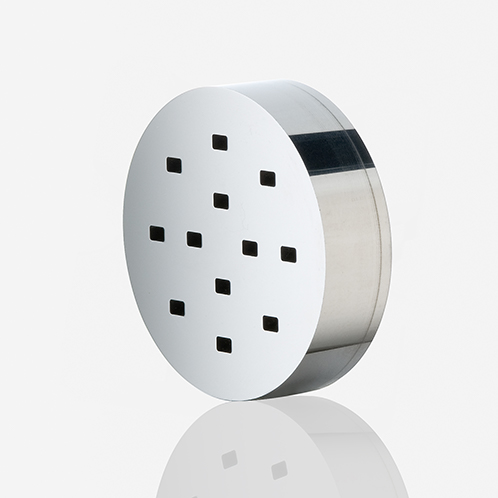

47220: Quick•Point® 52 Twin Base 146 x 76 x 168 mm - 47220

We produce tools like blanking tools and stampers (as per DIN 8583) for pressure forming as well as drawing mandrel, drawing and extrusion dies (as per DIN 8584) for tensile pressure shaping as per customer drawing – also at the micro level.

The main features of our wearing parts are individuality, high quality, and innovation. From the first feasibility studies to design, we advise you across the entire creative process of a tool and implement the highly precise manufacture of the required tools.

We can employ our extensive experience and know-how to support you with customised tool solutions. For even more specialised and tricky tasks we can manufacture special solutions that are exactly tailored to the respective application and can also be reproduced many years later.

We produce tools like blanking tools and stampers (as per DIN 8583) for pressure forming as well as drawing mandrel, drawing and extrusion dies (as per DIN 8584) for tensile pressure shaping as per customer drawing – also at the micro level.

The main features of our wearing parts are individuality, high quality, and innovation. From the first feasibility studies to design, we advise you across the entire creative process of a tool and implement the highly precise manufacture of the required tools.

Jobber length drill bits' flute length and overall length are dependant on the diamater of the drill bit. See the chart below for these specifications.

The process of making a component begins with the customer and his needs and requirements. We implement individual parts, small-scale series, and large batches perfectly and precisely according to customer wishes. Every challenge is mastered with μ-precision via competent consultancy covering material, manufacture, and deployment.

0086-813-8127573

0086-813-8127573