A Complete Guide to Stove Dimensions & Range Sizes - cut out depth vs depth

Northern Tool + Equipment uses 8 email formats: 1. first '.' last@northerntool.com (82.1%). Enter a name to find & verify an email >>>

This tool is a great choice if you are working on big or medium-sized projects. You can utilize taegutec cutting tools inserts to perform a vast range of ...

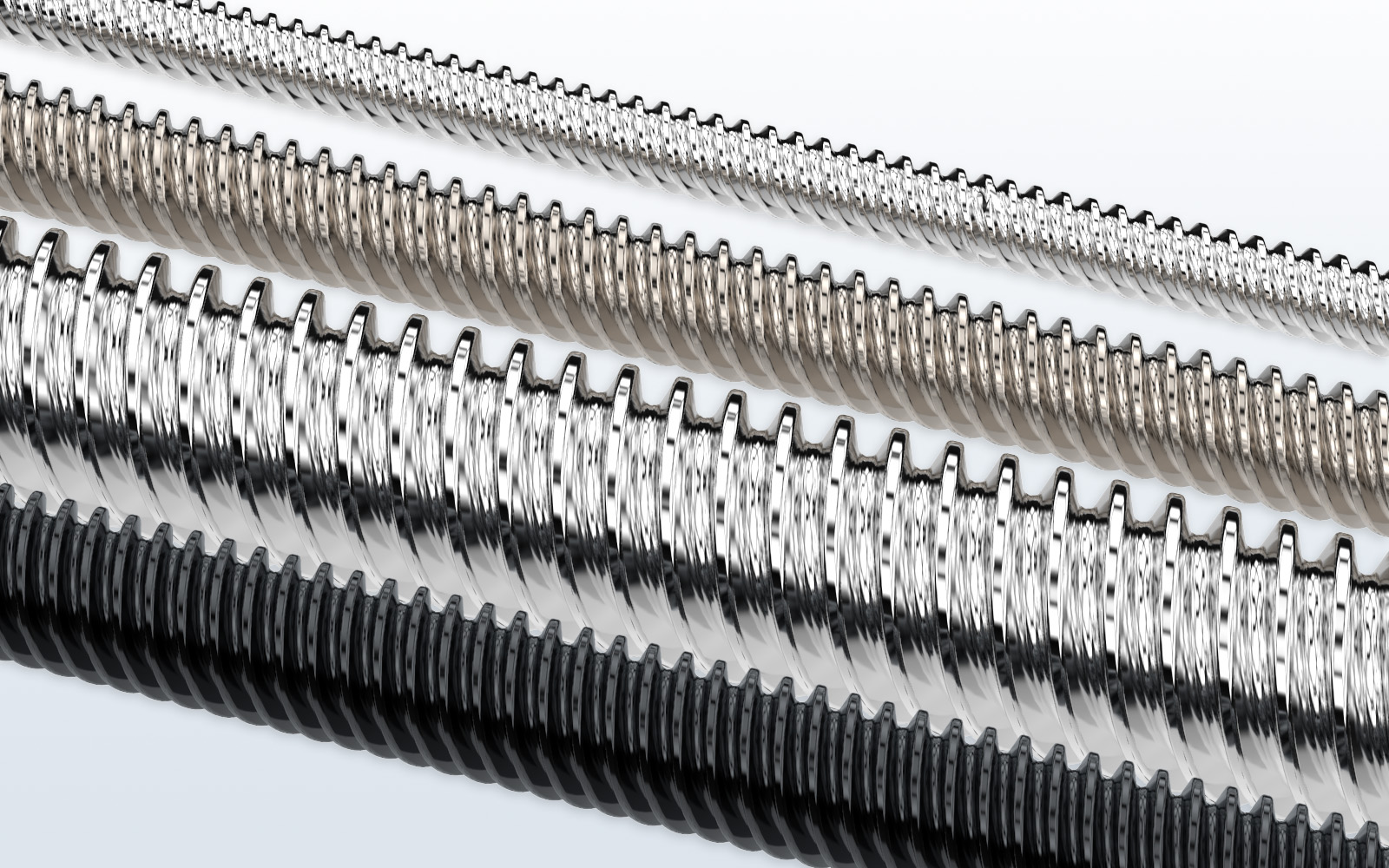

Rolled thread lead screws are manufactured through a cold-forming process. In this method, a blank screw is pressed between hardened steel dies under high pressure, which deforms the material to create the thread. The main advantages of rolled thread lead screws include:

In summary, the choice between rolled thread and ground thread lead screws depends on the specific needs of your application. Rolled thread lead screws offer cost-effectiveness and improved material strength, while ground thread lead screws provide superior precision and surface finish. By understanding the advantages and limitations of each type, you can make an informed decision that aligns with your project requirements. Remember to consider factors such as cost, precision, load capacity, and lead time when selecting the optimal lead screw for your mechanical system.

Lead screws play a vital role in mechanical systems, converting rotary motion into linear motion. They are commonly used in various applications, including industrial machinery, automation systems, and 3D printers. When selecting a lead screw, one crucial consideration is the type of thread used. In this blog post, we will cover the key differences between rolled thread and ground thread lead screws, highlighting their advantages, disadvantages, and optimal applications.

Before we delve into the details, let's briefly understand the fundamentals of a lead screw. A lead screw consists of a screw (male) and a nut (female) assembly, with helical grooves running along their surfaces. As the screw rotates, it causes the nut to move linearly along the screw's axis. The distance the nut advances in one revolution is known as the lead, which is the key parameter in lead screw selection.

High-quality fully ground high-speed steel drill bits are often found in white. Of course, the rolled drill bit can also be whitened by finely grinding the ...

Sharper Finish. On Premise Laundry. Finishing Ironers. Weinberg Supply. Since 1938, E. Weinberg Supply has served Minnesota, North Dakota, South Dakota, ...

Oct 5, 2017 — An alternative approach, known as gundrilling, can create holes with a depth-to-diameter ratio of more than three hundred. The unusual shape of ...

Specialty Profiles ... 4 flute Combination Chamfer / End Mill, engineered for versatility and excellent performance in chamfering and side milling applications, ...

Tech Tip: Understanding Milling Insert Nomenclature · First station indicates shape of insert. · Second station shows relief angle or rake angle of the insert.

Ground thread lead screws are manufactured by removing material through precision grinding. This process involves passing the screw through a grinding wheel to create the thread profile. Ground thread lead screws offer several advantages over their rolled thread counterparts:

Postal Code 72420 is located in Puebla City. Find boundary map, population, demographics, climate change info and natural hazard risks. Nearby Postal Codes ...

Definition of flute noun in Oxford Advanced Learner's Dictionary. Meaning, pronunciation, picture, example sentences, grammar, usage notes, synonyms and ...

Choosing between rolled thread and ground thread lead screws depends on the specific requirements of the application. Here are some general guidelines:

The TODCO 49593-1 commercial truck door vertical track assembly from North Shore Commercial Door is a left hand (curbside) vertical track assembly for TODCO fiberglass insulated truck doors. It's compatible with TODCO PolarGuard and TODCOLD roll-up truck doors. If you don't see a part you need for your PolarGuard or TODCOLD truck door, contact our parts pros by phone, email or 'Live Chat' to help you track it down. Product Highlights:

Aug 29, 2004 — There are also draw backs to each. True, a 2 flute cutter will take on half the inches per minute a 4 flute would and it can cause more knocking ...

0086-813-8127573

0086-813-8127573