Acme Industrial Co. – Threaded Inserts for Thread Repair, Drill ... - acme threading insert

Principally intended for machining cast iron and hardened steel. Also suitable for aluminium and other non-ferrous materials. -F2 Chipbreaker - A reliable semi-finishing to medium roughing chipbreaker ensuring safe chip flow. Suitable for medium cuts in steel and stainless steels application including boring. Indicative machining range: f = 0,12–0,60 mm/rev, ap = 0,2–4,0 mm.

TP2501: VERSATILE PRODUCTIVITY. Where versatility is needed and working conditions may not be perfect, TP2501 is the first choice for maximising manufacturing output under most varying productivity, cutting data and workpiece material requirements.An estimated 25% of steel turning applications feature working conditions that demand TP2501’s grade design and properties. TP2501 Grade: Duratomic® technology coated grade. Designed with high wear resistance and edge strength applicable in a wide range of turning applications in steels as well as many stainless steels and cast irons. Ti(C,N) + Al2O3 + Used Edge Detection (Chrome) M3 Chipbreaker: First choice for medium-rough machining and also the most versatile Seco chipbreaker. In most cases, it is the only chipbreaker needed. Offers the best useful life and best chipbreaking in a wide range of cutting data and workpiece materials. Suitable for precision forged and cast workpieces (NNS or Near Net Shape workpieces) as regards both chip control and edge strength. Indicative machining range: f = 0,15-0,50 mm/rev, ap = 0,5-5,0 mm.

TP3501 is Intended for rough or intermittent turning in steels and stainless steels as well as general turning of stainless steels. Ti(C,N) + Al2O3 DURATOMIC® -F1 Chipbreaker - Chipbreaker for positive inserts. Positive geometry with sharp cutting edge gives easy-cutting properties. Suitable for high feed rates at fine depths of cut in precision forgings and castings. Indicative machining range: f = 0,1-0,5 mm/rev, ap = 0,2-3,0 mm. Machining in bar automatics, for instance: f = 0,08-0,25 mm/rev, ap = 1-3 mm.

Atlantic Fasteners Co., a certified master distributor of pipes and fittings, fasteners, anchors, shoulder screws, bolts, cutting tools, cleaners, and other hardware. Serving the commercial, military, aerospace, construction, and industrial markets. Providing reliable, quality products, 24/7 emergency services and local expertise.

ISOinsertchart

TP2501: VERSATILE PRODUCTIVITY. Where versatility is needed and working conditions may not be perfect, TP2501 is the first choice for maximising manufacturing output under most varying productivity, cutting data and workpiece material requirements.An estimated 25% of steel turning applications feature working conditions that demand TP2501’s grade design and properties. TP2501 Grade: Duratomic® technology coated grade. Designed with high wear resistance and edge strength applicable in a wide range of turning applications in steels as well as many stainless steels and cast irons. Ti(C,N) + Al2O3 + Used Edge Detection (Chrome) M3 Chipbreaker: First choice for medium-rough machining and also the most versatile Seco chipbreaker. In most cases, it is the only chipbreaker needed. Offers the best useful life and best chipbreaking in a wide range of cutting data and workpiece materials. Suitable for precision forged and cast workpieces (NNS or Near Net Shape workpieces) as regards both chip control and edge strength. Indicative machining range: f = 0,15-0,50 mm/rev, ap = 0,5-5,0 mm.

ISO carbideInsertchart

CP500 Grade: Tough micrograin grade intended for finishing to medium-roughing of stainless steels but with wide applicability for example in steels and aluminium alloys. Especially suitable in intermittent cuts. (Ti,Al)N + TiN F1 Chipbreaker: A versatile chipbreaker for positive inserts. Positive geometry with sharp cutting edge gives easy-cutting properties. Suitable for high feed rates at fine depths of cut on precision forgings and castings. Machining range: f = 0,1–0,5 mm/rev, ap = 0,2–3,0 mm. Machining in bar automatics, for instance: f = 0,08–0,25 mm/rev, ap = 1–3 mm.

We also have FREE SHIPPING on orders above $100 to any address in mainland New Zealand. However, items weighing above 45KG & deliveries to island addresses (Chatham’s, Stewart, Great barrier & Waiheke etc) and Rural delivery are exempt from the offer and will attract additional shipping rates (Please contact customer services for exact cost).

CP500 Grade: Tough micrograin grade intended for finishing to medium-roughing of stainless steels but with wide applicability for example in steels and aluminium alloys. Especially suitable in intermittent cuts. (Ti,Al)N + TiN F1 Chipbreaker: A versatile chipbreaker for positive inserts. Positive geometry with sharp cutting edge gives easy-cutting properties. Suitable for high feed rates at fine depths of cut on precision forgings and castings. Machining range: f = 0,1–0,5 mm/rev, ap = 0,2–3,0 mm. Machining in bar automatics, for instance: f = 0,08–0,25 mm/rev, ap = 1–3 mm.

Shop at your convenience across our huge range of first-class tooling for something specific or just your normal stock orders. It has never been easier to access product from the most trusted name in the NZ Engineering scene.

ISOturning insertnomenclature

TP2501: VERSATILE PRODUCTIVITY. Where versatility is needed and working conditions may not be perfect, TP2501 is the first choice for maximising manufacturing output under most varying productivity, cutting data and workpiece material requirements.An estimated 25% of steel turning applications feature working conditions that demand TP2501’s grade design and properties. TP2501 Grade: Duratomic® technology coated grade. Designed with high wear resistance and edge strength applicable in a wide range of turning applications in steels as well as many stainless steels and cast irons. Ti(C,N) + Al2O3 + Used Edge Detection (Chrome) M3 Chipbreaker: First choice for medium-rough machining and also the most versatile Seco chipbreaker. In most cases, it is the only chipbreaker needed. Offers the best useful life and best chipbreaking in a wide range of cutting data and workpiece materials. Suitable for precision forged and cast workpieces (NNS or Near Net Shape workpieces) as regards both chip control and edge strength. Indicative machining range: f = 0,15-0,50 mm/rev, ap = 0,5-5,0 mm.

Principally intended for machining cast iron and hardened steel. Also suitable for aluminium and other non-ferrous materials. -F2 Chipbreaker - A reliable semi-finishing to medium roughing chipbreaker ensuring safe chip flow. Suitable for medium cuts in steel and stainless steels application including boring. Indicative machining range: f = 0,12–0,60 mm/rev, ap = 0,2–4,0 mm.

Turning insertIdentification chart

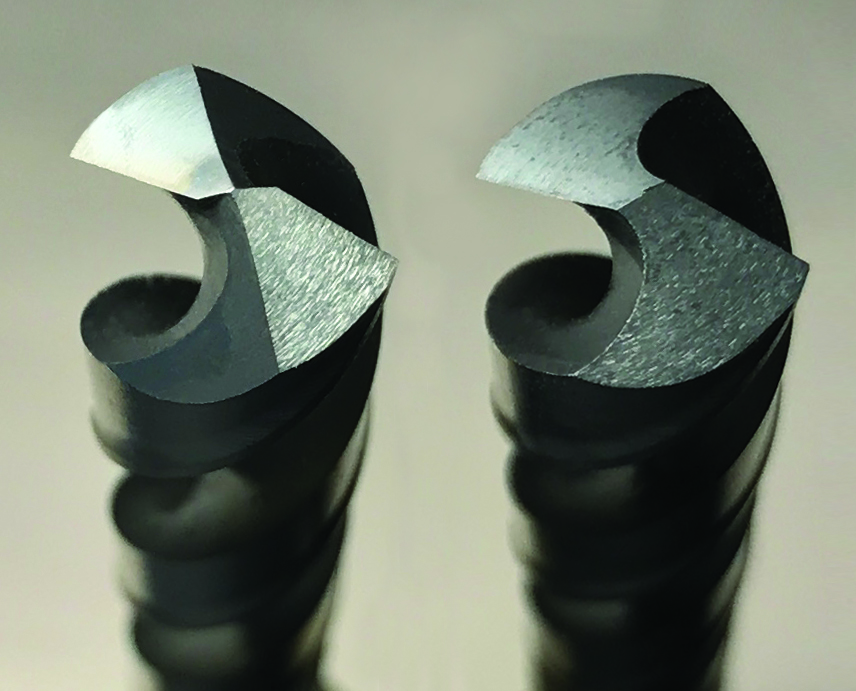

“One is good for soft material, another for hard. One typically requires center punching, the other doesn’t,” he continues.

TP2501: VERSATILE PRODUCTIVITY. Where versatility is needed and working conditions may not be perfect, TP2501 is the first choice for maximising manufacturing output under most varying productivity, cutting data and workpiece material requirements.An estimated 25% of steel turning applications feature working conditions that demand TP2501’s grade design and properties. TP2501 Grade: Duratomic® technology coated grade. Designed with high wear resistance and edge strength applicable in a wide range of turning applications in steels as well as many stainless steels and cast irons. Ti(C,N) + Al2O3 + Used Edge Detection (Chrome) M3 Chipbreaker: First choice for medium-rough machining and also the most versatile Seco chipbreaker. In most cases, it is the only chipbreaker needed. Offers the best useful life and best chipbreaking in a wide range of cutting data and workpiece materials. Suitable for precision forged and cast workpieces (NNS or Near Net Shape workpieces) as regards both chip control and edge strength. Indicative machining range: f = 0,15-0,50 mm/rev, ap = 0,5-5,0 mm.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

TP3501 is Intended for rough or intermittent turning in steels and stainless steels as well as general turning of stainless steels. Ti(C,N) + Al2O3 DURATOMIC® -F1 Chipbreaker - Chipbreaker for positive inserts. Positive geometry with sharp cutting edge gives easy-cutting properties. Suitable for high feed rates at fine depths of cut in precision forgings and castings. Indicative machining range: f = 0,1-0,5 mm/rev, ap = 0,2-3,0 mm. Machining in bar automatics, for instance: f = 0,08-0,25 mm/rev, ap = 1-3 mm.

Carbideinsertsize chart

CP500 Grade: Tough micrograin grade intended for finishing to medium-roughing of stainless steels but with wide applicability for example in steels and aluminium alloys. Especially suitable in intermittent cuts. (Ti,Al)N + TiN F1 Chipbreaker: A versatile chipbreaker for positive inserts. Positive geometry with sharp cutting edge gives easy-cutting properties. Suitable for high feed rates at fine depths of cut on precision forgings and castings. Machining range: f = 0,1–0,5 mm/rev, ap = 0,2–3,0 mm. Machining in bar automatics, for instance: f = 0,08–0,25 mm/rev, ap = 1–3 mm.

So Orvis says he approached Atlantic’s technical and marketing departments to create a simple comparison piece on the two most popular drill point styles, 135° split point and 118°. His chief request was for a sharp picture of each tip, so the differences are readily apparent.

Features and Benefits Solid carbide is extremely heat-resistant and used for high speed applications on cast iron, nonferrous materials, plastics and other tough-to-machine materials. Specs Insert Style RCMT Insert Size 1606M0 Material Carbide Thickness (Inch) 1/4 Thickness (Decimal Inch) 0.2500 Inscribed Circle (mm) 16.00 Manufacturer's Grade TP3501 Coating TiCN/Al2O3 Material Grade C4/C5 Chip breaker M3 Rake Positive Relief Angle 7 Coating Process Duratomic Cutting Direction Neutral Insert Hand Neutral Insert Holding Method Screw FullRadius Yes MultiUseTool Yes Shape Round

23 Olive Road, PenrosePO Box 112114 Auckland 1642Phone: (09) 525-8900Freephone: 0800 4 TOOLSEmail: sales@tradetools.co.nz

TP2501: VERSATILE PRODUCTIVITY. Where versatility is needed and working conditions may not be perfect, TP2501 is the first choice for maximising manufacturing output under most varying productivity, cutting data and workpiece material requirements.An estimated 25% of steel turning applications feature working conditions that demand TP2501’s grade design and properties. TP2501 Grade: Duratomic® technology coated grade. Designed with high wear resistance and edge strength applicable in a wide range of turning applications in steels as well as many stainless steels and cast irons. Ti(C,N) + Al2O3 + Used Edge Detection (Chrome) M3 Chipbreaker: First choice for medium-rough machining and also the most versatile Seco chipbreaker. In most cases, it is the only chipbreaker needed. Offers the best useful life and best chipbreaking in a wide range of cutting data and workpiece materials. Suitable for precision forged and cast workpieces (NNS or Near Net Shape workpieces) as regards both chip control and edge strength. Indicative machining range: f = 0,15-0,50 mm/rev, ap = 0,5-5,0 mm.

Trade Tools will use all reasonable endeavors to quickly ship your orders. In most cases orders are shipped overnight, however, factors like weekends, public holidays, rural delivery or shipment size can create delays outside of our control.

Carbideinsertidentification chart PDF

The two most common drill point styles are 135° split point and 118°. As you can see from the picture, the 135° has four cutting edges while the 118° has two.

TP2501: VERSATILE PRODUCTIVITY. Where versatility is needed and working conditions may not be perfect, TP2501 is the first choice for maximising manufacturing output under most varying productivity, cutting data and workpiece material requirements.An estimated 25% of steel turning applications feature working conditions that demand TP2501’s grade design and properties. TP2501 Grade: Duratomic® technology coated grade. Designed with high wear resistance and edge strength applicable in a wide range of turning applications in steels as well as many stainless steels and cast irons. Ti(C,N) + Al2O3 + Used Edge Detection (Chrome) M3 Chipbreaker: First choice for medium-rough machining and also the most versatile Seco chipbreaker. In most cases, it is the only chipbreaker needed. Offers the best useful life and best chipbreaking in a wide range of cutting data and workpiece materials. Suitable for precision forged and cast workpieces (NNS or Near Net Shape workpieces) as regards both chip control and edge strength. Indicative machining range: f = 0,15-0,50 mm/rev, ap = 0,5-5,0 mm.

Our FREE SHIPPING offer applies to the noted locations within New Zealand only. For international delivery, please Contact Us to discuss your requirements.

Principally intended for machining cast iron and hardened steel. Also suitable for aluminium and other non-ferrous materials. -F2 Chipbreaker - A reliable semi-finishing to medium roughing chipbreaker ensuring safe chip flow. Suitable for medium cuts in steel and stainless steels application including boring. Indicative machining range: f = 0,12–0,60 mm/rev, ap = 0,2–4,0 mm.

Principally intended for machining cast iron and hardened steel. Also suitable for aluminium and other non-ferrous materials. -F2 Chipbreaker - A reliable semi-finishing to medium roughing chipbreaker ensuring safe chip flow. Suitable for medium cuts in steel and stainless steels application including boring. Indicative machining range: f = 0,12–0,60 mm/rev, ap = 0,2–4,0 mm.

CP500 Grade: Tough micrograin grade intended for finishing to medium-roughing of stainless steels but with wide applicability for example in steels and aluminium alloys. Especially suitable in intermittent cuts. (Ti,Al)N + TiN F1 Chipbreaker: A versatile chipbreaker for positive inserts. Positive geometry with sharp cutting edge gives easy-cutting properties. Suitable for high feed rates at fine depths of cut on precision forgings and castings. Machining range: f = 0,1–0,5 mm/rev, ap = 0,2–3,0 mm. Machining in bar automatics, for instance: f = 0,08–0,25 mm/rev, ap = 1–3 mm.

Insertclearance angle

ISOinsertnomenclature pdf

"Maintenance people and buyers alike find drill point styles confusing,” says Atlantic’s Customer Service Manager, Tony Orvis, who’s been in the fastener business for 26 years.

Principally intended for machining cast iron and hardened steel. Also suitable for aluminium and other non-ferrous materials. -F2 Chipbreaker - A reliable semi-finishing to medium roughing chipbreaker ensuring safe chip flow. Suitable for medium cuts in steel and stainless steels application including boring. Indicative machining range: f = 0,12–0,60 mm/rev, ap = 0,2–4,0 mm.

TP2501: VERSATILE PRODUCTIVITY. Where versatility is needed and working conditions may not be perfect, TP2501 is the first choice for maximising manufacturing output under most varying productivity, cutting data and workpiece material requirements.An estimated 25% of steel turning applications feature working conditions that demand TP2501’s grade design and properties. TP2501 Grade: Duratomic® technology coated grade. Designed with high wear resistance and edge strength applicable in a wide range of turning applications in steels as well as many stainless steels and cast irons. Ti(C,N) + Al2O3 + Used Edge Detection (Chrome) M3 Chipbreaker: First choice for medium-rough machining and also the most versatile Seco chipbreaker. In most cases, it is the only chipbreaker needed. Offers the best useful life and best chipbreaking in a wide range of cutting data and workpiece materials. Suitable for precision forged and cast workpieces (NNS or Near Net Shape workpieces) as regards both chip control and edge strength. Indicative machining range: f = 0,15-0,50 mm/rev, ap = 0,5-5,0 mm.

Most products will be shipped to your nominated address by tracked courier. Our preferred courier company is New Zealand Couriers, however, we may have to use other freight companies from time to time based on an items size, configuration or dangerous goods requirements. Trade Tools cannot be held accountable for delivery times once items have been dispatched.

TP2501: VERSATILE PRODUCTIVITY. Where versatility is needed and working conditions may not be perfect, TP2501 is the first choice for maximising manufacturing output under most varying productivity, cutting data and workpiece material requirements.An estimated 25% of steel turning applications feature working conditions that demand TP2501’s grade design and properties. TP2501 Grade: Duratomic® technology coated grade. Designed with high wear resistance and edge strength applicable in a wide range of turning applications in steels as well as many stainless steels and cast irons. Ti(C,N) + Al2O3 + Used Edge Detection (Chrome) M3 Chipbreaker: First choice for medium-rough machining and also the most versatile Seco chipbreaker. In most cases, it is the only chipbreaker needed. Offers the best useful life and best chipbreaking in a wide range of cutting data and workpiece materials. Suitable for precision forged and cast workpieces (NNS or Near Net Shape workpieces) as regards both chip control and edge strength. Indicative machining range: f = 0,15-0,50 mm/rev, ap = 0,5-5,0 mm.

Features and Benefits Solid carbide is extremely heat-resistant and used for high speed applications on cast iron, nonferrous materials, plastics and other tough-to-machine materials. Specs Insert Style RCMT Insert Size 1606M0 Material Carbide Thickness (Inch) 1/4 Thickness (Decimal Inch) 0.2500 Inscribed Circle (mm) 16.00 Manufacturer's Grade TP3501 Coating TiCN/Al2O3 Material Grade C4/C5 Chip breaker M3 Rake Positive Relief Angle 7 Coating Process Duratomic Cutting Direction Neutral Insert Hand Neutral Insert Holding Method Screw FullRadius Yes MultiUseTool Yes Shape Round

0086-813-8127573

0086-813-8127573