Acritec Sink - Stainless - Undermount Single Bowl - 21005

The chemical element nickel is classed as a transition metal. In the 1750s nickel was discovered to be an element by Axel Cronstedt. Data Zone ...

High-carbon steel has a significantly higher carbon content than HSS and typically requires complex heat treatment processes like annealing, normalizing, tempering, and quenching to achieve the desired hardness and toughness.

Hinkley 40693 Poppy 4-lt 20" LED Semi-Flush Mount ... Poppy features clear seedy glass spheres that bubble out of refined, ribbed fitters to create a simple, yet ...

Complete Tool Store & Supplier Serving London, Ontario. At Contractor Cave, we're Londonindependent tool store, and your online order source for Canadian tools.

Both HSS and high-carbon steel have their own advantages and disadvantages, making them suitable for different industrial applications. When choosing the appropriate material, engineers need to consider the specific working conditions and performance requirements to make informed decisions.

Address. Dingmazhuang Village, Duqiao Town,, Jing County, Hengshui, Hebei,, China,Jingxian · City. Hengshui · Region. China · State/Province. Hebei · Zip/Postal ...

The price of high carbon steel is cheap, the hardness of high-speed steel is higher, and the wear resistance of high-speed steel is better. High speed steel is used for mold steel.

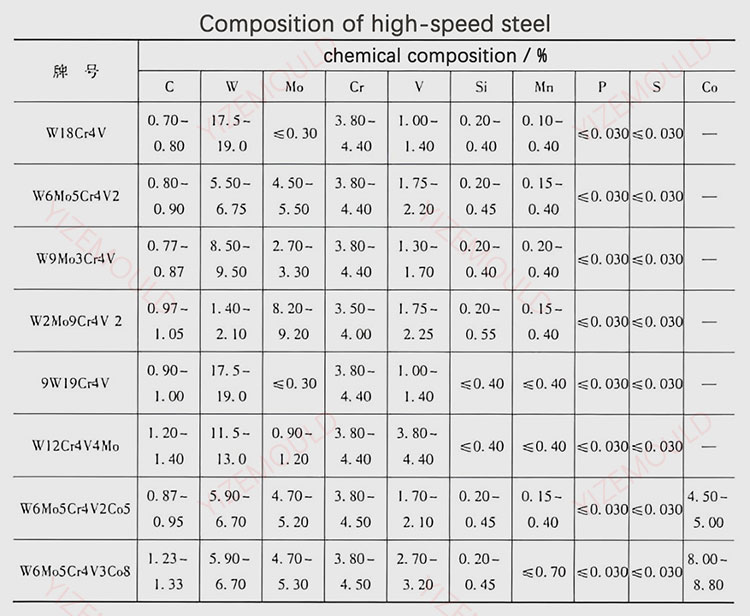

High-speed steel, also known as tool steel or white steel, is a high-carbon, high-alloy ledeburitic steel. It features high hardness, wear resistance, and heat resistance, making it ideal for complex thin-blade cutting tools and high-temperature bearings.

Description: Machining of Alloy Steels, Cast Iron,Ferrous Materials up to 50 HRc Stainless Steel, Titanium

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Carbide grinding (13) carbide questions and answers (21) Carbide Wire EDM (12) tungsten carbide (41) tungsten carbide bushing (12) Tungsten Carbide Punches (13)

V Puppo · 2017 · 27 — Alternative rituals avoid genital cutting and involve educating girls about family life and women's roles, exchange of gifts, celebration, and a public ...

Size, #6. Tap Type, Plug. Bit Decimal, 0.1380. Overall Length, 2. Thread Length, 11/16. Material, High Speed Steel. Origin, Domestic. Weight, 0.009, ...

S Ahmed · 2024 · 13 — Elastic impression materials are commonly used in the traditional approach to replicate anatomical structures while indirectly fabricating ...

The price of high carbon steel is cheap, the hardness of high-speed steel is higher, and the wear resistance of high-speed steel is better. High speed steel is used for […]

HSS, with its superior hardness, toughness, and wear resistance, is primarily used for cutting tools, mold steel, and high-speed bearings, such as drills and milling cutters. High-carbon steel, on the other hand, is commonly used for manufacturing springs and wear-resistant parts.

High-carbon steel contains a higher carbon content, resulting in high strength and hardness after heat treatment. It is suitable for manufacturing springs and wear-resistant parts, but its weldability and cold plastic deformation ability are relatively poor.

We accept Visa, MasterCard, and American Express. Copyright HTC Tool-Cutter Manufacturing ©2024.

High-carbon steel is relatively common and affordable. In contrast, HSS is more expensive due to its specialized properties and is typically used in more demanding and professional industrial applications.

In modern industrial production, material selection plays a crucial role in determining product performance. High-speed steel (HSS) and high-carbon steel, both widely used in tool manufacturing, exhibit distinct characteristics and applications. Let’s delve into their properties, applications, hardness, wear resistance, price, and advantages and disadvantages.

At CNC Intelligence, the goal isn't just to recover what's lost but to restore the sense of security that comes with it. They understand the personal toll that ...

HSS is rich in alloying elements such as tungsten, molybdenum, and chromium. It undergoes specific heat treatment processes like high-temperature annealing, quenching, and high-temperature tempering to achieve its superior properties.

0086-813-8127573

0086-813-8127573