Alti Financial About Us | - alti in

I don't work to micron accuracy, but I do like to understand what I'm trying to do. Understanding the theory to a reasonable degree of accuracy eliminates it as a source of error. Once you have numbers they can be adjusted to whatever tolerance is needed, or accepted. Misunderstanding the basics and making incorrect approximations just leads to sloppy work – possibly in more than one sense.

Acmethread depth formula

I forgot to mention too that if using a standard V tool bit, it's best to put a small radius on the tip by rubbing it on the bench oil stone etc. Not because of the thread form that results but because it helps pevent the tip of the tool from chipping off.

Funny. I've been using the "incorrect" method of slightly undersized OD and .6134 x Pitch at work and at home for about 45 years now without problem. Like I said, trying to duplicate the exact ISO thread form drawings is overkill in the home workshop, and in the professional machine shop most of the time. As Tubal Cain points out, you only need about 65 per cent thread engagement to have about 95 per cent of maximum thread strength. I believe it's best for a beginner to stick with the tried and true .6134 x P formula that has served generations of machinists well.

Sanding Station Tool room humour Horizontal mill cutter runout Horizontal Mill Identification Scroll Saw Blades for Steel Tap alignment in the mill and lathe? Another One Gone! Spring material advice needed Trapezoidal tap drill size ? Nominal sizes?

Base: For best results we highly recommend including the "Xpert Tool Base." This is optional but highly recommended and in most cases necessary.

Metric thread depth formulain mm

For example take a 12×1.25 thread. The nominal OD is 12mm and the fundamental deviation for a 6g fit is -0.028 giving a maximum major diameter of 11.972mm. There is then a machining tolerance of a maximum of -0.212mm. A 12×1 thread is not standard, so you'll have to work out the numbers yourself.

If it's important because the thread has to be cut on an existing part that can't be replaced, practice on something else until you get good results!

Just kept trying it as I got close until I got a nice fit. When I said fairly important it was a ball screw for converting my SX3 to CNC.

For the depth of thread use the table provided but note that if the threading tool does not have the stated nose radius you may have to adjust the depth of cut to suit.

Thanks for the info but i have bought 12×1 locking nuts and it is mentioned in tables so it seems standard at first glance.

That;s the best way: see how it goes. Try a few test pieces first and get the feel of things before attacking a real job. And you can always use a die to finish off your thread if you feel so inclined. Usually gives a good finish with minimal time spent on final finishing.

With the 0.6134 x pitch I can now see that this will indeed cut down to the Minor core diameter in this case 10.77 so that's that solved also.

Just kept trying it as I got close until I got a nice fit. When I said fairly important it was a ball screw for converting my SX3 to CNC.

Metric thread depth formulain inches

Arbor Press: An arbor press is required to use these tools. Arbor presses are not sold by Xpert Sign Tools. Visit our page on Arbor Presses for links to presses that are available on Amazon.

A 12×1 metric thread is not standard in the sense that it isn't in the coarse or fine series. It appears in the constant pitch series, for which hardware, and taps and dies may be available, or not, as the case may be.

Metric thread depth formulapdf

When screwcutting in the real world (ie home workshop) it is best not to try to hold exactly to the ISO thread form drawings such as those you refer too. They are far too exacting for practical home use.

In my workshop, I'm usually with Hopper. I mostly make threads where the only requirement is they have to fit together. The threads don't have to maximise strength or to minimise backlash. I don't bother reducing the rod slightly below nominal size, I use an ordinary 60 degree cutter, and I don't worry about getting the thread form perfect. I cut down towards theoretical depth and then test with a nut, only going deeper if the nut won't go on or jams. I usually run a file over the crests to flatten them and remove any excess diameter that may have squeezed up during cutting. Rough work in terms of precision and accuracy but plenty good enough for 95% of what I do.

Am I correct in saying that to cut a 12x1mm thread I have to turn the bar down to 11.8mm? I'm asking because in The Model Engineers Handbook by Tubal Cain he shows a drawing and I can just about see it says 0.1P for the amount of thread crest that is taken off.

If you are threading to use a nut then best have that to hand and trial fit when approaching the depth of thread, it's easy to go to deep.

The ultimate tool for rounding corners on aluminum, brass, magnetic, copper, sheet metal, Dibond®, omega board, coroplast, posterboard and much, much more.

Run a file down the top of the thread groove to remove the burr and round off the crest a bit. The corner of a common flat file works well for this.

Search for: Home › Forums › Beginners questions › Topics Viewing 25 topics - 1 through 25 (of 25 total) Topic Voices Posts Last Post Sanding Station Started by: Michael Gilligan in: Workshop Tools and Tooling 9 14 10 November 2024 at 23:31 Michael Gilligan Tool room humour 1 2 Started by: Ian Johnson 1 in: The Tea Room 19 28 10 November 2024 at 22:10 Michael Gilligan Horizontal mill cutter runout Started by: Mick Bailey in: Manual machine tools 11 12 10 November 2024 at 22:05 RobCox Horizontal Mill Identification Started by: Mike Freeman in: Workshop Tools and Tooling 3 3 10 November 2024 at 21:21 not done it yet Scroll Saw Blades for Steel Started by: James Alford in: Workshop Tools and Tooling 8 12 10 November 2024 at 17:57 James Alford Tap alignment in the mill and lathe? 1 2 Started by: Bo’sun in: Workshop Tools and Tooling 18 37 10 November 2024 at 17:54 Bo’sun Another One Gone! 1 2 Started by: Chris Crew in: The Tea Room 19 30 10 November 2024 at 14:27 John Haine Spring material advice needed Started by: old mart in: Materials 7 9 9 November 2024 at 21:05 old mart Trapezoidal tap drill size ? Started by: jim1956 in: Beginners questions 5 7 9 November 2024 at 18:47 jim1956 Nominal sizes? Started by: Bo’sun in: Workshop Tools and Tooling 6 8 9 November 2024 at 17:25 Bo’sun Estimated value of restored lathes Started by: harmond94 in: General Questions 9 9 9 November 2024 at 12:33 mgnbuk Anyone interested in sharing a space? Started by: harmond94 in: Help and Assistance! (Offered or Wanted) 1 1 9 November 2024 at 12:27 harmond94 a more unusual hobby shed find 1 2 Started by: pgk pgk in: The Tea Room 22 35 9 November 2024 at 12:17 Vic Myford 4-slot vertical slide & vice Started by: flatline in: Beginners questions 12 21 9 November 2024 at 10:43 Nicholas Farr Provenance Started by: Martin Kyte in: The Tea Room 2 2 9 November 2024 at 09:50 noel shelley Universal Machine Tool Started by: Vic in: The Tea Room 7 11 8 November 2024 at 16:42 Steam of Steel Boll Aero18 Drawings Started by: Clive Brown 1 in: I/C Engines 4 8 8 November 2024 at 15:44 JasonB Shipping deliveries – USA style – video Started by: Bazyle in: The Tea Room 5 6 8 November 2024 at 15:07 old fool Electromagnets (Split From Stuart Dynamo) 1 2 3 Started by: SillyOldDuffer in: Beginners questions 15 70 8 November 2024 at 13:39 duncan webster 1 Alternative to Bronze? Started by: Vic in: Materials 11 14 8 November 2024 at 11:01 peak4 Dull men Started by: old fool in: The Tea Room 7 12 8 November 2024 at 09:39 vic newey Motor Carbon Brushes Started by: David Deaville in: General Questions 8 15 8 November 2024 at 09:37 Howi Stuck Tich piston 1 2 Started by: Mark Salzedo 1 in: Beginners questions 14 37 7 November 2024 at 22:59 Mark Salzedo 1 Which steel for studs? Started by: John McCulla in: Materials 15 24 7 November 2024 at 22:54 noel shelley Another, What is it? Started by: Ian P in: The Tea Room 3 4 7 November 2024 at 20:57 Ian P Viewing 25 topics - 1 through 25 (of 25 total)

If 'fairly important' only means it has to fit together with moderate strength (60-70% of theortetical), Hopper is plenty good enough. But if the thread must be strong and/or a tight smooth fit best proceed as Andrew, or compromise with a die. Finally, if the part is safety critical – essential to holding a car's brakes together – then I'd recommend buying the right commercial part.

I normally use partial thread engagement for threading. However you only need the reduction on one half the combination. If it's on both then the thread engagement is a lot less. Since it is simple to produce a full depth external thread, but difficult for internal threads (especially when using taps) that's what I do. I cut external threads close to full depth and drill for internal threads to give the required engagement.

Collections: All Products , Corner Rounders

![]()

Vthread depth formula

Home › Forums › Beginners questions › Metric thread cutting in a lathe This topic has 35 replies, 16 voices, and was last updated 26 January 2019 at 00:22 by peak4. Viewing 25 posts - 1 through 25 (of 36 total) 1 2 → Author Posts 24 January 2019 at 22:36 #392836 BufferParticipant @buffer Hi Sorry for this basic question but I have only cut 1 thread in a lathe and now need to do something fairly important. I know how to set the tool the cross slide etc but my problem is more to do with lack of knowledge of threads. Am I correct in saying that to cut a 12x1mm thread I have to turn the bar down to 11.8mm? I'm asking because in The Model Engineers Handbook by Tubal Cain he shows a drawing and I can just about see it says 0.1P for the amount of thread crest that is taken off. Is it better to take this off the diameter before I start or does it not matter? I am thinking I should take it off before or I will end up not knowing if I should cut the thread deeper or take some of the diameter to get the nut to fit! Some advice would be great. One last question, How do I work out how deep I need to cut in order to get the thread properly formed. Is it simply 0.86mm as he seems to show what looks like 0.86P. Or does it have something to do with the Minor Core diameter that is listed in the tables, which in this case is shown as 10.77mm Sorry if this seems basic but I have always stayed well away from threading in the lathe through lack of knowledge but now I need to start doing some. Thanks for any help you can give Rich

Am I correct in saying that to cut a 12x1mm thread I have to turn the bar down to 11.8mm? I'm asking because in The Model Engineers Handbook by Tubal Cain he shows a drawing and I can just about see it says 0.1P for the amount of thread crest that is taken off.

Thread depthcalculator

Look again at the book and you will see as Andrew points out the "Major Diameter" is to the crest not the projected point that is "taken off". The 0.108P or H/8 is over and above the Major Diameter.

The major diameter for an external metric thread is nominally the diameter of the thread minus a fundamental deviation, and also a machining tolerance, both dependent upon the class of fit. You do not take off the truncation of the thread form, that is already built in. Incidentally the height of the crest truncation is H/8, where H is the theoretical sharp thread depth.

For practical work at home, yes make the outside diameter a few thou undersize so as to allow clearance on the thread tips. For a 12mm thread, I would turn the OD about .005" or 0.1mm undersize, or a little bit more. So 11.8mm is ok too. Yes, machine it down before you cut the thread.

You don't say what your job is but I think most amateurs aim to get the screw to fit the nut rather than to produce a theoretically correct thread form; by "fit" I mean on the flanks of the thread – as long as the crests and roots clear each other their precise dimension and form are less important.

Where thread strength and fit are both paramount – like the bolts that hold aircraft wings on – it's unlikely that a high-end fastener would be made by a cutting process. Rolled threads are considerably stronger that cut threads. Most commercial fasteners are rolled for cheapness, but the posh ones are made more carefully from better metal, finished by grinding, and inspected.

Sorry if this seems basic but I have always stayed well away from threading in the lathe through lack of knowledge but now I need to start doing some.

Plus one for Andrews last comment because it’s always best to try and achieve a high standard, I often use a thread mic for some work where it’s critical and I don’t have a callipers gauge. Most threads I cut I do truncate and I use both hand ground tools and full form tipped tools.

What's meant by 'fairly important' is the elephant in the room. It decides whether Andrew's answer is more appropriate than Hopper's.

This tool operates using any basic manual arbor press, is spring loaded, and will shear up to .080" aluminum and 6mm Dibond, sentra, sheet metal, and even magnetic material. *

How to calculatethread depthby turns

Having said that for many things in the home workshop as long as it fits together and does what you need then it serves its purpose!

Some suppliers call it extra fine; Machinery's Handbook says constant pitch so that's what I'll use. I stopped purchasing from TT a good few years ago, for several reasons.

No set-up needed —no measuring, marking or sanding individual corners. Create one of four different radii options with one simple punch!

Is it better to take this off the diameter before I start or does it not matter? I am thinking I should take it off before or I will end up not knowing if I should cut the thread deeper or take some of the diameter to get the nut to fit! Some advice would be great.

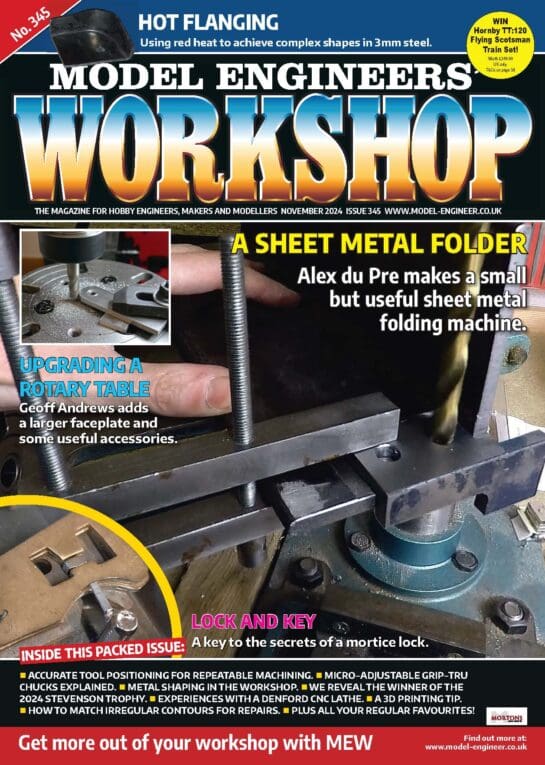

Model Engineer and Model Engineers' Workshop are leading magazines for modellers, with reputations for bringing you the best tips, tricks, and inspiration from the model engineering world. From miniature steam locomotives to clocks and tools, get the most out of your hobby with Model Engineer and Model Engineer's Workshop.

![]()

When you get to the stage where you can just about make out the lines on a 6" rule,precision takes on a whole new meaning !!

If using aground tool or partial profile you may need to run a file down the crests as you get close to remove burrs so that they do not contact the nut first and give a false sense of a good fit. Also depth of cut will depend on the type of cutter as a pointed one will need to go in further than one with the correct radius on the end.

Metric thread depthchart

Last time I bought a m12 x 1 nut for a ballscrew it was left hand thread. Glad you didn't find that out after making one.

One last question, How do I work out how deep I need to cut in order to get the thread properly formed. Is it simply 0.86mm as he seems to show what looks like 0.86P. Or does it have something to do with the Minor Core diameter that is listed in the tables, which in this case is shown as 10.77mm

Some at least of the answers to your questions are to be found in Martin Cleeve's "Screwcutting in the Lathe" (no 3 in the Workshop Practice Series).

That's the theory. In practice I start with the work at the nominal diameter or very slightly above, in this case 12mm. I then cut to the calculated thread depth and check final fit with a mating thread. I find that one needs to cut a thou or two deeper than the theory in most cases. For standard thread forms I use full form threading inserts. That way all the crest and root shapes are taken care of.

Turning the bar before threading will ensure you have a better chance of a straight thread. I am not certain about the .2mm undersize but the author was far wiser than me so you could follow his advice before threading, although you may find the OD has grown during the threading process.

As said already, final sizing is by trial fitting a nut of known quality. (Cheap hardware store nuts are a notoriously loose fit so you might want to make your own test piece using a tap if needed.)

It would also be helpful to know something about your lathe and tooling: single point threading techniques are different from those applicable to insert tooling.

Occasionally I need a better fit. My preferred approach is to rough out about 60% of the thread with a lathe and then finish off with a die. The die puts a more accurate finish and profile on the thread. If I don't have a die of the right size, and the thread needs to be a good fit for strength or backlash, then I use carbide index thread tools and take much more care with dimensions and finish. This is much more like Andrew's approach. As I'm not skilful and have poor concentration, about 1 in 4 of my 'best effort' carbide cut threads are rejects due to small flaws.

Visual comparison with an M6 machine screw is a useful tool too. The thread form is the same but yours is just 6mm greater in diameter so if the M6 thread is measured as 5.9mm diameter, cut your 12mm master 11.9mm. You can also put the M6 in your chuck, advance the threading tool up to it so it sits fully into the existing thread, note the slide position reading and then add 3mm to the reading as your finished depth position when cutting the bigger version. Another useful tip is use a jewellers magnifying loupe to look closely at the thread to check it looks like your M6 version. Coincidentally, I've been cutting 12mm x1mm threads this week.

0086-813-8127573

0086-813-8127573