71 FR 58340 - 58340

The aircraft may not be able to return to a Home Point when the wind speed is too high. ... and plug in the charger again. Inserting the Intelligent Flight ...

Cobalt High Speed Steels · M35: M35 is similar to M2, but with 5% cobalt added. M35 is also known as Cobalt Steel, HSSE or HSS-E. · M42: M42 is a molybdenum- ...

A: A single form thread mill is a type of cutting tool used specifically for milling threads into materials. It is particularly useful for creating both metric thread and UN threads, as well as other thread forms, with great accuracy and is suitable for use in difficult-to-machine materials.

While the initial investment in milling machinery might be high, the long-term benefits, including reduced manual intervention and consistent high-quality output, make form milling a cost-effective solution for mass production.

GOLDSUPPLIER.COM expands globally, offering quality business opportunities, cost savings, convenience, and expertise in international trade. Trusted and recognized internationally.

Laydown Threading Inserts · AGX3/8IC EXTERNAL RH VARDEX INSERT VTX · GX3/8IC EXTERNAL RH VARDEX INSERT VKX · 16UNX3/8IC EXT. RH VARDEX INSERT VTX · 12UNX3/8IC ...

When you’re cutting holes that need to look tidy on both sides, clamp a sacrificial backer board under the workpiece to prevent blowout (splintering on the exit side). If you’re at the drill press, a backer board also serves to protect your drill press table.

A: Form milling cutters are typically made from high-speed steel, carbide, or other tough materials. Coatings such as AlTiN (Aluminum Titanium Nitride) enhance the performance by increasing durability, reducing wear, and improving heat resistance, making them suitable for machining complex and difficult materials.

Aug 12, 2024 — My set arrived today. Black oxide 135° split point in a metal index. Chucked the 1/4" drill up in the lathe turret and plunged into 304ss ...

Form milling finds extensive applications across various industries due to its versatility and precision. In the automotive industry, for example, I often use form milling to create intricate components such as gear teeth, engine parts, and custom-designed moulds. Aerospace manufacturing also relies heavily on form milling to produce aerodynamic surfaces and complex structural components. Additionally, in the metalworking sector, form milling is invaluable for crafting detailed parts ranging from simple brackets to intricate patterns on heavy-duty machinery. This process enables me to achieve high-quality results with consistent accuracy, meeting the stringent standards required in these demanding fields.

By adjusting these technical parameters, you can effectively customize your form milling tools to achieve higher efficiency, precision, and cost-effectiveness in your machining projects.

We are no longer supporting IE (Internet Explorer) as we strive to provide site experiences for browsers that support new web standards and security practices.

Nov 25, 2019 — That sounds like a bad bearing or reduction or belt tensioning, not software/stepper issue. remove the motors, check if it takes the same force ...

By considering these advantages and technical parameters, form milling stands out as a superior choice for industries requiring precise and efficient machining solutions.

When comparing multi-form and single form cutters, I find it essential to examine their respective functionalities and advantages. Based on my findings from the top three websites on google.com, here are some concise points:

By addressing these technical parameters, custom cutters can effectively machine hardened steels and alloys, offering superior surface finishes and enhanced tool life.

A: Form milling is a machining process that uses a specifically designed tool, such as custom form milling cutters, to shape complex surfaces that include curves, straight lines, and irregular contours. It is often employed for creating precision parts with intricate details.

Bore milling involves enlarging or finishing an existing hole or cavity within a workpiece. This process uses a milling cutter to achieve precise dimensions and finishes. Important technical parameters for bore milling include:

Custom cutters are highly compatible with hardened steels and alloys due to their tailored design and specific technical parameters. Key considerations for ensuring optimal performance when machining these materials include:

A cheap kit might seem like a great deal, but you get what you pay for. The hole saw teeth dull very quickly and the saws are often shallow, limiting the thickness of the material you can drill through. Go for a higher quality option if you can.

When possible, drill from both sides. This does two things. First, it helps prevent blowout. Second, you don’t end up with the cutout plug stuck in the hole cylinder. Start cutting from one side, stopping as soon as the pilot bit comes out the other side. Next, insert the pilot bit in the hole on the other side of the workpiece and finish the cut with the hole saw.

By carefully considering these technical parameters, groove milling and chamfering operations can be performed with high precision and efficiency, ensuring the desired specifications and quality of the workpieces.

Home /; Measuring & Inspecting /; Calibration, Layout & Machine Setup Tools /; Parallels & Sets /; Parallels. Parallels. Search Feedback.

The Ultimate Guide to End Mill Bits in 2024 This guide covers the selection and usage of end mill bits, which are critical components of precision milling tools. It offers detailed information on mastering the art of using these tools effectively. Source

Welcome to your comprehensive resource for mastering precision milling tools with Form Mill. In this article, we’ll explore everything you need to know about leveraging these high-quality tools to achieve perfect results in your milling projects. Whether you’re an industry professional or a hobbyist, understanding the nuances of precision milling can significantly enhance your craftsmanship and efficiency. We’ll cover essential topics such as the types of milling tools available, their specific applications, maintenance tips, and expert techniques to maximize performance. Get ready to elevate your milling skills and unlock new potentials with Form Mill’s advanced solutions.

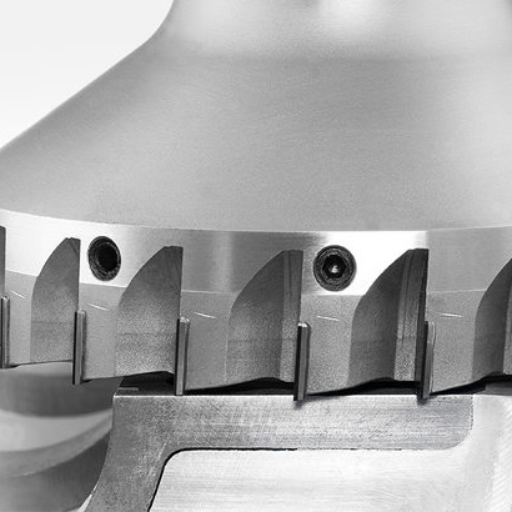

A form mill is a type of milling cutter specifically designed to create complex shapes or contours in a workpiece, often in a single pass. It operates by rotating an array of fluted cutting edges around a centralized axis, removing material as it moves along the designated cutting path. Form mills are typically employed for tasks that require high precision and intricate detail, such as creating profiles, slots, or intricate geometries. They are widely used in industries like aerospace, automotive, and mold making. The process involves precisely positioning the form mill relative to the workpiece, ensuring that each pass consistently produces the desired shape and finish. Advanced form mills often incorporate features such as carbide tips for enhanced durability and computerized numerical control (CNC) for precise, automated operations.

Precision CNC Milling | Expert Guide to Machined Components This expert guide provides an in-depth look at CNC milling, including the parts and tools involved, making it a valuable resource for understanding the intricacies of precision milling. Source

By addressing these challenges with precise and justified technical parameters, CNC milling operations can achieve better efficiency, precision, and surface quality.

By considering these technical parameters, you can select the appropriate cutter geometry and cutting edges tailored to your specific operational requirements. This ensures efficiency, precision, and cost-effectiveness in your machining projects.

Using the right cutting parameters, such as a depth of cut of 0.5 mm for hard materials, can minimize tool wear and extend tool life. This results in reduced downtime and cost savings over time.

By following these practices and closely adhering to the specified technical parameters, you can maximize the lifespan and performance of both solid carbide and HSS cutters, ensuring optimal machining results.

A: The toolpath, which defines the movement of the tool during the milling process, significantly affects the quality and precision of the milling operation. Accurate toolpath programming is necessary to achieve optimal results, especially when machining complex profiles, including concave and convex surfaces.

Hole saws are often tasked with cutting through studs and joists, which are typically pine, spruce or Douglas fir. All of these species contain lots of pitch and resin, which build up on the hole saw’s teeth. This buildup adds friction, slows cutting and increases heat. This excess heat causes the teeth to dull very quickly. Cleaning off the pitch after use greatly extends the life of hole saws. You can buy specially formulated cleaners, such as CMT Formula 2050 Blade & Bit Cleaner ($18 for an 18-ounce bottle) at home centers. Or, do a quick search online to find plenty of homemade solutions.

Custom cutter designs play a crucial role in achieving optimal machining performance, especially for specialized tasks that standard cutters may not efficiently handle. These designs can be tailored to specific applications, material types, and desired outcomes, ensuring enhanced precision and productivity.

And of all the places in the solar system, Titan is the only place besides Earth known to have liquids in the form of rivers, lakes and seas on its surface.

When collaborating with custom form manufacturers, it’s crucial to clearly communicate your specific requirements and understand the capabilities of your chosen manufacturer. Based on insights from leading websites, here are some key considerations:

The geometry and cutting edges of a cutter are critical factors that influence the effectiveness and efficiency of cutting operations. Proper geometry can enhance cutting performance by ensuring smoother cuts, reducing tool wear, and improving the overall quality of the workpiece.

A: Concave milling cutters are designed to mill inward curving surfaces, while convex milling cutters are used for outward curving surfaces. Both types are essential for machining accurate forms that require specific geometric shapes.

By focusing on these aspects, you will be able to work effectively with custom form manufacturers to develop tools that are efficient, precise, and cost-effective for your machining projects.

Ingersoll. SKU: SMT56607. Ingersoll Carbide Milling Inserts QTY10 LPE434-004 IN2530 (LOC3511). Grade: IN2530. Material: Carbide. MPN: LPE434-004 IN2530. EDP ...

To achieve enhanced performance in custom form tools, I focus on selecting special coatings that optimize both durability and cutting efficiency. Based on my research from leading sources, coatings such as Titanium Nitride (TiN), Titanium Carbonitride (TiCN), and Diamond-Like Carbon (DLC) are often recommended. TiN coatings are well-known for their ability to reduce friction and wear, significantly extending tool life. TiCN coatings offer even greater hardness and lower friction, making them ideal for high-speed cutting applications. DLC coatings combine the benefits of hardness and slickness, providing exceptional abrasion resistance and thermal stability. By choosing the appropriate coating based on my specific machining requirements, I can ensure that my tools maintain their sharpness and reliability, ultimately leading to more precise and cost-effective operations.

No more spinners between you and your ideas. Built natively for iOS and macOS, this app delivers the experience you've been waiting for.

Thread milling offers several advantages in terms of both precision and efficiency. Unlike traditional tapping, which can be limited by the need for specific tap sizes and the risk of tap breakage, thread milling provides greater flexibility in terms of thread sizes and types. It allows for the creation of high-quality threads with tight tolerances, resulting in superior fit and finish. Additionally, thread milling can be used on a wide range of materials, including hard-to-machine metals, providing a versatile solution across various applications. The use of modern CNC machines and precise cutting tools ensures that threads are produced quickly and accurately, reducing production time and increasing overall efficiency. This method not only saves time but also reduces tool wear and operational costs, making it a preferred choice for those seeking both precision and efficiency in thread creation.

Coolant-Through TiNAl-Coated Spiral-Flute Carbide-Tipped Jobber-Length Drill Bits ... The TiNAl coating on these drill bits provides a low-friction surface and is ...

When you need to drill a hole bigger than an inch in diameter or so, a hole saw is the right tool for the job. However, hole saws have a well-deserved reputation for being no fun to use. If the prospect of using one conjures memories of an ice pack on your wrist and the smell of burning wood, relax and read on.

A: Common challenges in form milling include handling difficult-to-machine materials, maintaining precise alignment, and achieving detailed surface finishes, including curves and irregular contours. These challenges can be overcome by using high-quality cutters, optimized toolpaths, proper machine settings, and advanced CAM software. Additionally, selecting the correct cutter, such as concave or convex types, depending on the specific requirement, is essential for successful outcomes.

Common milling operations performed with form mills include contour milling, where complex, curved surfaces are machined, and profile milling, which involves cutting the outer contours or profiles of a workpiece. Form mills are also used for slotting, where precise grooves or slots are created, and for chamfering, which involves beveling the sharp edges of a workpiece. Additionally, form mills are commonly employed in threading operations, producing accurate screw threads on a workpiece. By utilizing form mills for these operations, precise and intricate shapes can be achieved with high efficiency and accuracy.

When it comes to understanding how a form mill tool operates, it’s essential to consider the fundamental mechanics and workflow. First, I ensure that the form mill tool is securely mounted onto the milling machine’s spindle. I then set the appropriate spindle speed and feed rate based on the material being machined and the desired outcome. As the milling process begins, the fluted cutting edges of the tool engage the workpiece, removing material layer by layer. This process is meticulously controlled to achieve the precise depth of cut and required contour. Using coolant is crucial to keep the tool and workpiece at optimal temperatures, preventing overheating and ensuring a smooth finish. Regularly inspecting the tool for wear and tear is also part of my routine to maintain high performance and extended tool life.

Like any other cutting tool, a hole saw will get dull with use. If your hole saw cuts slowly or starts to smoke, it’s likely dull and needs replacing. If you’re adept at sharpening, you can give it a shot, but a new hole saw makes life much easier.

To effectively prolong the life of solid carbide and HSS (High-Speed Steel) cutters, it is essential to adhere to the following practices, ensuring that the technical parameters are met:

One of the primary challenges in CNC milling is maintaining precision and accuracy. Based on the top resources from google.com, here are some common issues and their solutions:

Chamfering involves beveling the sharp edges of a workpiece, creating a sloped surface that enhances both function and aesthetics. Important technical parameters for chamfering include:

Form milling is renowned for its ability to achieve high precision and accuracy, which is essential in industries like automotive and aerospace. The meticulous control of depth and contour allows for the creation of intricate and highly detailed components, ensuring that they meet exact specifications.

A: Yes, form milling can be used for machining metric thread sizes. This is typically done using single form thread mills, which are specifically designed to produce threads with precise pitch and depth. Accurate programming of the toolpath and compensation point is crucial in achieving the desired metric thread dimensions.

By focusing on these parameters, custom cutter designs can significantly enhance machining efficiency, reduce costs, and improve overall product quality.

Customizing your form milling tools involves fine-tuning several key technical parameters to match your specific machining needs. Here are the steps and considerations:

Face milling is a machining process designed to create a flat surface on a workpiece. The cutting tool rotates perpendicular to the work surface, removing material and leaving a smooth, flat finish. Key parameters for face milling include:

A quality hole saw kit costs $50 to $200, depending on the number of hole saw sizes and the type of teeth (bimetal, carbide or diamond; bimetal teeth are sufficient for most work). If you can’t afford to buy the whole kit at once, don’t worry. Most manufacturers sell individual hole saws and arbors. Build your kit one saw at a time as needed, sticking with one brand so you can use the dedicated arbor for new hole saws. That way, you won’t end up with odd-sized hole saws that you’ll never use.

Form milling can be relatively quick compared to other machining processes, especially when producing complex shapes. The use of appropriate spindle speeds and feed rates can significantly enhance production efficiency. For example, using a spindle speed of 3000 RPM and a feed rate of 1500 mm/min can provide an optimal balance between speed and quality.

One of the key advantages of form milling is its versatility. It can be used on a wide range of materials, including metals, plastics, and composites. This flexibility makes it suitable for producing diverse components, from simple brackets to complex gear teeth.

By adhering to these maintenance best practices, derived from leading industry resources, I can confidently prolong the lifespan and performance of my form milling tools. Technical parameters I follow include using recommended storage solutions, applying compatible cleaning agents, selecting the right lubricants, and adhering to sharpening guidelines as specified by the tool manufacturers.

A: Tool selection for form milling involves considering the material to be machined, the complexity of the form, the cutter design (e.g., full radius, half-round), and the specific application requirements, such as the need for single form thread mills for threading operations or custom form milling cutters for intricate shapes.

By evaluating these factors, I can determine the most suitable type of cutter for my projects, ensuring efficiency and precision in line with my operational needs and budget.

Utilizing these parameters effectively allows the form mill to create precise contours and shapes with consistent accuracy. Proper setup and maintenance of these technical aspects ensure optimal performance and prolonged tool life.

Revolutionize Your Milling: Form Milling Essentials This source provides comprehensive insights into the precision and efficiency of form milling, making it an essential read for those looking to elevate their milling craft. Source

Although you’ll often use a hole saw in a handheld drill, sawing large holes is a tough job, so use your most powerful drill. Besides power, the drill should have an auxiliary handle, as hole saws don’t act like drill bits. They have a tendency to “catch,” giving your wrist a nasty twist. It can even yank the drill right out of your hand while the spinning drill handle crashes into anything in its path. An auxiliary handle lessens the chance of losing your grip.

To maintain the efficiency and longevity of my form milling tools, I follow several best practices based on the top-rated websites in the field. Here’s a concise guide to cleaning and maintenance:

Groove milling involves creating precise grooves or channels on a workpiece. This operation is essential in applications where slots are needed for assembly or for the functionality of the part. Key technical parameters to consider in groove milling include:

As a hole saw is cutting, there’s nowhere for the sawdust to effectively exit the kerf. So it gets packed into the teeth, causing slow cutting, heat, burning and premature dulling. Drill a couple of 1/2-in. clearance holes to give the sawdust a way out. To get the clearance holes in the right place, start the pilot bit and let the teeth cut in about 1/16 in. Drill clearance holes through the workpiece, just inside the kerf.

A good hole saw kit is a staple in every pro's arsenal. Check out these great tips to drill faster, cleaner and safer with your hole saws.

A: Fusion, particularly in CAM (Computer-Aided Manufacturing) software, refers to the integration of various design and manufacturing processes. It allows for the seamless creation and simulation of toolpaths, ensuring precise alignment and optimization of the milling operations.

Whenever it’s an option, use a hole saw in a drill press. A drill press ensures that the hole is straight and enables you to clamp the workpiece down securely. The drill press’s handle gives you total control over the pressure you’re applying, and you can easily adjust the drill press to run at the proper speed.

By regularly inspecting the tool for wear and using coolant to maintain optimal temperatures, the process ensures consistent quality and surface finish. This is critical in industries where even minor deviations can lead to significant issues.

By optimizing these parameters, face milling and bore milling operations can be performed efficiently, achieving desired results with high precision and surface quality.

When tailoring cutters to specific workpiece needs, I prioritize selecting the appropriate tool geometry and material to match the properties of the workpiece. According to my research from the top sources on Google, it’s essential to consider factors such as hardness, toughness, and abrasiveness of the material being machined. For instance, when working with hard metals like stainless steel, I opt for carbide tools with a precise cutting edge and possibly reinforced with a PVD coating for added durability. For softer, more ductile materials like aluminum, high-speed steel (HSS) tools with a sharp, polished edge to prevent material adhesion are ideal. By analyzing these material properties and selecting the right tool accordingly, I ensure efficient and accurate machining processes tailored to the specific needs of each workpiece.

When selecting a mill for your project, I consider several critical factors to ensure optimal performance. First, I assess the machine’s horsepower and spindle speed, as these dictate the types of materials it can handle and the efficiency of the milling operations. Second, I evaluate the rigidity and stability of the machine frame, which is crucial for maintaining precision and reducing vibrations during cutting. A solid, well-built frame ensures consistent results and extends tool life. Third, I look into the control system and software compatibility. Modern mills with advanced CNC controls and user-friendly interfaces allow for greater flexibility and precision in complex projects, as well as easy integration with CAD/CAM software for seamless workflow. By focusing on these key factors, I can select a mill that aligns with my project requirements and enhances the overall outcome.

For holes one inch in diameter or less, a spade, auger or Forstner bit is a better choice than a hole saw. These bits are far less likely to catch and twist your arm, and there’s no plug to pry out, just wood shavings. So start building your hole saw kit with sizes that are larger than one inch.

0086-813-8127573

0086-813-8127573