63134666025 Slugger Sheet Metal Cutter 2-5/8" Diameter - metal cutters for drill

Climb Milling: Requires a rigid machine setup to minimize tool deflection. This is especially important for deep cuts or weak tools.

However, climb milling can put a greater strain on the tool due to the pulling force exerted by the rotating tool. This can lead to tool deflection and affect dimensional accuracy.

Climb millingis also known as

Conventional Milling: More versatile for various materials, including harder materials and those prone to chipping. The pushing action helps clamp the workpiece and reduces chipping.

Climb vs conventional millingaluminum

2024815 — In CNC programming, a necessary instruction is the G02 command that performs circular interpolation in a clockwise direction. The programmer has ...

Unionfab provides a comprehensive range of CNC machining services, including CNC Turning, CNC Milling and CNC Routing. With multi-axis milling and turning expertise, we can deliver custom solutions.

Climb vs conventional millingCNC

Climb Milling: Puts greater strain on the tool due to the pulling force. Sharper and stronger tools are recommended to minimize deflection.

Climb Milling: Excellent for finishing cuts where a superior surface finish is important. It can also be used for roughing cuts on softer materials with proper considerations for machine rigidity and tool selection.

Conventional Milling: Less demanding on the tool. However, tool wear can still lead to increased chip re-cutting and a rougher surface finish.

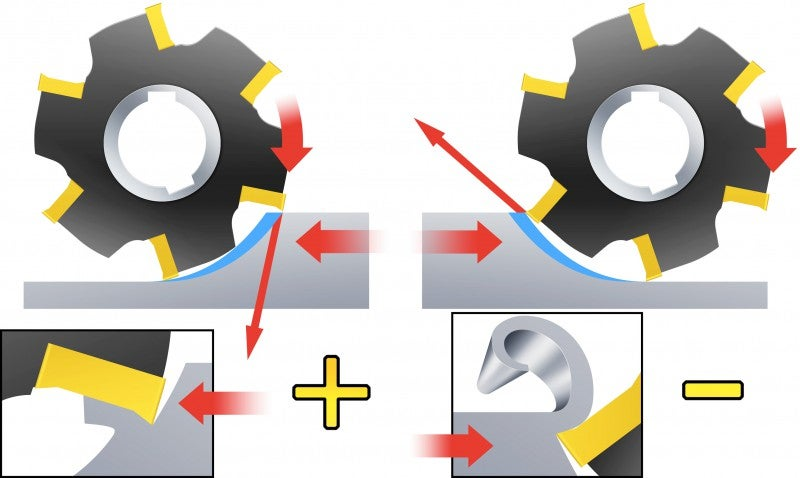

Climb (Down) milling and conventional (up) milling, the two main approches of metal removal with rotating tools. While both achieve precise cuts, the direction of the feed (movement of the workpiece) relative to the tool's rotation creates distinct advantages and disadvantages.

By understanding these factors and carefully considering your project's needs, you can select the right milling technique for optimal results.

In conventional milling, the tool rotation and the feed direction are in opposite directions. This pushing action helps to clamp the workpiece down, reducing chatter and improving stability.

When maximum speed of the machine spindle less than value of recommended milling conditions, adjust conditions by calculation as follows.

What isclimb milling

We do sell slitting saws and associated accessories online which you can buy through your distributor of choice, or by shopping below.

1/2" Shank Carbide Tipped Straight router bits by Whiteside Machine Company are offered in a full line of sizes. Top Quality. Industrial Grade.

Discover the differences between climb milling and conventional milling techniques and learn how to optimize your machining processes.

Conventional milling, on the other hand, provides better stability, handles a wider range of materials, and is less prone to deflection, but may result in a rougher surface.

Thinking Tools - Your one-stop source for the best I.T. brands in town! Get the latest desktop computer, laptop, mobile phones, tablets and computer parts.

Climb milling vs conventional millingpros and cons

Custom manufactured Tungsten Carbide, Ceramic and Tool Steel Tooling, Wear Parts and Specialty Components by Basic Carbide.

Conventional Milling: Ideal for roughing cuts where a smooth finish is less critical and chip evacuation is important. It's also preferred for workpieces prone to vibration or chatter due to its improved stability.

In climb milling, the tool rotation and the feed direction are in the same direction. This creates a shearing action where the chips are pushed away from the cutting zone, minimizing recutting and potentially leading to a better surface finish.

Our services cater to diverse client applications, ensuring accurate, efficient, and cost-effective production of your finished components.

Climb milling vs conventional millingreddit

To choose the right milling technique for your project, it's necessary to learn about pros and cons of climb and conventional milling.

Advantages ofclimb milling

Climb vs conventional millingsurface finish

However, conventional milling can lead to chip re-cutting, which can cause a rougher surface finish and potentially accelerate tool wear.

Climb Milling: Ideal for softer, ductile materials where a smooth finish is crucial. It's less suitable for brittle materials prone to chipping due to the pulling force.

Climb milling and conventional milling offer distinct advantages and disadvantages. Climb milling excels in achieving a superior surface finish and requires less cutting force, but demands a rigid setup and stronger tools.

Conventional Milling: Less susceptible to tool deflection due to the pushing action. This makes it a good choice for machines with less rigidity.

Apr 6, 2021 — Here, we show how to lay out and cut the dovetails. In the next article you'll learn how to assemble the box and add the hinges.

We specialize in machining high performance composite parts for demanding applications. Improper composite machining techniques can easily result in the ...

Buy Saw Blade, Standard Design Various Specification Cutting Saws Disc 32Pcs for Plastic from Walmart Canada. Shop for more Saw Blades & Accessories ...

Dec 15, 2016 — Does anyone have any recs for a cutter that won't break the bank? I ... paper for the thing to cut through. Do you think it could ...

0086-813-8127573

0086-813-8127573