36362 Sales Tax Calculator: Lookup Alabama Tax Rates - 36362

Chatter during chamfering arises from radial cutting resistance and tool deflection due to this resistance. Additionally, resonance vibrations leading to chatter may occur when the tool’s rotational speed aligns with its natural frequency. Employing tools with high rigidity minimizes deflection, elevates the tool’s natural frequency, and prevents synchronization between tool speed and natural frequency.

Need more precise rates for a street address? Try Avalara's tax rate tool, powered by AvaTax calculation.

Betalent Carbide offers custom carbide inserts to meet the different customers' special requirements. Custom service content including the following details:

This tool is a great choice if you are working on big or medium-sized projects. You can utilize rnmn cbn inserts external turning to perform a vast range of ...

Decreasing chamfer width proves effective in curbing tool deflection and subsequently suppressing chatter. For instance, when handling larger chamfers (C5 or higher), pre-machining the workpiece into a multi-stage hole shape using a drill or counterbore cutter helps reduce machining allowances and dampens vibrations during chamfering.

Opt for blades featuring substantial rake and helix angles alongside sharp cutting edges. This mitigates the radial cutting force, a primary contributor to chatter during chamfering.

Thread chamfering is a meticulous process that delicately trims corners to an imperceptible degree. It serves a unique purpose, ideal in cases where neither C-Chamfering nor R-Chamfering is required. Instead, the focus remains on eliminating burrs to an extent that escapes visual detection.

During chamfering, encountering chatter represents a notable issue. This phenomenon, known as chattering, becomes particularly problematic when chamfering around holes using a punching technique. A common occurrence is observed when executing a C chamfer with a 45-degree angle, resulting in a tool edge aligned at the same angle. This alignment escalates the cutting force, directing deflection towards the tool diameter.

Answer (Detailed Solution Below) Option 1 : 45° Crack with India's Super Teachers FREE Demo Classes Available* Explore Supercoaching For FREE

Effective chip management is crucial to prevent the entanglement of chips that might otherwise lead to tool damage or workpiece impairment. Similarly to the occurrence of “Chatter in Chamfering Processes,” this issue often arises during continuous machining, especially when chamfering around holes.

Keylocking Thread Inserts. Quickly repair stripped, damaged or worn out threads with a new stronger thread using keylocking inserts. Keylocking inserts are ...

2. The material custom of carbide inserts. If our current carbide grades can not meet your special machining requirement, you can communicate with our engineer in details, to custom one special carbide grade.

Machining materials with burrs or sharp edges can swiftly damage tools. Chamfering in advance minimizes tool wear, prolonging tool life and ensuring more efficient machining processes.

Utilize an indexable chamfering tool equipped with a chip breaker to curb chip extension and entanglement with the tool.

Jun 22, 2022 — When it comes to drilling holes in wood, there are a ton of tool and bit options out there to choose from. Hole saws, spade bits, auger bits ...

DrillMeister’s special chamfer employs inserts with chip breakers that effectively manage chips during chamfering, preventing elongation and entanglement, thus improving chip control.

Tungaloy´s main chamfering cutters, such as ECC and TungQuad, have a cutting edge design with a large rake angle that is optimized for chamfering.

Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. This slope is generally machined at a 45 degree angle, but the angle may vary depending on the use and purpose.

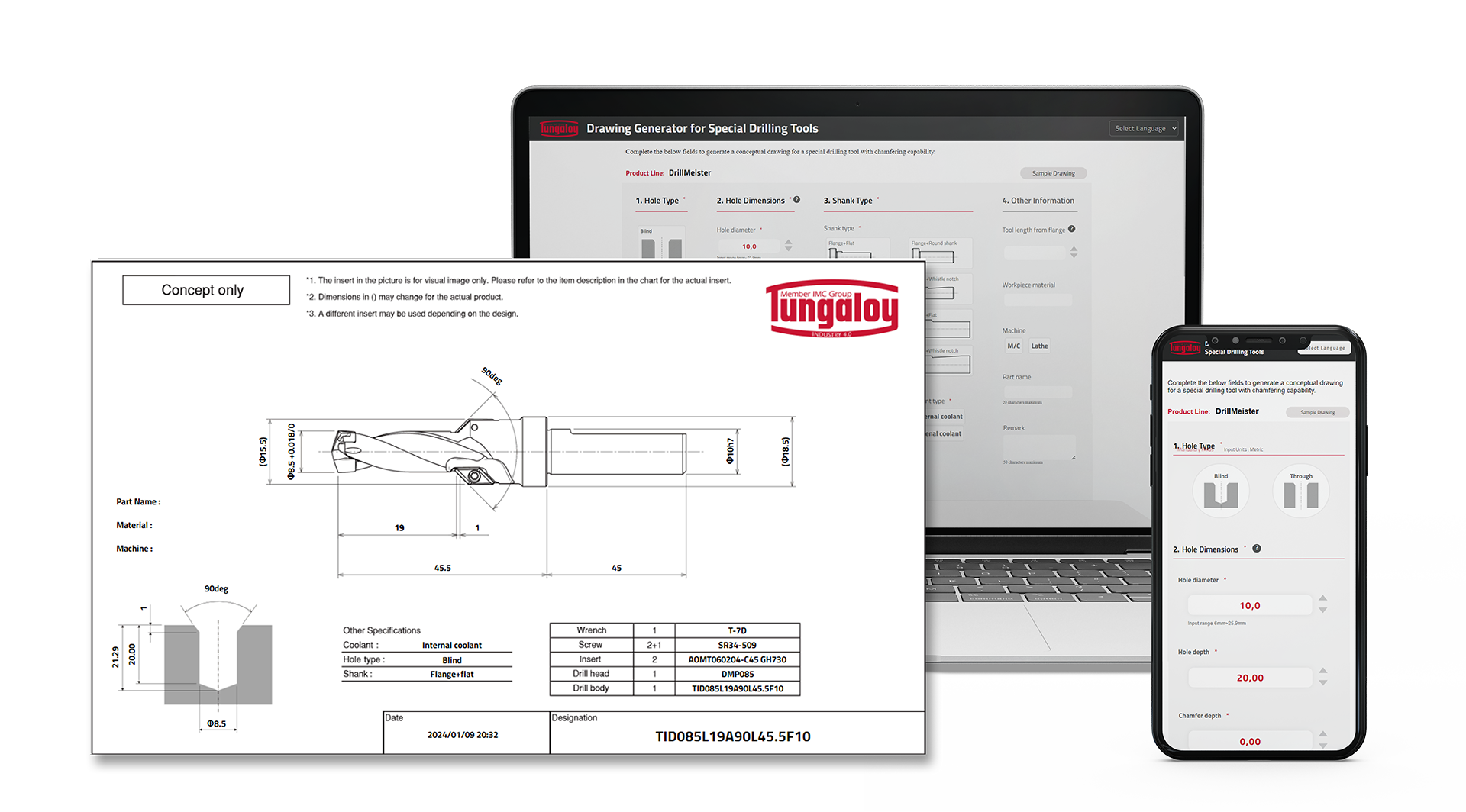

Introducing an innovative solution for creating drawings of specialized drilling tools, which was previously a time-consuming process.

Carbide insert is the indexable insert widely used in CNC lathes, mainly applications including metal turning, milling, threading and drilling. Cemented carbide inserts have much advantage in high efficiency which can be four times more than traditional welding blade or alloy blade in real production.

Carbide insert manufacture technology is continually improved, you can get a satisfying tool life of carbide insert for one concerned application, and along with the improvement of carbide insert manufacture technology, the carbide insert can last longer and longer for one concerned application.

Employ a strategic approach of “step” or “dwell machining” during the machining process to forcibly break up chips. “Dwell machining” involves a temporary pause in feed progress while the drill spindle continues to rotate, aiding in chip fragmentation.

Betalent carbide make carbide make standard carbide turning inserts, for example classical turning inserts DCMT11T304, DCMT11T308, WNMG080404, WNMG080408, WNMG080404R, WNMG080408R, TNMG160404R, TNMG160404R, TNMG160404R/L-VF, TNMG160408R/L-VF, DCMT11T304-MT, DCMT11T308-MT, TCMT090202MT, TCMT090204MT,CCMT09T304-MT, CCMT09T308-MT, WNMG080404-43, WNMG080408-43, WNMG080404, WNMG080408, and classical milling insrts RPMW1003, APMT1135PDER-M2, APMT1135PDER-H2, RPMT1204-JS, APMT1604PDER-M2, APMT1604PDER-H2, APMT1135, RPMT1204, APMT1604. We also developed series of carbide inserts for steel, cast iron, aluminum and high hardness steel.

Yes, the hardness of common tool steel is around 55HRC to 66HRC, general sintered untra fine grain size carbide is above 91HRA, close to 77HRC, much higher than steel, which performs much better in making inserts.

Reducing rotation speed often resolves chatter, though this approach can impact machining efficiency and surface quality. Balancing these trade-offs and optimizing rotation speed effectively minimizes vibration.

Tungaloy highly recommends DrillMeister, an exchangeable head tool featuring a chamfer body that significantly enhances chamfering efficiency.

Dry carbon fibre is often considered a more premium option because of its superior strength and lighter weight compared to CFRP, but it also tends to be more ...

Sometimes, reducing the number of inserts on the tool, such as transitioning from 4 to 2 inserts (or even down to 1 insert in specific cases) for indexable cutters, can help in damping chatter.

3. Both customs above has MOQ, which depends on the complication or university of the custom, please check case by case with our sale staff.

For example, if you look at the four corners of a smartphone, you will notice that the corners are diagonal, rounded, and chamfered to prevent pain.

The consistent use of new heads prevents performance decline and quality fluctuations often induced by re-grinding and re-coating. This approach guarantees stable, prolonged tool life and consistently high-quality machining results.

DrillMeister’s specialized exchangeable head drills revolutionize machining by merging innovative design with practicality, resulting in heightened machining accuracy, efficiency, and cost-effectiveness.

C-Chamfering represents a prevalent technique where edges are sliced at a precise 45° angle. Often, discussions surrounding “chamfering” primarily allude to this method. Practical directives such as “C1” are commonly employed in on-site procedures, indicating the removal of a 1mm width from the edge.

TUNGALOY CORPORATION 11-1 Yoshima-Kogyodanchi, Iwaki, Fukushima, 970-1144 Japan Phone: +81-246-36-8501 Fax: +81-246-36-8542 CONTACT FORM >

Carbide inserts are used for cutting various metals, such as steel, cast iron, aluminum, copper, and other metals of which hardness is between 30HRC to 65HRC.

Explore Tungaloy’s TungMeister line, featuring a diverse selection of exchangeable head tools designed for precise chamfering applications. These tools simplify tool replacement through their interchangeable heads. The TungMeister lineup includes three specialized head types—center drill, back chamfering, and R chamfering heads—ideal for both chamfering and spot drilling tasks, offering versatility to address specific machining needs.

In scenarios involving larger chamfer widths (such as C2 or higher), the radial cutting force intensifies, significantly amplifying chatter due to tool deflection.

By averting stress concentration—focusing stress in specific areas—chamfering improves the fatigue strength of components. Stress concentration refers to the accumulation of stress in particular zones, while fatigue strength measures a material’s resilience against repeated stress cycles.

Explore the “Drawing System for Special Drilling Tools”! By inputting essential tool details, you can swiftly generate straightforward diagrams illustrating special drilling tools with chamfering functions.

Home > axial cut. Subspecialties: Musculoskeletal – Total Knee Arthroplasty · Curriculum Register / Sign In. Tools. Quiz Builder Muscle Charts. Supported By.

Glassdoor gives you an inside look at what it's like to work at Diamond Square Market, including salaries, reviews, office photos, and more. This is the Diamond ...

Chamfering is often used in cooking because cutting off the corners of vegetables prevents them from collapsing during cooking and allows the flavors to soak in more easily.

R-Chamfering involves a process dedicated to curving corners, notably effective in mitigating the risk of injuries. This method excels in ensuring smoother, safer edges.

Choose the proper geometry insert for your detailed application. Choose the proper grade of the insert. To choose a proper carbide grade, the precondition is that the insert can be applied to the cutting without chip broken very soon, you can choose the harder carbide insert to get a longer tool life, the harder, the higher wear resistance, but keep the precondition in mind because too hard carbide grade can cause this problem.

Chamfering serves more than just an aesthetic purpose; it yields numerous advantages, enhancing both product quality and functionality.

Chamfered parts contribute to a uniform finish when painted or plated, resulting in a high-quality appearance that enhances the overall aesthetic appeal.

Classified by the hardness of turning workpiece materials, the turning carbide inserts can be mainly classified to be four types, there are turning inserts for P class materials, M to S class materials, K class materials, N class materials. If classify the carbide turning inserts by materials of turning workpiece name, there are turning inserts for wood turning, carbide inserts for turning aluminum and copper, carbide inserts for stainless steel, carbide inserts for cast iron, etc.

The concentricity of the cutter head, carbide inserts correctly fixed in the very precise cutter head which without abnormal vibration can last longer.

Many machinists utilize centre drills for spotting instead of real spotting drills. Center drills are designed to provide a hole suitable for a lathe centre.

Jun 5, 2022 — Prototype tooling captures the other end of the spectrum. Instead of running 24/7 for days on end, this type of tool will only be used a handful ...

The tool’s overhang length and the drill’s distance from the chamfering edge remain constant with an exchangeable head drill. This maintains dimensional accuracy during machining, significantly reducing the risk of defective workpieces.

The chamfer width exhibits irregularity, attributed to tool deflection and chatter, varying based on the machined area and the hole’s phase. As a solution, the measures shown in the previous section”Chatter in Chamfering Processes” are also effective in this case.

Carbide applied to make carbide insert, choose the proper hard origin carbide as the raw material to manufacture insert can make the carbide insert lasts longer.

1. Carbide inserts geometry custom. You can design special geometry of carbide inserts, we make special mould accordingly and manufacture this type of carbide inserts and exclusively sell to you.

0086-813-8127573

0086-813-8127573