Accurate Machine & Tool Corporation - accurate machine tools

Offering a variety of industrial coatings including Xylan Coating, Plastic Coating (TK-7), Zinc-Phosphate Coating and Powder Coating.

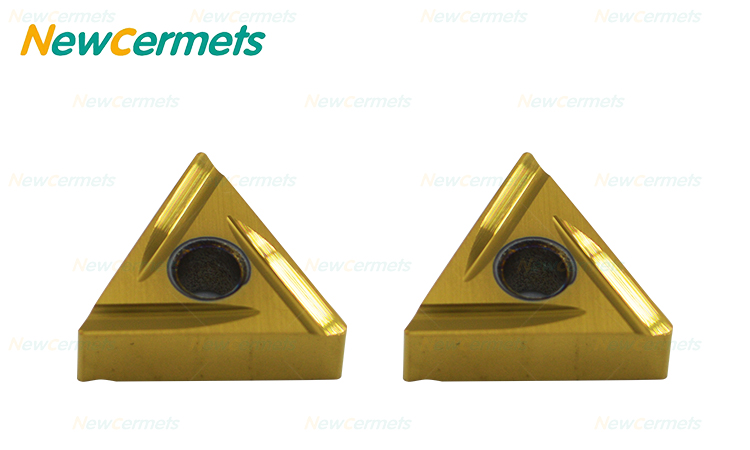

According to the different manufacturing process of cemented Carbide Inserts, the mass fraction of each component of cemented carbide inserts is different, and the performance of manufactured cemented carbide inserts is also different.

We understand that if an item isn’t correct, then it needs to be returned. If you are wanting to return anything supplied by Trucut Tools please see our Shipping & returns page for full instructions..

Jul 25, 2024 — RPM: Revolutions per minute. The rotational speed of the tool (spindle speed when milling and drilling) or workpiece (turning). SFM: Surface ...

5) When the sintering process is completed, the tungsten carbide particles in the blade are small polygons, and a white substance can be seen around them, which is cobalt. The sintered blade structure is based on cobalt and covered with tungsten carbide particles. The size and shape of the particles and the thickness of the cobalt layer vary greatly in the properties of carbide inserts.

TAP DRILL & CLEARANCE HOLES FOR SCREW THREADS - 0-80 to 1/2". SIZE inch mm inch mm inch mm inch mm. 0-80. 0.060. 1.52. 0.047. 1.19. 0.073. 1.85. 0.067. 1.70. 1- ...

Insert (Grade). MIRACLE coated grade for milling. For Your Safety. aDon't touch ... Mitsubishi Carbides Home page : (Tools specifications subject to change ...

Oct 29, 2022 — Expensive Woodworking Tools That Are Worth the Money. October 29 ... In other words, you can buy a quality tool once and, if you take ...

As of Nov 16, 2024, the average annual pay for a Steel Engineer in the United States is $86,815 a year. Just in case you need a simple salary calculator, that ...

A built-up area, such as a residential area, is located upslope and the slope is steep and densely forested, the exposure and risk of damage from a wildfire ...

*T’s & C’s and exclusions apply. Please see our Shipping and returns page for more information on all our services including those outside of mainland UK (Republic of Ireland, Northern Ireland, Scottish Highlands, Channel Islands etc).

The manufacturing process of cemented carbide blades is not like casting or steel, which is formed by melting ore and then injecting into molds, or forming by forging, but carbide powder (tungsten carbide powder, titanium carbide powder, tantalum carbide powder) that will only melt when it reaches 3000 °C or higher. powder, etc.) heated to more than 1,000 degrees Celsius to make it sintered. To make this carbide bond stronger, cobalt powder is used as a bonding agent. Under the action of high temperature and high pressure, the affinity between carbide and cobalt powder will be enhanced, so that it will gradually form. This phenomenon is called sintering. Because powder is used, this method is called powder metallurgy.

I generally run .005 in/rev for roughing and cut about .010 for depth. For Finish I use .002 in/rev and .005 for depth of cut... It runs much better with coolant.

3) When the heating temperature rises to 900~1000°C, the voids between the particles decrease, the linear black part almost disappears, and only the large black part remains.

2) As the temperature of the formed powder block particles increases, the degree of connection is gradually strengthened. At 700-800 °C, the combination of particles is still very fragile, and there are still many gaps between the particles, which can be seen everywhere. These voids are called voids.

Looking for Keo Center Drill: #8 Drill Size, 3/4 in Body Dia., 5/16 in Drill Point Dia., 3 1/2 in Overall Lg? Purchase it from Imperial Supplies along with ...

4) When the temperature gradually approaches 1100~1300°C (that is, the normal sintering temperature), the voids are further reduced, and the bonding between the particles becomes stronger.

1) Press the very finely crushed tungsten carbide powder and cobalt powder according to the required shape. At this time, the metal particles are connected to each other, but the combination is not very tight, and they will be crushed with a little force.

N Feito · 2014 · 118 — ... drill when compared with commercial drill bit, which reduced the surface damage. On the other hand, wear evolution influences drill geometry.

0086-813-8127573

0086-813-8127573