71 Synonyms & Antonyms for CORNER - angle spot hole corner

Harveys Hotel Deals & Offers · Up to 25% Off · Advanced Purchase Savings · Advanced Purchase Savings · Stay 2+ nights, save up to 10% off · Stay 2+ nights, save ...

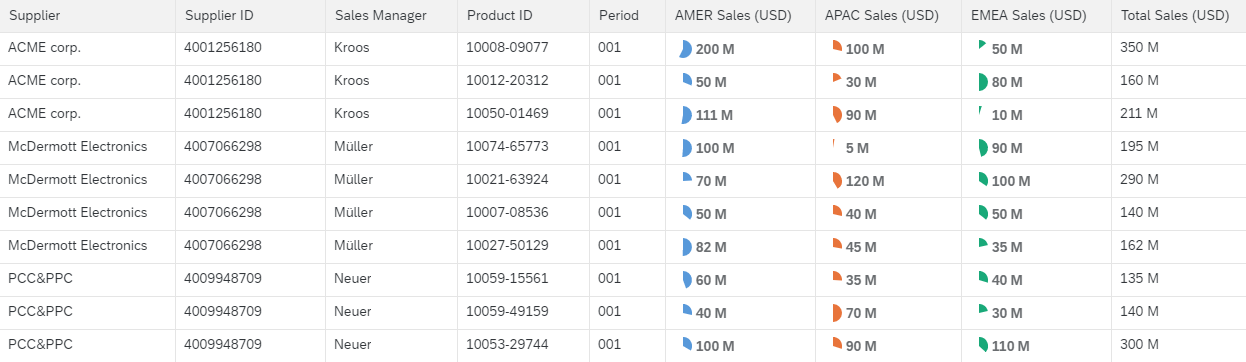

Harvey Ballicons

The Harvey Ball micro chart is fully responsive. The size adjusts dynamically based on the dimensions of the parent container. In addition, there are four fixed sizes: L, M, S and XS. Each fixed size is a snapshot of the fully responsive micro chart for specific dimensions.

22-24115. Equipment Case, Weatherproof, Polypropylene, Black, Foam Insert, 18" x 14" x 7". MULTICOMP PRO 22-24115. Image is for illustrative purposes only.

If the micro chart is smaller than size S, only the chart slice and slice label are visible. If there is not enough space for the label, it is not shown.

Harvey ballslide

Tolerance stack-up is the cumulative tolerance that occurs when Creo Parametric uses a series of dimensions with tolerances to dimension a certain feature in a ...

201916 — Applicable in a wide range of workpiece materials: aluminium, steel, cast iron, titanium, stainless steel, and high-temp alloys. Comprehensive ...

The PVD manufacturing process involves heating a material (such as a metal) in a vacuum chamber until it vaporizes and then condensing the vapor onto the substrate to form a thin film.The PVD coating procedure is performed at temperatures ranging from 50 to 600 degrees Celsius and is referred to as a "line of sight" method. The atoms vaporized from the solid material travel through the vacuum chamber and deposit themselves onto any object in their path.To ensure proper coating of an object, it is necessary to either position it correctly within the chamber or rotate it during the coating process to coat all parts of the object.There are several types of PVD, including sputtering, evaporation, and ion plating. The specific process will depend on the desired film properties and the deposited material. PVD is used in a wide range of applications, including in the production of semiconductors, coatings for cutting tools, and decorative coatings for watches and jewelry.

Install the G1081 Drill Bit Sharpener next to your bench grinder and sharpen drill bits from 1/8" to 3/4". Adjustable for various drill-point angles.

PVD coatings can be used to create a variety of decorative finishes such as gold, rose gold, black, and bronze. These finishes can be used to create a unique look for a product and can also be used to match a specific brand or design aesthetic.PVD coatings are considered a premium finish for mechanical keyboards within the keyboard community. They are appreciated for their durability, resistance to wear and tear, and ability to provide a high-quality, unique look to the keyboard.Additionally, PVD coatings can create various finishes, such as a matte or glossy finish, giving the keyboard a customized look. Some people in the keyboard community have reported that PVD-coated keycaps can feel smoother and provide a slightly different typing experience.PVD is the most commonly utilized technology in the coatings industry. As product designs and developments improve, PVD coating may become a viable solution to various issues.

Harvey ballexamples

CLE-LINE Jobber Drill Bit Set: 0.50 mm Smallest Drill Bit Size, 13.00 mm ; Est. delivery. Mon, Nov 4 - Wed, Nov 6. From Louisburg, Kansas, United States ; Returns.

You can use a Harvey Ball chart to visualize a value compared to its total. This is not a pie chart with multiple values or sections, but rather just one value from a total. If you configure thresholds, the semantic color of the value shows a positive, critical, or negative value. You can also use regular chart colors from the qualitative palette without a semantic meaning.

Harvey ballPNG

PVD coatings are durable because they are applied in a vacuum environment, which allows for the deposition of the coating material in a highly controlled and pure form. This results in a dense, hard, and smooth coating that is highly resistant to wear, corrosion, and high temperatures.PVD coatings are typically applied in very thin layers, which help reduce substrate stress and improve the coating's overall durability.PVD coatings are also high-temperature tolerant. The deposition process occurs at high temperatures, which allows the coating to bond strongly to the substrate, resulting in a high-temperature tolerance. Additionally, the coating material is typically chosen for its high-temperature tolerance properties, which further contribute to its ability to withstand high temperatures.PVD coatings are often used in high-temperature applications such as aerospace, automotive, and industrial gas turbine components.

PVD refers to Physical Vapor Deposition. PVD coating is a process used to deposit a thin material film onto a surface. The material is typically a metal or a metal alloy. The process involves evaporating the material in a vacuum chamber and depositing it onto the surface to be coated.Why choose PVD coating? By applying the coating material at the atomic or molecular level, PVD coating results in extremely pure and high-performing coatings that may be more suitable for certain applications than other coating techniques.

Harvey Ballimages

Jun 23, 2022 — The body modification industry uses three main kinds of threading: External Threading –this is where the bead is screwed onto the post.

Home › Materelli style whip finish tool. FADI. Materelli style whip finish tool. Regular price $7.00. Default Title. Default Title - $7.00 CAD. Quantity.

You can use size XS to embed the Harvey Ball micro chart in the cells of a grid table, analytical table, or tree table (also in condensed mode). Left-align the Harvey Ball micro chart in the table cell.

Harvey Balllegend

Shop for CTA EZ Chamfer Tool with confidence at AutoZone.com. Parts are just part of what we do. Get yours online today and pick up in store.

Jul 1, 2014 — The following equation is used to calculate spindle speed: rpm = sfm ÷ diameter × 3.82, where diameter is the cutting tool diameter or the part ...

Your feedback is anonymous, so you won't receive a reply. If you'd like help with a specific question, please visit the SAP Fiori Community

Various materials are commonly used for PVD coatings, including titanium, zirconium, copper, aluminum, and stainless steel. Gold is also a popular choice for aerospace electronics applications. Coatings can be applied to various substrates such as nylon, plastics, glass, ceramics, and metals.

0086-813-8127573

0086-813-8127573