81 FR 22514 - 22514

Nickel alloyPrice per kg

It is to one’s benefit to have a bigger percentage of axial forces than radial forces. Having more axial forces than radial forces. When there is a large radial force acting on the cutting process, it may have an adverse influence, which may result in vibration and a poor surface quality. This may be the case when there is an excessive amount of radial force acting on the cutting operation. As a general rule of thumb, you should choose a nose radius that is either the exact same size as the depth of cut or a little smaller size than the depth of cut.

Negative angle inserts have an orientation that sends the cutting forces farther back from the edge of the insert by using a combination of negative axial and negative radial rake angles. This allows the cutting forces to be directed further away from the edge of the insert. The rake angle is the result of combining these angles together.

It is essential to have a machine that has the necessary power, in addition to a rigid setup, in order to ensure that the cutting tool and the workpiece are securely attached. Cast iron is an excellent material for using negative angle insert geometries; however, in order to make advantage of these geometries, a stiff setup is required. Also, keep in mind that recent developments in technology have made it possible to include chip breakers inside inserts. This is something that was previously impossible. Because of this, modern negative angle inserts may be machined with a larger degree of flexibility than was previously feasible. This was not the case in the past. Because of this, negative angle inserts are capable of processing a wide variety of materials effectively provided that the appropriate chip groove profile is used.

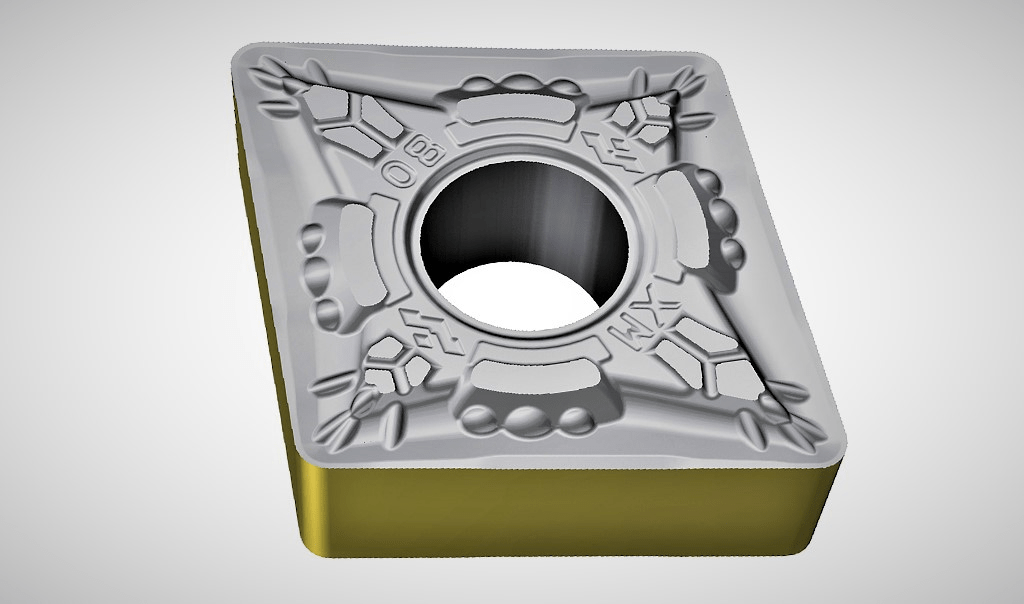

The relief angle of negative inserts, like the VNMG insert depicted in the figure, is equal to zero. This is because negative inserts have a negative thickness. Because of this, the two sides of the insert seem exactly the same, yet both sides include edges that may cut.

Nickel alloygrades

The insert grade is chosen in large part with consideration given to the following criteria: the component material (ISO P, M, K, N, S, or H); the kind of procedure (finishing, medium, roughing) The working conditions of the machine (good, average, difficult)

It should come as no surprise that the first letter in the codes for the inserts indicates the form of the insert, whilst the second letter in the code specifies the clearance angle. On the description chart is an insert with the number CCMT120206. The second letter “C” in this letter sequence indicates that the clearance angle is 7 degrees. In this instance, the angle is more than 0 degrees, which is why we refer to it as a positive angle insert. In the same vein, an insert with the coding VNMG160804 reveals that the second letter is a “N.” You can tell that it is a negative angle insert since the explanation chart has the letter “N” next to the clearance angle of 0 degrees. The bottom line is that the presence of the letter “N” in an insert code indicates unequivocally that the insert is made of carbide.

If you are still unsure what type of alloys would be most suitable for your needs, why not head over to our Contact Us page and get in touch with our in-house Metallurgist who will be happy to help you out!

Controlled-Expansion Alloys – Offer high strength and low coefficient thermal expansion. For example, Alloy 902, 903, 907, and 909.

Inserts with a positive angle of attack are typically utilized for cutting through softer materials. Less force is needed to cut through it. However, the cutting edge becomes less effective as the positive value of the rake angle increases. The cutting edge of the tool has a greater propensity to be severed when there is force exerted on the tool. Using inserts with a positive angle makes the tool sharper and more pointed, but they also lower the cutting edge’s strength. It contributes to the avoidance of the creation of build-up edge chip in ductile materials and aids in the production of continued chip in ductile materials.

The geometry of the insert and its grade are complementary to one another. For instance, the toughness of a grade may make up for a lack of strength in an insert geometry if the insert geometry is designed properly.

When performing turning operations, it is essential to take into account the nose radius, sometimes referred to as the RE. Inserts are available for purchase in a variety of nose radius diameters in a wide range of sizes. The selection, which is controlled by the depth of cut and the feed rate, has an effect on the surface finish, chip breaking, and insert strength. Both of these factors are impacted by the selection.

Clearance angle, single-sided cutting, positive angle insert, low cutting forces, side clearance, and angle of clearance are some of the features that are included.

On the other hand, any carbide inserts that do not include the letter “N” in the second position are considered to be positive angle inserts. Single-sided cutting, minimal cutting forces, and side clearance are only some of the characteristics that are offered by the positive angle inserts. In addition to this, it is an excellent option for turning relatively thin components internally as well as turning them outside. Negative angle inserts, on the other hand, can be single or double-sided, have zero-clearance, are designed for heavy cutting circumstances, and have great edge strength.

Nickel alloysteel

The geometries of inserts may be broken down into three fundamental types that are most suited for finishing, medium, and roughing operations respectively.

The link that exists between the nose radius and the depth of cut is one factor that might have an effect on the vibrational tendencies. The radial forces that are responsible for driving the insert away from the cutting surface become more axial as the depth of cut increases. These forces are caused by the increase in the depth of cut.

Soft Magnetic Alloys – These nickel-iron alloys also offer magnetic permeability properties used principally in switchgear and for direct current motors and generators.

Finishing Inserts: Operations using finishing inserts should be performed at shallow depths of cut and slow feed rates. Operations that need just a little amount of cutting force.

When it comes to selecting the appropriate insert, finding the insert that is most suited to the task at hand is just half the fight. The last step consists of choosing the most appropriate grade and chip breaker.

In the following paragraphs, we will explain how to go about picking the most appropriate insert shape and grade for the particular duties you have. When selecting an insert, there are a lot of different factors to think about. In order to obtain effective chip control and machining performance, it is important to carefully pick the insert geometry, insert grade, insert shape (nose angle), insert size, nose radius, and entry (lead) angle.

Positive inserts, like the VBMT insert seen in the picture, have a relief angle that isn’t equal to zero. This is because positive inserts are inserted into holes that are already drilled. The insert has cutting edges on the opposite side of the component from which it was cut. The underside of the blade is not appropriate for cutting and serves no use other than to rest on the pocket of the tool holder. The insert depicted in this example is a V with a 35-degree angle, but the same general idea applies to any shape, including D, R, S, T, and so on.

Nickel alloyvs stainless steel

Determine the appropriate size of the insert based on the requirements of the application as well as the available area for the cutting tool in the application. When the insert size is increased, the stability also increases. Insert sizes typically greater than IC 25 millimeters are used for heavy-duty machining (1 inch). After completion, there is often the possibility of shrinking the size.

Negative inserts are the most lasting and dependable solution for roughing and general turning applications because of the sturdy inserts shapes and thickness. This is due to the fact that negative inserts provide larger feed rates and deeper depths of cut than other kinds of inserts. When completing, the use of positive inserts is nearly always the optimum option since, in comparison to other kinds, they give lower cutting pressures. As a result of this, it is feasible to complete the cutting process at shallower depths, which will result in a reduction in vibration. The price of a positive and negative insert is practically the same; however, if you acquire twice as many cutting edges as you did before, the price that you pay for each cutting edge will be cut in half. This is because the price of an insert is determined by the number of cutting edges that are purchased. Get in contact with HUANA if you have any questions or concerns about positive angle inserts and negative angle inserts, or if you are interested in purchasing either kind of insert.

Both positive and negative angle inserts relate to the angle of the cutting edge in relation to the machined surface. Positive angle inserts have a positive angle, and negative angle inserts have a negative angle. The rake angle of the cutting tool is defined as the angle of orientation of the tool’s rake surface from the reference plane (R), and it is measured on some other plane. It is possible for it to be referred to by a variety of names, some of which depend on the plane on which it is projected and measured. At the same time, the rake angle might have a positive value, a negative value, or perhaps no value at all depending on the angle at which the rake surface is inclined with respect to the reference plane. Each of these three varieties comes with its own unique set of benefits and drawbacks. This value has the potential to affect the cutting force and power consumption during machining, as well as the life of the cutting tool, chip deviation, shear angle, tool life, and other factors. The rake angle has an indirect impact on machinability as well.

Nickel alloyuses

Negative inserts are the strongest and best solution for roughing and standard turning applications because their solid forms and thickness allow for greater depths of cut and higher feed rates. The most common Negative Inserts are CNMG (rhomboid 80 degree), DNMG (diamond 55 degree), and WNMG (trigon 80 degree). With a 45-degree approach angle that allows for greater depths of cut and lower cutting loads, SNMGs are a good choice for heavy roughing jobs.

Nickel-based alloys have an extensive history in the use of warfare. The use of nickel dates to the ancient Roman era when nickel featured in the manufacture of Roman armour.

Welding Alloys – Additions of aluminium, titanium, magnesium and other elements are made to the filler metals and welding electrodes to provide better weld effects and to over-come any hot-short cracking and malleability problems.

However, nickel came into the limelight during the First and Second World Wars and in the ensuing Cold War. Nickel-based alloys were used for guns, ammunition, tanks and more. For instance, the Germans built a portable bridge using nickel-iron alloy during the Second World War.

A positive insert will have a clearance angle that is more than zero degrees, while a negative insert will have a clearance angle that is greater than zero degrees but less than ninety degrees (for example, 7 degrees of clearance). The negative type insert explains how the insert need to be constructed so that it will tilt appropriately when it is put in the holder.

Nickel alloycomposition

The clearance angle is where the primary difference between inserts with a positive angle and inserts with a negative angle may be found.

Nickel alloyproperties

Nickel-Copper Alloys – Possess outstanding corrosion resistance in reducing chemical environments and in seawater, where they serve as excellent materials for nuclear submarines and various surface vessels. By changing the ratio of nickel and copper in the alloy, a whole series of alloys with different electrical resistances can be created. Prime amongst these alloys is Alloy 400 and Alloy K500.

Inserts with a negative angle are used to cut through materials with a high strength rating since they are stronger. When inserts with a negative angle are utilized, the cutting edges may gain enhanced strength, which is beneficial.

Nickel-lron Low-Expansion Alloys – Developed for the lamp and electronics industries where glass-to-metal seals in sealed environments are important. Prime alloys are Alloy 42 and Alloy 426.

Medium Inserts: Operations ranging from medium to light roughing. A diverse selection of depth of cut and feed rate combinations are available.

To begin, inserts with negative angles often have clearance angles of zero degrees. On the other hand, the positive angle inserts will always have a clearance angle that falls somewhere between 0 and 90 degrees.

Defence, especially marine applications Energy generation Gas turbines, both flight and land-based, especially for high-temperature exhaust Industrial furnaces and heat exchangers Food preparation equipment Medical equipment Laboratory equipment In nickel plating, for corrosion resistance As a catalyst for chemical reactions Mobile phones Pharmaceuticals Building materials Nuclear power systems Power cables Batteries Jewellery

Some cutters retain the positive angle inserts in such a manner that it provides a positive rake angle both axially and radially. This allows for highly free cutting as well as clean and silent machining. This configuration not only provides very low cutting force but also achieves a great surface finish, work hardening on the surface is reduced to a minimum, and excellent surface finish. Machining non-ferrous materials, such as aluminum, copper, and non-metallic materials, and even steels on smaller machines with low power ratings is possible using geometries like these. Because they are more delicate (which can result in cutting edge chippage) and have the potential to pull the workpiece off the table, these positive angle inserts require a special amount of care during the setting up process.

Nickel alloyexamples

Roughing Inserts: Combinations of a high feed rate, and depth of cut for the cut. Operations that need the most cutting-edge level of security.

Because of this quality, double Negative angle cutter inserts are able to display stronger insert strength when compared to positive/negative cutters and double Positive angle cutter inserts. Positive angle cutter inserts also have this feature. Due to the geometry of double negative angle inserts, there is a possibility of poor chip flow, which might lead to worries about clogging. The geometry of these inserts is like this despite the fact that they are quite robust and durable.

Nickel is obtained through extractive metallurgy : it is extracted from the ore by conventional roasting and reduction processes that yield a greater than 75% purity metal. In many stainless steel applications, 75% pure nickel can be used without further purification, depending on the impurities.

The two distinct types of inserts have certain similarities in their qualities, which are outlined in the following list:

Insert with a negative rake angle, which may be utilized either double-sided or single-sided, has a high edge strength, has zero clearance, is the ideal choice for external turning, and is effective for heavy cutting situations.

The relief angle is represented by the letter that comes after the first letter in the name of an insert (for example, B in VBMT). N signifies 0 degrees, a negative insert. A non-zero angle, often known as a positive insert, is denoted by any other letter (E.g., B is 5 degrees, C is 7, P is 11). (E.g., B is 5 degrees, C is 7, P is 11). If the second letter of the insert’s name is an N, then the number of cutting edges on the insert will often rise by a factor of two. This is because N is the letter that comes second in the insert’s name. If the letter is anything other than an N, then you will only receive cutting edges on one face. As an example, VBMT160408 only has two edges, but VNMG160408 has four edges.

There are thousands of uses for nickel, and nickel-based alloys are one of the most common metals you would find. Some examples of the uses of the application of nickel are:

Nickel-based alloys are materials that are composed mainly of nickel and some other alloys. Otherwise known as Ni-based alloys, they are well-known for their excellent strength and corrosion resistance. They have superior resistance to heat and so, are often found in high-temperature environments.

When completing, positive inserts are always the ideal option since they generate reduced cutting forces and allow you to cut at lower depths, avoiding vibration. The most common Positive Inserts are CCMT (rhomboid 80 degree), DCMT (diamond 55 degree), VCMT or VBMT (diamond 35 degree).

Make use of wiper inserts to provide either a better surface finish while retaining conventional cutting data or a maintained surface finish while drastically increasing feed rate. The wiper geometry known as WMX is First Choice, and it serves as an excellent place of departure for the vast majority of applications. There is always a fruitful option available, even when the circumstances change. In the event that vibration issues arise, using a wiper shape that is positive will help reduce the amount of force required and keep production levels stable.

When choosing the form of the insert, consideration should be given to the appropriate level of accessibility for the tool’s entry angle. In order to ensure the insert’s strength and dependability, the nose angle should be increased to its maximum achievable value. Having said that, this aspect needs to be weighed against the several different cuts that have to be carried out. A big nose angle is robust, but it calls for a greater amount of machine power and has a greater propensity to vibrate. A tiny nose angle is weaker and has a smaller cutting edge engagement, both of which might make it more vulnerable to the effects of heat. A large nose angle, on the other hand, has a larger cutting edge engagement.

Nickel-Chromium – Provide higher strength and resistance in extremely high temperatures. Prime alloys are Alloy 600, Nimonic alloys including N80a, Alloy X750, Alloy 718, Alloy 625. Alloy C-22, and Alloy C-276.

Lost in the Middle Ages, nickel was used once again in the 1890s as the Americans discovered they could manufacture it into armour plates.

Iron-Nickel-Chromium Alloys – Used in high-temperature petrochemical environments, where sulphur-containing materials are cracked into component distillate parts. Prime alloys in this class are Alloy 800 / 800HT, Alloy 825 and Alloy 925.

0086-813-8127573

0086-813-8127573