44 Synonyms & Antonyms for TOOL - t.o.o.l.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

Please note that the Internet Explorer browser is no longer supported. We strongly recommend that you use one of the following browsers:

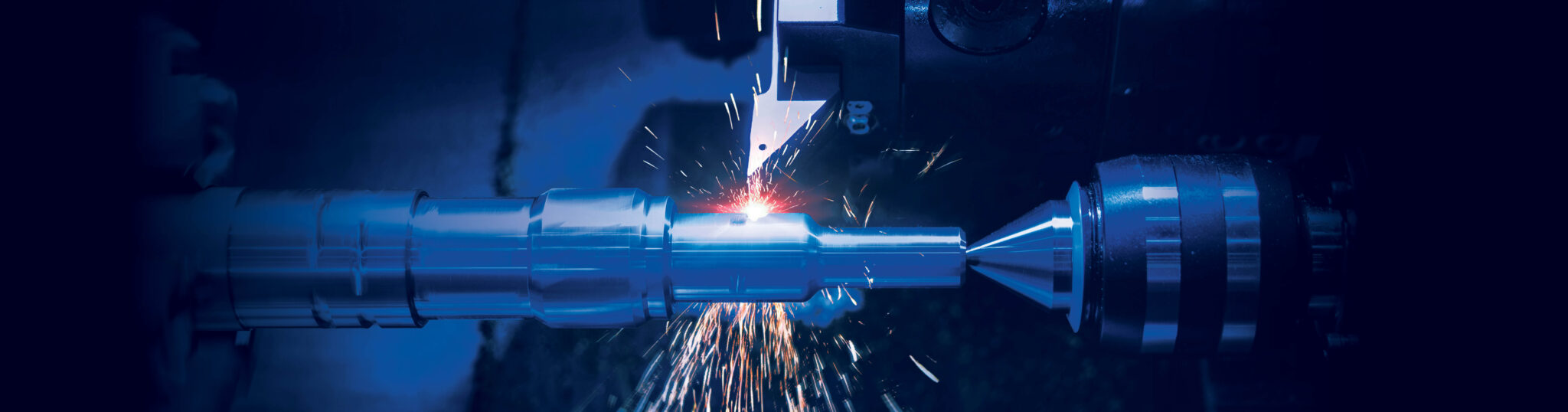

The use of graphite electrodes is common in the EDM process, providing an economical solution compared to other electrode materials, and less wear on the electrode itself. Absolute also offers a wide selection of AccuteX Die Sinkers for burning.

* The product may differ from the illustration and the price may vary by region. See the available price at the store near you by selecting your branch. Please note that additional time is required for the pickup and delivery of seasonal products.

The TMV-510G is engineered for efficient production of precision graphite electrodes and similar items. This milling machine was solely designed for machining electrodes in graphite with particular attention paid to high spindle speeds, material containment and compact size that consumes very little valuable floor space.

If you have any questions, problem with a web order or an experience to share with us, contact Patrick Morin's customer service from Monday to Friday, between 8am and 5pm.

Higher spindle RPMs are needed for faster program feed rates to achieve finer finishes. The standard RPM for the Tongtai TMV-510G is 20,000, but higher spindle speeds are offered as an option. Program feeds rates in graphite mills are also necessary for highly complex programs that are often created to cut graphite. This combination of fast RPMs and program processing is necessary for producing the finest of electrodes.

Absolute Machine Tools offers solutions for manufacturers machining graphite and burning electrodes, including the Tongtai TMV-510G and Accutex Die Sinkers.

The AccuteX Die Sinker CMAX Series is a RAM-type CNC EDM machine offering a full range of 10 different model sizes and capabilities. The fully functional C-Axis can be fit with any commercial chuck for electrode holding compatibility and can hold up to 50 pounds. Shuttle and rotary automatic electrode changers or standalone FANUC or Mitsubishi robot can be installed to accommodate untended operations from roughing to finishing changing electrodes and work pieces.

Graphite machining centers are made for electrode manufacturing with several key differences from typical machining centers which include:

Dust collection and containment components designed in tandem with a CNC machine tool are critical to managing and collecting graphite dust produced during milling, and the Tongtai TMV-510G is no exception. Absolute offers Donaldson Torit CFM dust collectors and filtration systems with piping to evacuate and collect fine graphite dust, however, other major brands of such systems can also be considered if there is a preference.

Special seals and covers are also specifically designed to protect graphite milling machines from typical wear and tear that graphite dust loves to offer. Contaminating components such as spindles and ballscrews can be very costly both in repairs and downtime. However, contamination of nearby machines can also occur, as can health issues to operators, so preventing graphite dust from escaping the work envelope is imperative.

The AccuteX Die Sinker DS ZNC (manual) series of four RAM-type EDM machines can handle maximum workpiece sizes from 38″ x 22″ x 14.9″ (965 mm x 558 mm x 378 mm) to 67″ x 39″ x 22″ (1700 mm x 990 mm x 558 mm). It’s optional COC-280 Orbit Cut System, when added to the standard Automatic Z Axis Step function, performs like a full 3D machine producing super fine finishes down to 0.18 Ra µm and accuracies to 0.0002″ easily and efficiently.

Subscribe to our newsletter now to stay in touch with all our promotional offers, tips and tricks, digital flyers and contests!

*Please note that clearance products are final sales. No returns or refunds can be made. Inventory may vary depending on availability at the branch and no in-store transfers are possible. Limited quantity, while supplies last.

Patrick Morin is a Quebec company specializing in the field of hardware that has been supporting its customers in their construction and renovation projects in Quebec since 1960.

0086-813-8127573

0086-813-8127573