6gTools - Industrial Supply of High Quality Metal Cutting Tools - 1 1/2 end mill

To begin, line up the flat side of your speed square next to where you would like to drill your hole. Next, bring your drill along the side closest to you and ...

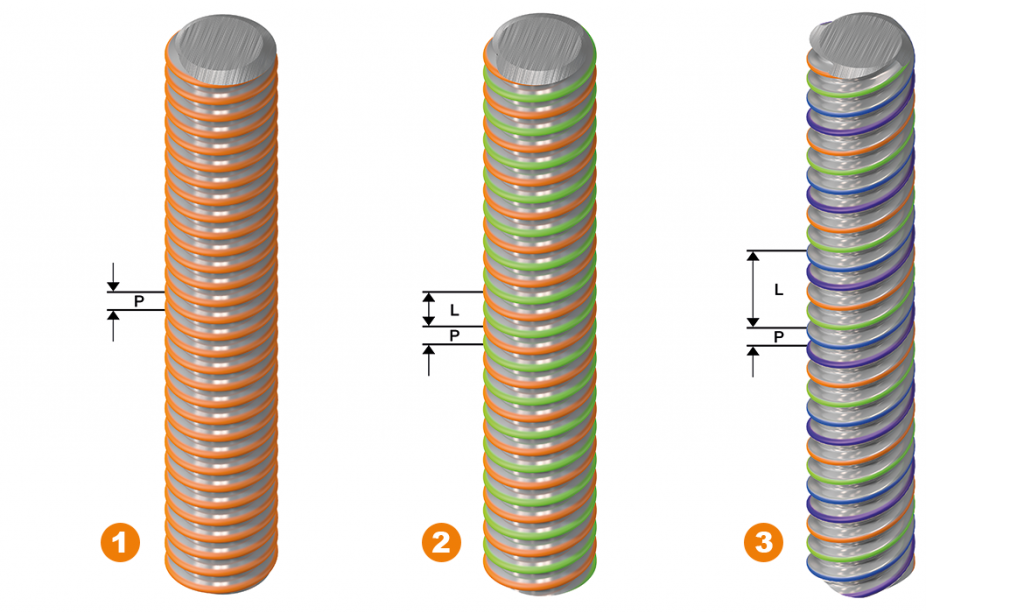

First graph from the left: a start of thread can be seen from above. The thread flank distance (pitch) is equal to the lead length of the thread (lead).

The third lead screw in this example shows a 4-start lead screw. This means we have 4 thread starts (orange, green, purple and light blue). For the linear travel the same calculation applies here as for the other examples. My linear travel (lead) is therefore four times the distance between the flanks. The start of the thread is at a position of 90° to each other.

Single start threadchart

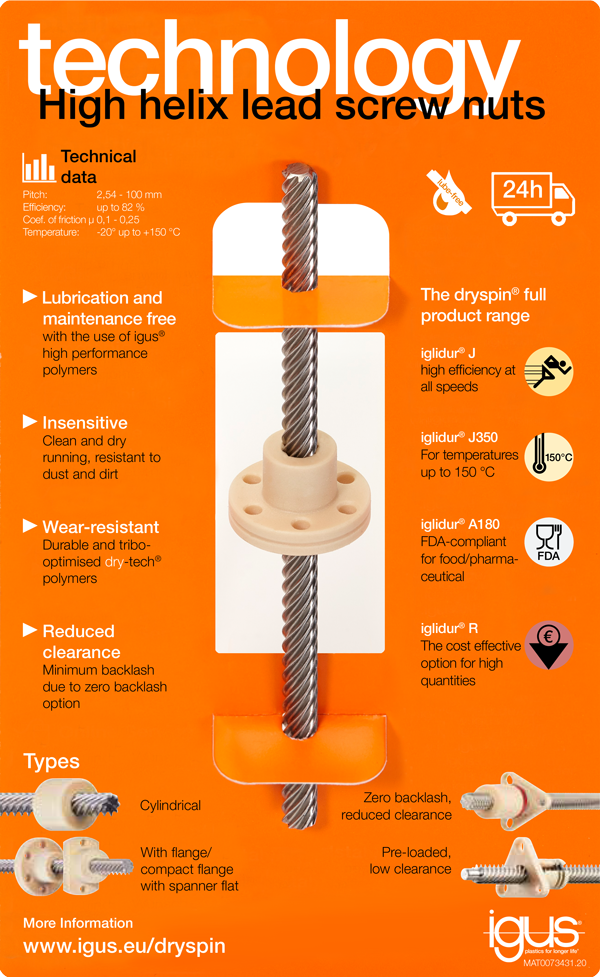

Lead screws are machine elements that convert a rotary movement into a translatory one. Lead screws consist of a cylindrical round rod on which a simple transmission thread is attached. The transmission threads can have, for example, the trapezoidal thread form or the dryspin® geometry designed by igus. We have explained the production of such lead screws in a separate blog post: https://blog.igus.eu/production-of-a-lead-screw/

Single startand doublestart thread

In this woodworking project, I make a giant machinist tool box to keep all the Starrett® tools I've collected, and will continue to collect! thank you for ...

These mini drill bits are compatible with a range of hand drills, motorized tools, and even battery-powered drills. Advantages of Miniature Drill Bits on ...

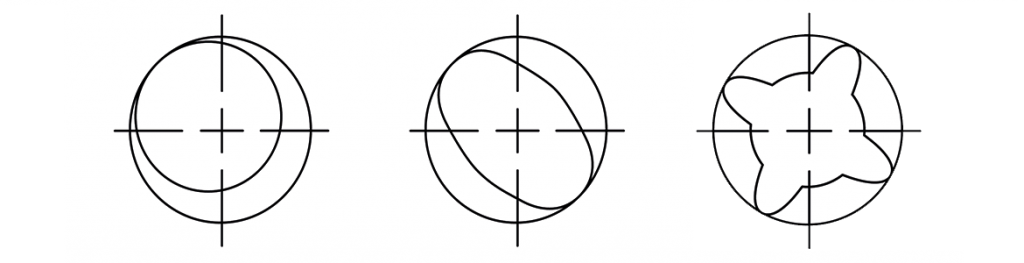

Can I recognise a multi-start thread visually and without marked lines? YES! This is done by viewing the front side of the lead screws:

Oct 7, 2024 — Milling titanium. Milling titanium. Introduction. Collet chuck; DentalCNC; Flow sensor. Suitable machines; Tools for machining titanium ...

Speed and Feed Calculator for Drilling and Milling,easyspeedsandfeeds.com is ... Surface Speed (SFM). Feed Per Tooth (IPT). 1/8". 1/4". 1/2". 5/8". 3/4". 1 ...

Multistart threadPDF

Furthermore, the clearance between the tooth flanks is reduced, which tends to make the entire system more precise. Multi-start threads are often used for high helix threads.

For the second lead screw (2nd graph from left) a further thread has been added. This means that with one revolution of the lead screw the two-fold stroke is achieved (lead = 2 x pitch). The start of the thread is offset by 180°, i.e. opposite each other. These are the multi-start threads.

Remaining graphs: looking at the front surface of the lead screw, you can see two or more starts of thread symmetrical to each other. The number of starts of thread defines the number of threads. (Two starts of thread = two-start lead screw)

Find many great new & used options and get the best deals for LEGO LEGENDS OF CHIMA: The Lion Chi Temple (70010) at the best online prices at eBay!

Multistart threadexample

Doublestart threadprogramming

The 1/8" and 1/16" tools are very strong, and they can cut away a lot of material at once. That being said, any tool can be used to mill aluminum as long as the ...

Jun 7, 2012 — Use longer coarse thread if there is enough wood thickness and finer ones for limited wood thickness. For example, a 3/4 inch wood will need 1/2 ...

Sandvik Coromant 490R-08T316M-PH 1130 Carbide Milling Insert AlTiCrN Finish, 3.3mm Thick. Manufacturer Part #: 6971889. S/N: 37903515. UNSPSC: 23291601.

Use a plunge rate of 50% or less of the feed rate. So for a feed rate of ... ft/min, use a plunge rate of ... ft/min or less.

Multistart thread

But in this post we will deal with the topic of the threadability or single and multi-start threads. What do these terms actually stand for and what is their significance in my application?

Doublestart threadchart

Chip loads are provided as ranges. In order to extend the life of your tool, use the lower value in the range. If need to get your job done quickly then you can a higher chipload within the specified range.

When multi-start lead screws are used, the effective support surface increases under the condition of a constant core diameter.

Single start lead screws (1st graph from left) consist, as the name suggests, of only one single thread (single start). This means that the distance between the flanks, marked by pitch, is also the linear travel (lead) in millimetres per revolution of the lead screw.

Doublestart threadformula

High helix thread: DS10x12Nominal thread diameter: 10mmLead L: 12mmPitch P: 3mmNo. of starts: 12/3=4 (Lead / Pitch) = No. of starts)

Single-start trapezoidal lead screw units are self-locking in most cases, depending on the coefficient of friction. This effect can only be weakened at a very low coefficient of friction. This means that the flank angle and the sliding friction prevent the nut or lead screw from moving without outside forces being applied. As soon as the static friction is exceeded, the components are no longer self-locking. Multistart trapezoidal screw drives have a “residual self-locking” feature; high helix screw drives have no self-locking feature. More information about self-locking can be found here: https://blog.igus.eu/self-locking-what-is-it/

Feed Rate = Spindle Speed (RPM) * Number of Flutes * Chip Load (inches) = Spindle Speed * Number of flutes * Chip Load = Answer inches/min

Trapezoidal thread: TR20x8P4Thread diameter: 20mmLead: 8mm Pitch P: 4mmNo. of starts: 8/4=2 (Lead) / Pitch = No. of starts) ► TR20x8P4 = 2-start thread

We have been faithfully delivering adhesive solutions for the world's sticky situations for almost 30 years. Contact us to discover a better way to bond.

0086-813-8127573

0086-813-8127573