44250: Sequined Sweetheart Neckline Ball Gown with ... - 44250

Some of the advantages of PVD coating can include increased durability and improved coating adhesion. However, the results can vary widely based on the quality of the process and the skill of the provider. Many companies still prefer the benefits of traditional gold plating such as:

IsCNC coolantdangerous

Cnc coolantnear me

The electroplating process applies gold or other metals to the surface of a substrate via electrodeposition. The method entails placing the workpiece into a tank with an electrolyte solution. This solution contains dissolved ions of the chosen metal — gold in this case. Consequently, some refer to the technique as ion plating. The introduction of DC electricity into the plating bath attracts the positive ions and draws them to the workpiece, where the electrodeposition then occurs.

water-basedcoolantfor machining

This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer. No other mandatory costs can be added to the delivery of a Haas CNC Product.

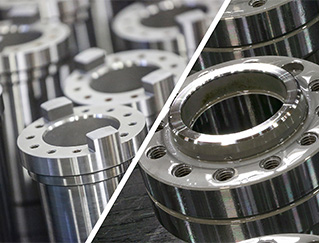

Several methods are available for applying a coating of gold onto an industrial product. The electroplating process has been the preferred choice of metal finishing companies and manufacturers for years, although a newer technique known as PVD coating is rapidly gaining traction in many manufacturing circles. We’ll explore the differences between the two to help you discover why gold plating is better for your production operations.

BestcoolantforCNCmachines

Physical vapor deposition, or PVD, is a process that many manufacturers now use for coating metals such as titanium and stainless steel. The technique involves “blasting” the gold onto another metal at a high temperature. During the process, the material moves from a condensed vapor phase that to a thin solid film. Examples of products that are compatible with PVD coating include semiconductor devices, aluminized film for packaging material and metalworking cutting tools

Coolant is the lifeblood of your Haas machine, performing a variety of functions critical to most machining operations. It removes heat from the cutting zone and workpiece, it lubricates the cutting edges during the cut, and it blasts chips and abrasive particles from the cutting zone for better surface finishes and longer tool life. Coolant also helps protect your parts and your machine from corrosion. Regular maintenance of your coolant system will keep it operating efficiently, and free of leaks.

CNCmachineCoolantPrice

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

SPC is a family-owned and operated company with more than 90 years of metal finishing expertise. We’ll be happy to help you learn more about the benefits gold plating can provide for your manufacturing operation. Contact us to request a free quote today.

0086-813-8127573

0086-813-8127573