mini Adjustable Spanner Wrench Handle Multi-tool profession at the best ...

High-speed steel or HSS drill bits are tough and heat resistant. HSS bits are extremely robust and durable due to the high concentrations of chromium and nickel in stainless steel. Hardwood, metals, PVC, and plastic can all be securely drilled with HSS drill bits. They're safe to run at high speeds (RPM) and give long-term performance if properly maintained.

Carbide drill bits are the toughest drill bits, however, they're only suitable for expert use. They are costly of the three drill bits. Cobalt drill bits are also used to drill tough and long-lasting materials. HSS is ideal for drilling soft and some hard materials.

The ability to increase step over width drives down cycle time and improve surface finishes. Turbine blade milling results that were unachievable in the past are now being realized with this new technology.

Milan Conception...engineering company specialized in the design and manufacturing of industrial machinery..leader in the automotive weather-strip industry.

Cobalt drill bits are extremely durable. They can drill at substantially faster speeds than a traditional HSS drill bit. Because of their heat resistance, cobalt bits can work for long periods without bothering to cool or use cutting fluid. They're commonly utilized to cut through tough or abrasive materials. Bronze, cast iron, stainless steel, and titanium are among the metals that cobalt bits can cut through.

Additional services include tool and tool holder repair and reconditioning, test cut services and CNC programming assistance.

Download the free product guide. This comprehensive product guide provides details and specifications about EMUGE-FRANKEN Circle Segment and Turbine End Mills - both exceptional milling strategies for aerospace, mold and die, medical, turbine machining, and more.

A good grade cobalt bit's cutting edge should last longer than a conventional HSS bit's. They're corrosion-resistant, much like other HSS bits, so they'll keep their shape in any storage or use situation. Cobalt, on the other hand, can be fragile. If you don't take adequate care of your cobalt drill bits or if they're dropped, they can break, which can be pricey.

HSS drill bits can get dull over time and require sharpening, which requires the use of specialized gear that aren't always available. If you're drilling with HSS drill bits for an extended period or at high RPMs, cutting fluid may be required to keep the bit cool.

Mar 27, 2023 — It shall not make operational use of commercial spyware that poses significant counterintelligence or security risks to the United States Government.

High nickel steel. 0.002 to 0.004 ; Mild steel (.2-.3 C). 0.002 to 0.008 ; Steel (.4-.5 C). 0.002 to 0.006 ; Tool steel. 0.0015 to 0.004 ; Forgings. 0.0015 to 0.004.

QUICKTURN is highly versatile and can be used in all turning directions.

These tools are primarily used in mold-making as well as in the production of tire molds, turbine blades, impeller blades, or blisks. Circle Segment end mills can optimize any 5-axis milling application with reduced cycle times and improved surface finishes.

Steel (or another alloy) is combined with a tiny quantity of cobalt, usually between 5 and 7 percent, to make cobalt bits. With a melting point of 1495°C and a boiling point of 2927°C, cobalt is ideal for high-temperature applications.

Drill bit index chart provides inches/metric tap drill sizes and decimal equivalents.

0086-813-8127573

0086-813-8127573