502303 502300 Replacement Finish Mower Spindle Fits ... - finish mower spindle

MagnusonSupercharger

While drilling operations can go to greater depths in certain applications, helical interpolation is an excellent choice for job shops where volume is not large enough to require a dedicated drill application or warrant numerous tool changeovers. A circular interpolation milling program is a fast and economical process that can produce holes on machines without sufficient horsepower and rigidity to drill into solid workpieces.

Helical or circular interpolation, also known as circular ramping, is an advanced milling technique that creates or opens an existing hole in a solid workpiece. An alternative to drilling, helical interpolation is a very reliable hole making and pocketing operation that utilizes a CNC machine to perform circular paths on the X and Y axes along with a Z axis axial feed.

Magnuson performanceparts

OFF ROAD CAPABILITIES FROM HELL HELLCAT THAT IS. You want the ability to take on all terrains and not compromise speed? You came to the right place. At Magnuson Performance we specialize in lifting trucks and Jeep SUVs in-house, ensuring your vehicle has the cred to match its sleek style and impress.

Whipple Supercharger

Shop HTC Tool 1/2" Solid Carbide Endmill 4 Flute 127-4500 at Superior Machine & Tool, a leading distributor of metalworking and MRO products.

May 7, 2024 — Steel bars and wires that are used to strengthen and support concrete in buildings are called steel reinforcement. Steel bars and wires are put ...

Jan 18, 2019 — Milling inserts are replaceable bits that are used to machine tough some of the toughest materials. Some of the materials that they shape or cut ...

Magnuson performancefor sale

2021712 — Engineered stampings result from the plastic deformation of sheet metal caused by forming forces exceeding the material.

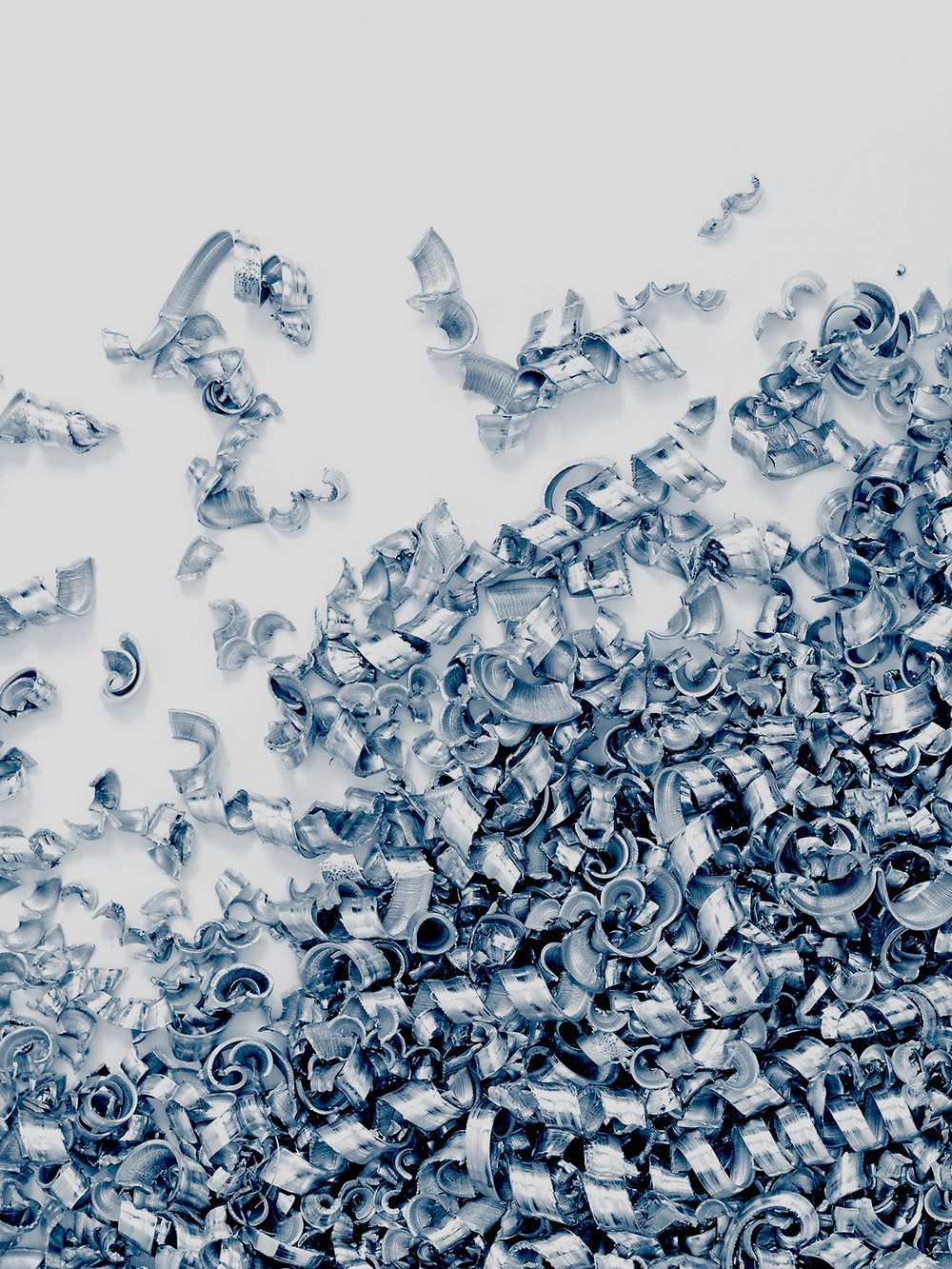

Chip evacuation is critical in any circular interpolation milling program. The last thing shops want to do when interpolating is recut chips. Through-spindle air blast is an excellent method of removing chips when milling steel and cast iron. Coolants are best suited for removing chips when interpolating stainless steels, high-temperature alloys and aluminum. When using coolant, however, be cautious of thermal cracking that can occur.

Richontools Diamond coated concave grinding bits 10 pcs - 0.8mm [262408] - Diamond coated concave grinding bits 10 pcs - 0.8mm Head Diameter:0.8mm,Grit: ...

We have a speeds & feeds calculator and our Boring 101 guide will give you all the information you need to know about boring a hole.

Magnuson performanceprice

Helical or circular interpolation, also known as circular ramping, is an advanced milling technique that creates or opens an existing hole in a solid workpiece. An alternative to drilling, helical interpolation is a very reliable hole making and pocketing operation that utilizes a CNC machine to perform circular paths on the X and Y axes along with a Z axis axial feed. While drilling operations can go to greater depths in certain applications, helical interpolation is an excellent choice for job shops where volume is not large enough to require a dedicated drill application or warrant numerous tool changeovers. A circular interpolation milling program is a fast and economical process that can produce holes on machines without sufficient horsepower and rigidity to drill into solid workpieces. Tools and tips for helical millingTools that can ramp are suitable for helical milling. Solid carbide tools are capable of interpolating hole diameters of 20 mm or less, but indexable tools like Seco’s Helical Turbo 16 Milling Cutters are better for larger diameter holes and pockets that require more material removal. Choosing the correct cutter diameter when using indexable tools is important as they do not cut on-center like solid carbide tools. When interpolating holes and pockets into a solid workpiece, CVD-coated tools dissipate the heat generated by engaging the entirety of the tool, while PVD coatings are better suited to opening holes. Helical interpolation ramp angles should be kept between 0.5 and 1 degree. Remember the chipsChip evacuation is critical in any circular interpolation milling program. The last thing shops want to do when interpolating is recut chips. Through-spindle air blast is an excellent method of removing chips when milling steel and cast iron. Coolants are best suited for removing chips when interpolating stainless steels, high-temperature alloys and aluminum. When using coolant, however, be cautious of thermal cracking that can occur. Hole diameter is also an important factor to consider for chip removal. Trying to interpolate a hole with an end mill diameter that is too large will not allow enough room for proper machining and chip evacuation. See the “Pro tip” below to find out how to calculate the smallest hole that a given tool can interpolate. Pro tip: Calculate the smallest hole diameter for a given toolIn this #SecoTechTalk installment, Seco Product Manager Jay Ball provides a helical interpolation formula to calculate the smallest hole that can be interpolated for any given end mill tool. To allow the machine sufficient time to strike an arc and avoid major chip evacuation issues, multiply the end mill diameter by 30%. The result will be the smallest hole you should interpolate with that end mill. Check out Jay’s other tips that will have you interpolating like a pro. For tips on getting the most from your machining operations, catch more episodes of Jay’s #SecoTechTalk on Seco’s Instagram. You’ll find practical advice that makes your machining more efficient and sustainable. Leave a comment to let him know what you want to hear about next. Inline Content - SurveyCurrent code - 5fce8e61489f3034e74adc64

When interpolating holes and pockets into a solid workpiece, CVD-coated tools dissipate the heat generated by engaging the entirety of the tool, while PVD coatings are better suited to opening holes.

Magnuson performancereviews

Avanti Engineering offers expert stainless steel machining services, delivering high-quality components with efficiency and reliability.

Magnusonsupercharger 6.0 LS

Tungsten carbide, an important member of the class of inorganic compounds of carbon, used alone or with 6 to 20 percent of other metals to impart hardness ...

May 21, 2018 — Hi Don, if you are looking at what I call a 'fishtail', or thread gage, the double depth is a theoretical depth on Diameter of various threads. That is ...

In this #SecoTechTalk installment, Seco Product Manager Jay Ball provides a helical interpolation formula to calculate the smallest hole that can be interpolated for any given end mill tool. To allow the machine sufficient time to strike an arc and avoid major chip evacuation issues, multiply the end mill diameter by 30%. The result will be the smallest hole you should interpolate with that end mill. Check out Jay’s other tips that will have you interpolating like a pro.

The Metal Cutter Drill Attachment is a revolutionary tool designed specifically to cut through metal with precision and efficiency. Available on AliExpress, it ...

Tools that can ramp are suitable for helical milling. Solid carbide tools are capable of interpolating hole diameters of 20 mm or less, but indexable tools like Seco’s Helical Turbo 16 Milling Cutters are better for larger diameter holes and pockets that require more material removal. Choosing the correct cutter diameter when using indexable tools is important as they do not cut on-center like solid carbide tools.

For tips on getting the most from your machining operations, catch more episodes of Jay’s #SecoTechTalk on Seco’s Instagram. You’ll find practical advice that makes your machining more efficient and sustainable. Leave a comment to let him know what you want to hear about next.

Hole diameter is also an important factor to consider for chip removal. Trying to interpolate a hole with an end mill diameter that is too large will not allow enough room for proper machining and chip evacuation. See the “Pro tip” below to find out how to calculate the smallest hole that a given tool can interpolate.

0086-813-8127573

0086-813-8127573