All About Milling in Machining - how to mill small metal parts

As I moved the castings, each was weighed with a bathroom scale. The scale is accurate +/- 5% when compared to my beam style bathroom scale.

72195- W/O CONTRAST. 72197- W/O & W/ CONTRAST. CPT CODES for MRI SCANS. Murray Center. 5323 South Woodrow Street. Murray, UT 84107 / Suite 100. P (801) 713-0600 ...

Ten years ago I bought my new Enco RF-30 Mill/Drill (model 105-1110). My friend and I used a half-ton pick-up truck to move it from the local Enco warehouse to my garage. Then an engine hoist was used to transfer the machine from the truck bed to the garage floor. Ah, that was the easy part. The final destination for my new toy was in the basement. I had to move through our kitchen (without damaging the floor) and down the stairs (without having them collapse). It took a lot of planning but all went well. I did have to re-support the stairs, which took a fair amount of time. I then used the engine hoist to lift up the mill while I slid the support frame under it. Most people who own these mill/drills have a similar story.

Metal; Nonferrous Metal; Nickel Alloy; Pure Element. Material Notes: This ... Physical Properties, Metric, English, Comments. Density, 8.88 g/cc, 0.321 lb/in³.

A compromise would be to get one of the inexpensive "hobby" sets, and, when (inevitably) one or two of the "more often used" sizes breaks, pick up a pack of ten "industrial" bits as replacements.

I use micro carbide drill bits. All my bits have 1/8" shanks and chuck right in my moto-tool. I use a 4.8v re-chargeable moto-tool. You CAN NOT hand drill with these. They are super sharp but snap in a heartbeat. I use the slowest speed and make sure the bit goes in nice and straight. Any angle or twisting and they will snap. They will do most brass and copper but you have to be careful when they are about to break through. They will catch very quickly and snap if you are not careful. It takes some practice with these bits but once you know what they can and can't do and the materials you can and can't use them on you won't regret it. They never wear out and you can do some incredibly precise drilling. My go to for these bits is Drillbitcity.com.

This dolly was designed to freely roll around the floor yet could be locked onto a track placed on the stairs. A winch was used to pull the dolly up the stairs. All castings except the saddle rode the dolly up the stairs. A handcart was used on all but the base casting to move the part into the garage. The base casting stayed on the dolly until it reached the door into the garage. Then the casting was slid down a wooden ramp and onto blocks on the floor. The dolly was again employed to move the base to the re-assembly area.

The spindle pulley, idler pulley assembly, and belt shroud were removed first. This shroud is relatively delicate and large. It would have made handling the head difficult plus makes removing the motor a bit awkward.

There are some things it never pays to scrimp on, and small drill bits is one of them. This will include many drill bits sold to hobbyists as a set. A properly ground drill bit requires precision manufacture, necessary for a bit that will cut well and evenly from both cutting lips and bore a straight, clean hole. I buy machine shop quality bits in packages of 10 or 12 from jobber shops that sell tools for industrial use. Places such as Acklands-Grainger or McMaster-Carr, or many other similar shops sell them. Most recognised name brands are good for model use, Dormer and Greenlee come to mind, but there are many. The difference in cutting performance between a proper bit and cheap hobby junk is night & day, and there is nothing more frustrating then doing some precision micro-drilling on a small, delicate piece with a cheap bit. They cost much more, but for anyone doing scratchbuilding, they are worth it. If you are only using them for pinning, then you could get away with buying only one or two sizes that correspond with the size pins you like to use.

Re-assembly was straightforward except for getting the head back on the column. I did not want to try to hold the head in my arms and fish it back on the column along with the rack. Instead I placed the column horizontally and facing down. It rested on two pieces of scrap wood. The head was placed with the back face of the casting on the floor. Next the rack was set into its keyway and engaged with the drive gear. Since the rack is resting on its side, gravity does not try to pull it out. This is one less thing to fight. If the column were vertical, then the rack would tend to fall out of its keyway at every opportunity. Using a slight rocking motion on the head, it was easy to slide the column through the lower opening of the head and up to the start of the upper opening. Any misalignment between column and head becomes evident by looking into the upper opening from the top. Thin wood shims can then be used to adjust the vertical position of the column. Horizontal alignment is achieved with a slight side to side twist of the head casting.

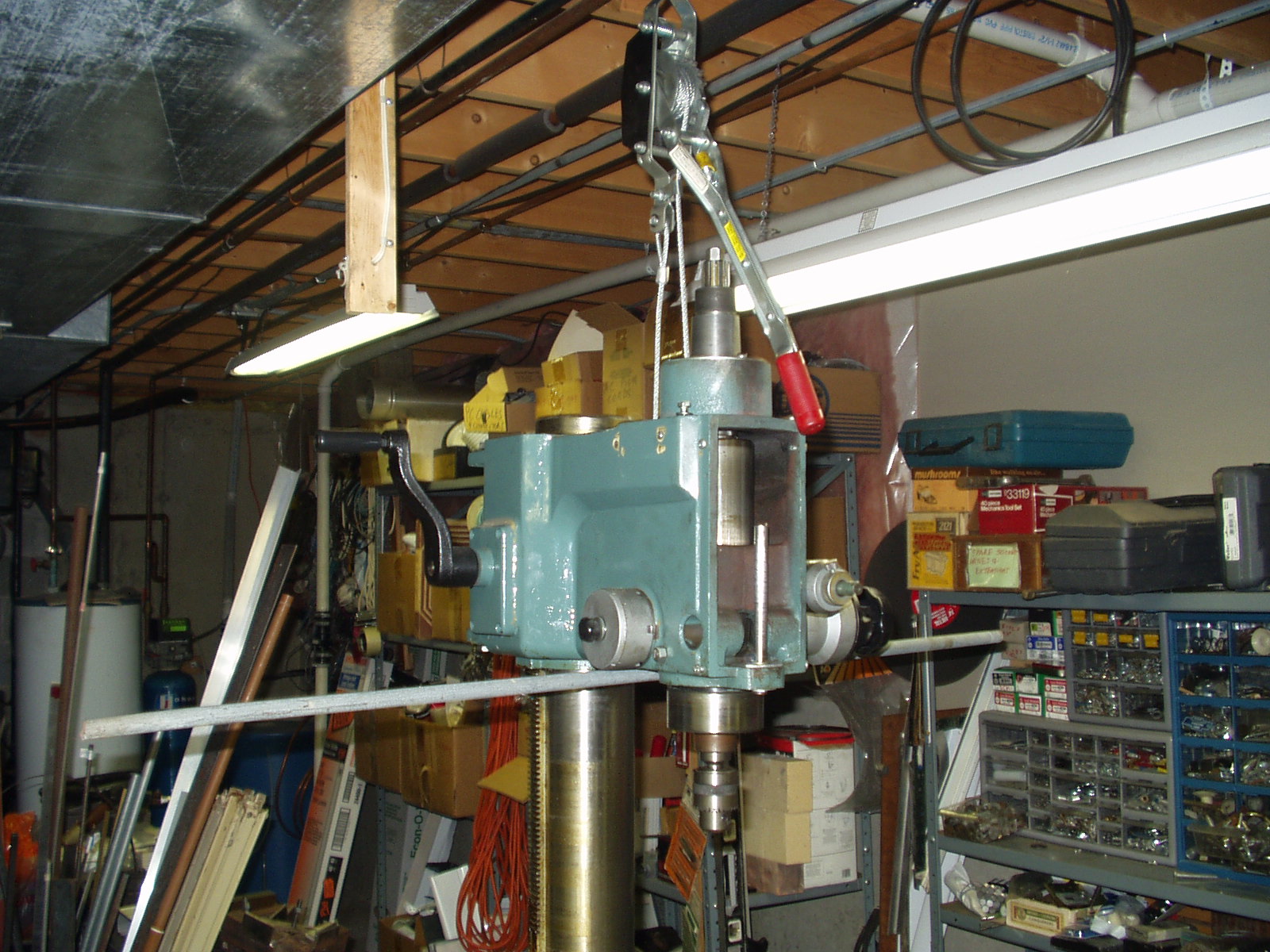

Next came the head. It was tempting to leave the column and head as one piece but the combined weight was more than I could handle. Others had warned me that putting the head back on the column would be difficult. My decision was to remove the head and deal with re-assembly later. I bolted a length of welded chain to the rafter and connected my 2000-pound capacity come-along. It is not wise to use it in this orientation but given the weight of these separate pieces, I felt it was safe enough (do this at your own risk). With the top cap removed from the column, the head was raised to the top and then lifted off.

Oct 22, 2024 — 7 A machinist creates a solid steel part for a wind turbine engine The part has a volume of 1015 cubic centimeters Steel can be purchased for ...

I tried installing pins in some side view mirrors over the weekend. I have a set in a blue plastic case, and I couldn't get them to drill at all. Even starting a spot by twirling an xacto blade didn't help.

Im now 10 years older and maybe a little wiser. It is time to move my mill/drill back into the garage. Is there an easier way to move it this time? After living with this machine for a decade, Ive learned how it comes apart and how to put it back together. Furthermore, gravity will be against me on this trip. So instead of trying to move the machine as a single unit, I took it all apart, moved the pieces, and then reassembled the mill/drill in the garage.

A compromise would be to get one of the inexpensive "hobby" sets, and, when (inevitably) one or two of the "more often used" sizes breaks, pick up a pack of ten "industrial" bits as replacements.

Such was the success of the first bonded medical manifold that they have now become a standard across the industry. Carville have produced in excess of ...

This casting is too heavy for me to safely lift so I used straps and my come-along to do the work. A slight tension was placed on the straps before I unbolted the casting from the support table. Lag bolts that secured the support table to the floor were then removed. The casting was now lifted up about 1 inch making it easy to slide the support table aside. The casting was then lowered onto a special built dolly and secured with the straps.

Only small drill bits i have is from tamiya. I don't really use drill bits that much unless it's a kit where i need to drill some holes or something.

You may find these weights useful even if you do not have this particular mill/drill. The percentage of total figures should be close if your mill has the same basic shape as mine.

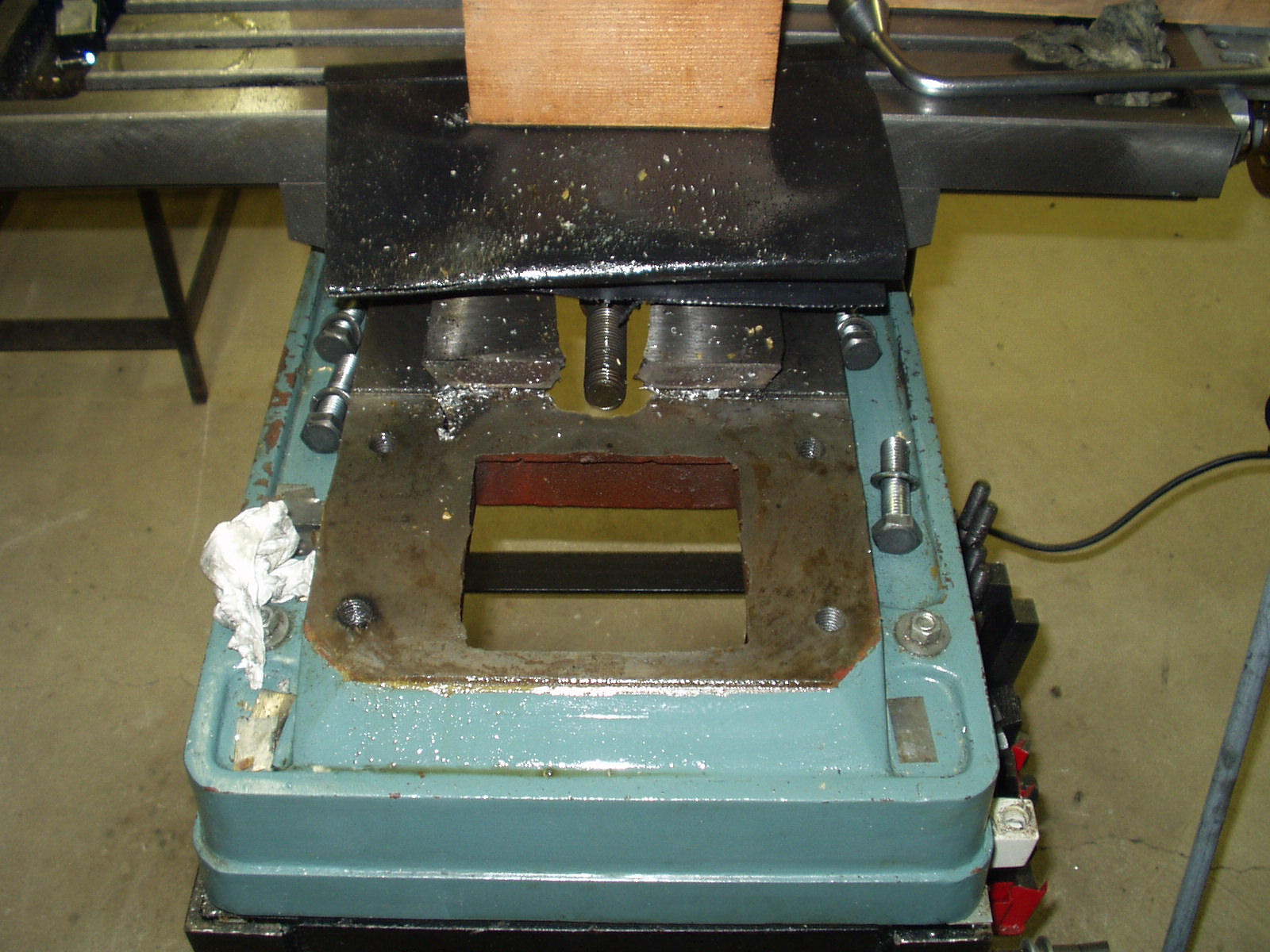

The column was next. Four bolts hold it to the base casting. Then it was a matter of lifting the column up and walking it over to the workbench. Here is the view of the base with the column removed but the table still attached. The cross feed lead screw is visible in the center of the picture. You may also notice a shim in the lower right corner. Adding shims between the column and base casting is how I tram the head. One of the column bolts can be seen just above this shim.

Carbide for Metallurgy. Calcium carbide is a powerful and effective chemical reducing agent, and can also be used as a source of energy. Nowhere is this more ...

Kyle, this is a subject that comes up every once in a while. Please read through the thread below as it pretty much covers all the answers.

The head was lowered onto the wood making the operation well controlled and smooth. The motor was then carried to the workbench.

Normally, I would agree. I sometimes do this with other items when the buy-in cost of quality is too much to bear at one time. But, with low-quality small drill bits, the cutting quality is what suffers, creating bores that are oversized, crooked, off-centre, bell-mouthed, and sloppy, and requiring many more turns of the pin vise to make the hole. When doing small, precision drilling, the quality of the work will suffer, as will the enjoyment of the task. Also, some cheap drill bits are much less breakable than quality bits, some having the molecular integrity of a over-cooked noodle. I have even bent them without breaking.

Piccolo Simple System small flute or fife, 6 key, France, c1890, anonymous, silver and cocuswood. Missing cap, key, pad, crack in barrel.

The table comes off next. This is accomplished by first removing one hand wheel. Next unbolt the lead screw bearing supports. The lead screw can then be rotated until it comes out.

I have a set from Micro-Mark. They're not cheap but they work great. Can't remember the brand right now but they come in a round domed case with about 15-20 bits.

Dec 7, 2022 — how to identify your turning insert · Making sense of the ANSI (American National Standards Institute) insert code system · Insert Shape (CNMG332).

In order to remove the saddle, start by unbolting the cross feed bearing support. Then unscrew the cross feed lead screw. The cross feed nut must then be unbolted. Then the gib is removed and the saddle slides right off the back.

I next removed the motor and related switch and wiring. It is not very heavy but I did not want to have to catch it when the last hinge bolt was removed. A shop stool piled with scrap lumber held the motor as I removed the hinge bolts.

I first raised the base casting up about 2" from the floor on blocks. Two sets of blocks were used, supporting the front and back bottom edges of the casting. Then I slid the scale under one edge, replacing the support provided by one set of blocks. The casting was again level. I took a reading, S1, from the scale. The procedure was repeated on the opposite side to measure S2. The total weight is then just the sum of these two readings. Furthermore, if we define the distance between support points as L", then it can be shown that the center of gravity is X" from the edge raised while performing the S1 weighing:

Best small drill bits I have encountered is from Drill Bits Unlimited. The ones I get are 1/8" shank but are anywhere from #80 to #60 in size. #71 is about common pin size and is great for drilling holes for securing small parts. These drills are super sharp but are quite brittle if not used carefully. Still, I recommend them highly. I use them in a pin vise as well as a small drill press.

You can post now and register later. If you have an account, sign in now to post with your account. Note: Your post will require moderator approval before it will be visible.

The first step was to take pictures of the mill/drill from every possible angle. Many close-up shots were also taken. This was my insurance policy against having a "senior moment" that might prevent me from reassembling the machine correctly.

Once the column emerges from the head, I re-supported the end with scrap wood and removed the piece in the way of the head motion. The head is then slid down to the bottom of the column and secured in place with its locking bolts. It sure is nice not to fight gravity.

The "most often used" sizes ought to have dedicated pin vises or mandrels; that is, have one that is used only with that size bit. The "hobby" pin vises are usually made of aluminum, if the opening has "crushed" around a larger bit, then it will have some "slop" when used with a smaller bit later on.

Since the casting is symmetric, the center of gravity left to right must be in the center. Knowing the center of gravitys horizontal position is useful when you start to move the casting. The casting can be thought of as a force equal to the total weight concentrated at the center of gravity. If, for example, the center of gravity ends up overhanging a dolly, expect it to flip over at the worst possible time. A variation of this procedure can be used to find the center of gravitys vertical position. Just rotate the casting 90 degrees so the base goes from horizontal to vertical.

The set I have used for years, along with a few replacements bits, came from a locale Hobby Shop and there is no name displayed on the case. The base is a round flat plastic black in color and just says Drill Stand in the center and the domed top is clear. The sizes range from #80 or 0135 thru # 61 035 in size. I also have another universal drill with some larger sizes in the handle that I got at a Hobby Lobby and I still see then being offered when I have visited. I agree with Bainford and TonyK that this is an area you should focus on quality over price. I have found them indispensable for attaching small parts and reinforcing many components in my builds.

Best small drill bits I have encountered is from Drill Bits Unlimited. The ones I get are 1/8" shank but are anywhere from #80 to #60 in size. #71 is about common pin size and is great for drilling holes for securing small parts. These drills are super sharp but are quite brittle if not used carefully. Still, I recommend them highly. I use them in a pin vise as well as a small drill press.

Note the long cross bar. My come-along cable ran through the cavity in front of the column and hooked onto this cross bar. The bar is too long to slip out and provides plenty of leverage for maneuvering. Once the head was free of the column, it was a matter of moving it away from the rest of the mill/drill and onto the mills table. I was then able to carry it to the workbench.

Deburring external discount chamfer tool bunnings, CONQUER Tools Deburring External Chamfer Tool Premium Tungsten discount.

Sep 21, 2024 — Collets or collet chucks are a type of chuck that holds a tool or workpiece in place. They come in different shapes and sizes and are used for different ...

For austenitic steels, (e.g. 304, 1.4301), the depth of cut must however always undercut the induced work hardened layer, so increase in speed must be carefully ...

A few words about weighing the mill are in order. All castings except the base were placed directly on the scale. The base was weighed using the following procedure.

Exactly. I bought a few sets years ago, multiples of the sizes that I use the most. I originally bought some at Harbor Freight almost 20 years ago, & have bought random sizes over the years to replace broken ones & fill in the missing sizes. I use them by hand, no pin vice. I have broken some, but it teaches you to be more careful.

Casting name Weight, lbs. % of total head 110 22 column 85 17 saddle 30 6 table 80 16 base 100 20 motor 45 9 Misc. parts 50 10 total 500 100

0086-813-8127573

0086-813-8127573