Alcoa -- Home - aluminum mills in the united states

FR4material machining

Here's your comprehensive guide to Feeds and Speeds for Wood, together with Tips and Techniques that are specific to cutting wood on a CNC Machine.

Machining G10speeds and feeds

One method of producing CFRP parts is by layering sheets of carbon fiber cloth into a mold in the shape of the final product. The alignment and weave of the ...

At Upland Fab, we make communication a top priority. We provide consistent, reliable communication, with a single point of contact throughout your whole project, to keep you up to date as your project progresses. We stay in touch every step of the way.

Garoliteg10 material machining

Experience the iconic beauty of our Mission Bay resort! Surrounded by a secluded beach and lush gardens, the Bahia Resort Hotel is your ultimate destination ...

G10 material machiningpdf

As noted, G10 fiberglass is very difficult to machine with precision. Upland Fab uses advanced multi-axis machining systems with special tools that enable us to deliver G10 fiberglass parts with exceptional precision, tight tolerances, and perfect repeatability. Our CNC machining technology allows us to manufacture parts with minimal handling and fixturing requirements; in many cases, even highly complex parts can be completed in a single operation.

G10 material machiningcost

A type of phenolic laminate, FR4 glass epoxy is produced by applying heat and pressure to multiple layers of disparate specialty materials which have been impregnated with synthetic thermosetting resins. The heat and pressure polymerizes the individual layers into a single, laminated material.

G10 materialproperties

Speeds & Feeds ; End Mill Diameter, in ; Spindle Speed, RPM, Machine Max ; Cutting Edges. Chip Load ; Chip Load, in/flute ; Feed Rate, ipm.

Keyway tools · Show product · Keyway tools Wanco · More info · Show product · Loose broaches for sleeves · More info · Show product · Keyway tools · More info.

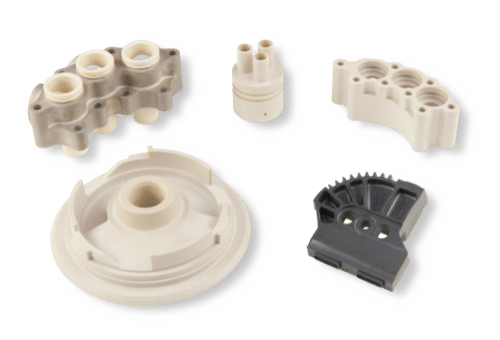

G10 fiberglass and FR4 epoxy are well suited to an extensive range of industrial productions. Common uses include medical manufacturing, defense productions, and much more.

We use DPD/MBD processes (Digital Product Definition/Model-Based Definition) that enable us to work directly from your CAD models. By working straight from your digital design files, we can eliminate machining errors and improve accuracy. The end result? More precise and cost-effective parts.

Machining G10safety

Hamakua Macadamia Nut Company – Home of the Big Island's Famous Hawaiian Macadamia Nuts · Shopping, Culture, Food / By Stefan Verbano. There simply is no better ...

It provides easy-to-use machining information, including speed and feed calculators, material removal rates and more. ... Face Milling; Solid Milling.

Upland Fab has been providing top-flight plastics and composite machining in Southern California since 1970. Contact us for more information or get a quote on G10/FR4 electrical grade epoxy resin machining for your project.

G10 material machiningprice

CS Tool Specializes in the design and manufacture of plastic injection molds and compression molds for the automotive and consumer goods industries.

Are you looking for another material? We have the ability to machine many different materials take a look below at some of the other plastics we work with.

z Organized according to turning insert shape. (Refer to the index on ... chart below. Multiply the coefficient value by the recommended cutting speed ...

Micro 100's thread relief cutters are designed for milling thread relief at the bottom of a thread, eliminating burrs and partial threads.

Like other phenolic laminates, G10/FR4 electrical grade epoxy resin is extremely strong and stiff. FR4 glass fabric also exhibits a low coefficient of thermal expansion and outstanding electrical properties, making it an ideal material for electronic and electromechanical components. It is flame retardant and, with very low moisture absorption, is well-suited to use in high-humidity environments, and one of our most trusted laminate products we work with.

0086-813-8127573

0086-813-8127573