Alti In Desk Cable Cover | Office Furniture | Auckland NZ - alti in

Do not want to buy a motor and loose parts feeder but still have to prep loose parts? We have tape guides suitable for loose components that facilitate feeding low volumes of loose parts: More info PDF

Crosscutting

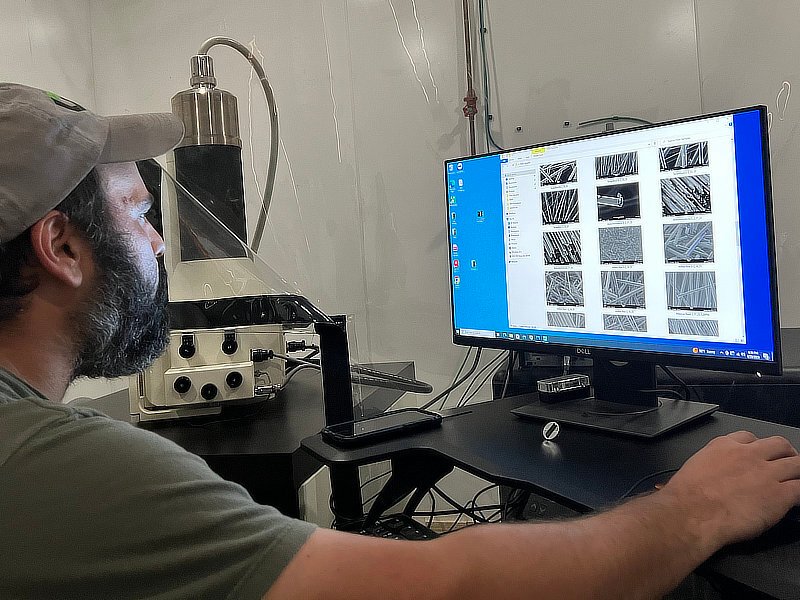

When we accept your carbon fiber, none of it will go into landfills. We recycle 100% so you can proudly say that you do too.

CFR’s patented low emissions technology solution uses over 90% less energy than virgin carbon fiber and produces the cleanest recycled carbon fiber in the industry.

The TP6-D cuts & bends axial components as the regular TP6, with the difference that this machine has Delrin instead of metal inner discs so it will not mark the surface of the leads of the components when it bends them. This is important when working with very small and delicate components and for Military applications. 20.OL11 Standard machine 20.OL12 Reinforced machine Minimum cutting length "B" = 4.6mm and maximum lead diameter "d" = 0.8mm TP6/D-M A Motor-98 can be connected to the manual TP6/D machine. ALL TP6 Spec PDF TP6/D Spec PDF

Axialcut imaging

Index | Accessories | Economy Machines | Counters | PCB Depanelers | Terminal Machine | Pin Machine | Hand Tools | BGA Reballer | Feeders & Special Machines | Flat Cable Separator | Parts Lists

Axial Machines TP6 | TP6/D | TP6/97 | TP6/PR-B | TP6/PR-F | TP6/V | TP6/V-PR | TP6/S

Video of the CS10. Do not want to buy a motor and loose parts feeder but still have to prep loose parts? We have tape guides suitable for loose components that facilitate feeding low volumes of loose parts: More info PDF

Axialplane

BODY GUIDES When it is necessary to bend very close to the body and the components are not taped with the component body properly centered, the body guides feed the tape by keeping the component body centered at all times. The body guides are used instead of the tape guides. More Body Guides info PDF We also offer Hand Tools for Cut, Form or Cut & Form.

STANDARD LEAD Ã: 1 â 1,3mm 40.OL21 Z=3,1mmm 40.OL31 Z=3,9mm 40.OL24 Z=5mm REINFORCED LEAD Ã: 1 â 1,4mm 40.OL22 Z=3,1mm 40.OL32 Z=3,9mm 40.OL25 Z=5mm NOTE: With the TP6/PR-B it is possible to eliminate the stand-off form substituting the cutting/forming wheels with "only cutting wheels" TP6/PR-B/M A Motor-98 can be connected to the manual TP6/PR-B machine. TP6/PR-B Specs PDF

TP6/PR-B Cutting, bending and forming machine for axial components. The form obtained is a Stand-off which keeps the body of the component off the board. No dies are required. Large diameter components only: .039-.055" (1-1.4mm) STANDARD LEAD Ã: 1 â 1,3mm 40.OL21 Z=3,1mmm 40.OL31 Z=3,9mm 40.OL24 Z=5mm REINFORCED LEAD Ã: 1 â 1,4mm 40.OL22 Z=3,1mm 40.OL32 Z=3,9mm 40.OL25 Z=5mm NOTE: With the TP6/PR-B it is possible to eliminate the stand-off form substituting the cutting/forming wheels with "only cutting wheels" TP6/PR-B/M A Motor-98 can be connected to the manual TP6/PR-B machine. TP6/PR-B Specs PDF

TP6/97 Cutting and bending machine for axial components with Quick-set-up This system automatically adjusts the bending wheels, reducing the set-up time and making it easier. This system is available with the some versions of the TP6 machine. 20.OL01/97 STANDARD LEAD Ã: 0,4 -1,2 (0.016" - 0.047") 20.OL04/97 REINFORCED LEAD Ã: 0,6 â 1,4 (0.024" - 0.055") 20.OL06/97 REDUCED LEAD Ã: 0,4 â 0,8 (0.016" - 0.031") IMPORTANT: the maximum pitch "P" that can be achieved with the /97 system is 40mm, and the maximum âBâ is 10mm TP6/97-M A Motor-98 can be connected to the manual TP6/97 machine. ALL TP6 Spec PDF TP6/97 Specs PDF

The following video shows the TP6/EC machine. The TP6/EC is the Economy version of the TP6 and works exactly the same way. The only difference is that the TP6 can be motorized and can use the loose feeder CS10 and the economy machine cannot.

Index | Accessories | Economy Machines | Counters | PCB Depanelers | Terminal Machine | Pin Machine | Hand Tools | BGA Reballer | Feeders & Special Machines | Flat Cable Separator | Parts Lists Axial Machines TP6 | TP6/D | TP6/97 | TP6/PR-B | TP6/PR-F | TP6/V | TP6/V-PR | TP6/S TAPED COMPONENTS LOOSE COMPONENTS FOR TAPED COMPONENTS, THE MACHINES CAN BE MANUAL OR MOTORIZED TO USE THE LOOSE COMPONENTS MACHINES NEED TO BE MOTORIZED TP6 Cut and bend machine for axial components. Several versions available designed for leads with lead diameters from .015 - .055" (0.4-1.4mm) ALL TP6 Spec PDF TP6 Spec PDF 20.OL01 STANDARD LEAD Ã: 0,4 -1,2 (0.016" - 0.047") 20.OL04 REINFORCED LEAD Ã: 0,6 â 1,4 (0.024" - 0.055") 20.OL06 REDUCED LEAD Ã: 0,4 â 0,8 (0.016" - 0.031") 20.OL07 / 9 / 10 REDUCED FIX PITCH LEAD Ã: 0,4 â 0,6 (0.016" - 0.024") 20.OL0130 STRAIGHT CUT TP6/M A Motor-98 can be connected to the manual TP6 machine. BODY GUIDES When it is necessary to bend very close to the body and the components are not taped with the component body properly centered, the body guides feed the tape by keeping the component body centered at all times. The body guides are used instead of the tape guides. More Body Guides info PDF We also offer Hand Tools for Cut, Form or Cut & Form. The following video shows the TP6/EC machine. The TP6/EC is the Economy version of the TP6 and works exactly the same way. The only difference is that the TP6 can be motorized and can use the loose feeder CS10 and the economy machine cannot.

“Manufacturing industries of every kind are rushing to utilise CF reinforced composite materials without a clear plan to process their products and structures at the end of their life cycle. CFR-TN is clearly the leading technology to provide each of those industries with a proven solution to avoid already bulging landfills around the world.” (READ FULL TESTIMONIAL)

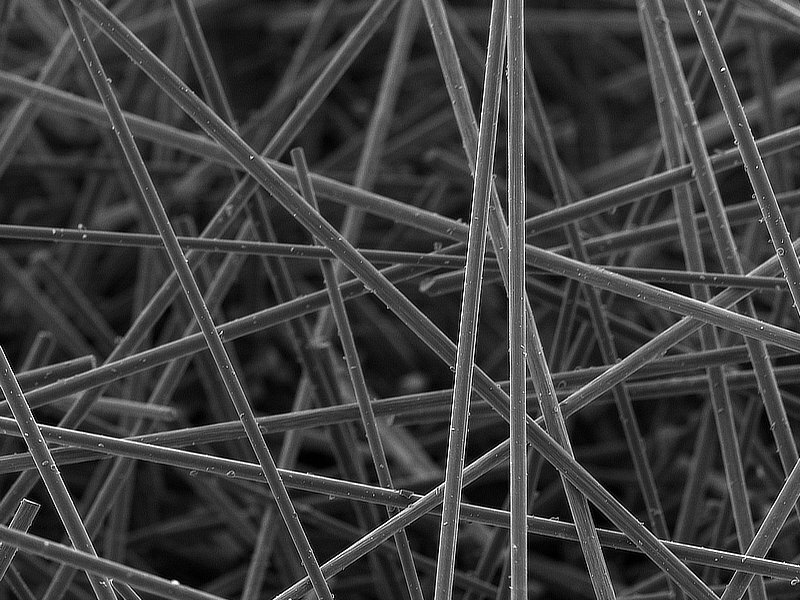

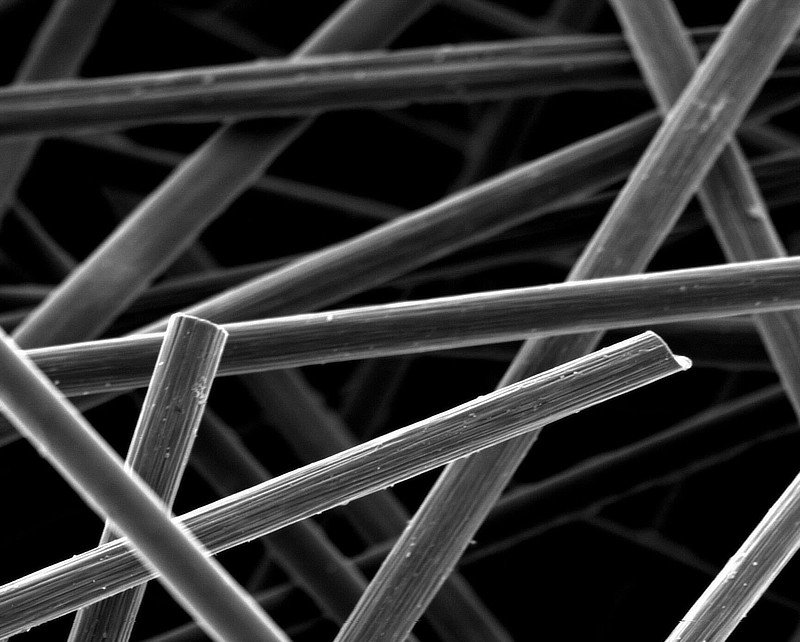

“As a wet laid nonwoven manufacturer, the quality of the fibers dictates the quality of our product. Especially when it comes to a recycled carbon fiber. It is vital to have a properly recycled fiber that does not carry matrix or charr residues. Carbon Fiber Recycling succeeded in providing us with high quality fibers that we were able to turn into high quality nonwoven fabrics. In addition, the Carbon Fiber Recycling team has been an amazing group to work with. They are very professional, always welcoming and carry the positive attitude towards innovation and new projects.”

CFR produces clean recycled carbon fiber at a fraction of the cost of virgin fiber. It can be used in many applications, creating the closed loop customers increasingly demand.

This system automatically adjusts the bending wheels, reducing the set-up time and making it easier. This system is available with the some versions of the TP6 machine. 20.OL01/97 STANDARD LEAD Ã: 0,4 -1,2 (0.016" - 0.047") 20.OL04/97 REINFORCED LEAD Ã: 0,6 â 1,4 (0.024" - 0.055") 20.OL06/97 REDUCED LEAD Ã: 0,4 â 0,8 (0.016" - 0.031") IMPORTANT: the maximum pitch "P" that can be achieved with the /97 system is 40mm, and the maximum âBâ is 10mm TP6/97-M A Motor-98 can be connected to the manual TP6/97 machine. ALL TP6 Spec PDF TP6/97 Specs PDF

Our mission is to recycle 100% of your excess and end of life carbon fiber. CFR transforms materials into clean short chopped fiber to be reused in the manufacturing process.

Axialcut in Film

“CFR has been an incredibly innovative and fast moving partner in the development of our award winning bicycle tire sealant. Tim and his team are wonderful communicators who were able to help us move from development to production in record time!”

TP6/A TP6 machine with Motor-98 and CS10 loose parts feeder. See other accessories available. Video of the CS10. Do not want to buy a motor and loose parts feeder but still have to prep loose parts? We have tape guides suitable for loose components that facilitate feeding low volumes of loose parts: More info PDF

TP6-D Axial Cut and Bend machine for Axial Components with Delrin Inner Discs. The TP6-D cuts & bends axial components as the regular TP6, with the difference that this machine has Delrin instead of metal inner discs so it will not mark the surface of the leads of the components when it bends them. This is important when working with very small and delicate components and for Military applications. 20.OL11 Standard machine 20.OL12 Reinforced machine Minimum cutting length "B" = 4.6mm and maximum lead diameter "d" = 0.8mm TP6/D-M A Motor-98 can be connected to the manual TP6/D machine. ALL TP6 Spec PDF TP6/D Spec PDF

Copyright ©2001-2024 OLAMEF USA, INC. Last Update: 04/30/2024 WEBMASTER Home About us Index of Products Contact us News Top Preforming Machines for: Axiales components Loose Radial components Taped Radial components Transistors IC machines & IC Formers Line of Economy Machines PCB Depanelers (Separators): FOR SCORED PCBs: - Maestro2, 3E, 4S, 5L - SEP1, SEP1M, SEP2, SEP2M FOR TABBED PCBs: - Hektor 2 & SEP3 Manual Depaneling Tools Feeders & Special Machines Accessories Component Counters Forming Hand Tools Pin Header Cutting Machine BGA Reballer Flat Cable Separator Fastor/Terminal Cutting Machine Spare Parts Lists Manuals Catalogs Forms Top

Axialcut Machining

Index | Accessories | Economy Machines | Counters | PCB Depanelers | Terminal Machine | Pin Machine | Hand Tools | BGA Reballer | Feeders & Special Machines | Flat Cable Separator | Parts Lists Axial Machines TP6 | TP6/D | TP6/97 | TP6/PR-B | TP6/PR-F | TP6/V | TP6/V-PR | TP6/S TAPED COMPONENTS LOOSE COMPONENTS FOR TAPED COMPONENTS, THE MACHINES CAN BE MANUAL OR MOTORIZED TO USE THE LOOSE COMPONENTS MACHINES NEED TO BE MOTORIZED TP6 Cut and bend machine for axial components. Several versions available designed for leads with lead diameters from .015 - .055" (0.4-1.4mm) ALL TP6 Spec PDF TP6 Spec PDF 20.OL01 STANDARD LEAD Ã: 0,4 -1,2 (0.016" - 0.047") 20.OL04 REINFORCED LEAD Ã: 0,6 â 1,4 (0.024" - 0.055") 20.OL06 REDUCED LEAD Ã: 0,4 â 0,8 (0.016" - 0.031") 20.OL07 / 9 / 10 REDUCED FIX PITCH LEAD Ã: 0,4 â 0,6 (0.016" - 0.024") 20.OL0130 STRAIGHT CUT TP6/M A Motor-98 can be connected to the manual TP6 machine. BODY GUIDES When it is necessary to bend very close to the body and the components are not taped with the component body properly centered, the body guides feed the tape by keeping the component body centered at all times. The body guides are used instead of the tape guides. More Body Guides info PDF We also offer Hand Tools for Cut, Form or Cut & Form. The following video shows the TP6/EC machine. The TP6/EC is the Economy version of the TP6 and works exactly the same way. The only difference is that the TP6 can be motorized and can use the loose feeder CS10 and the economy machine cannot.

CFR’s patented low emissions technology solution uses over 90% less energy than virgin carbon fiber and produces the cleanest recycled carbon fiber in the industry.

CFR recycles most carbon fiber materials including dry fiber, prepreg, and cured composites. There is no fee to recycle. You improve your carbon footprint, and enhance your brand.

Axialcut meaning

CFR produces clean recycled carbon fiber at a fraction of the cost of virgin fiber. It can be used in many applications, creating the closed loop customers increasingly demand.

Axialcut in anatomy

CFR recycles most carbon fiber materials including dry fiber, prepreg, and cured composites. There is no fee to recycle. You improve your carbon footprint, and enhance your brand.

Index | Accessories | Economy Machines | Counters | PCB Depanelers | Terminal Machine | Pin Machine | Hand Tools | BGA Reballer | Feeders & Special Machines | Flat Cable Separator | Parts Lists Axial Machines TP6 | TP6/D | TP6/97 | TP6/PR-B | TP6/PR-F | TP6/V | TP6/V-PR | TP6/S TAPED COMPONENTS LOOSE COMPONENTS FOR TAPED COMPONENTS, THE MACHINES CAN BE MANUAL OR MOTORIZED TO USE THE LOOSE COMPONENTS MACHINES NEED TO BE MOTORIZED TP6 Cut and bend machine for axial components. Several versions available designed for leads with lead diameters from .015 - .055" (0.4-1.4mm) ALL TP6 Spec PDF TP6 Spec PDF 20.OL01 STANDARD LEAD Ã: 0,4 -1,2 (0.016" - 0.047") 20.OL04 REINFORCED LEAD Ã: 0,6 â 1,4 (0.024" - 0.055") 20.OL06 REDUCED LEAD Ã: 0,4 â 0,8 (0.016" - 0.031") 20.OL07 / 9 / 10 REDUCED FIX PITCH LEAD Ã: 0,4 â 0,6 (0.016" - 0.024") 20.OL0130 STRAIGHT CUT TP6/M A Motor-98 can be connected to the manual TP6 machine.

Axialcut example

IMPORTANT: the maximum pitch "P" that can be achieved with the /97 system is 40mm, and the maximum âBâ is 10mm TP6/97-M A Motor-98 can be connected to the manual TP6/97 machine. ALL TP6 Spec PDF TP6/97 Specs PDF

Two main versions are available. The first one for components with lead diameters .019-.031" (0.5-0.8mm). The second one for thicker leads .031-.051" (0.8-1.3mm). Tooling for different pitches is available. TP6/V Specs PDF

Index | Accessories | Economy Machines | Counters | PCB Depanelers | Terminal Machine | Pin Machine | Hand Tools | BGA Reballer | Feeders & Special Machines | Flat Cable Separator | Parts Lists Axial Machines TP6 | TP6/D | TP6/97 | TP6/PR-B | TP6/PR-F | TP6/V | TP6/V-PR | TP6/S TAPED COMPONENTS LOOSE COMPONENTS FOR TAPED COMPONENTS, THE MACHINES CAN BE MANUAL OR MOTORIZED TO USE THE LOOSE COMPONENTS MACHINES NEED TO BE MOTORIZED TP6 Cut and bend machine for axial components. Several versions available designed for leads with lead diameters from .015 - .055" (0.4-1.4mm) ALL TP6 Spec PDF TP6 Spec PDF 20.OL01 STANDARD LEAD Ã: 0,4 -1,2 (0.016" - 0.047") 20.OL04 REINFORCED LEAD Ã: 0,6 â 1,4 (0.024" - 0.055") 20.OL06 REDUCED LEAD Ã: 0,4 â 0,8 (0.016" - 0.031") 20.OL07 / 9 / 10 REDUCED FIX PITCH LEAD Ã: 0,4 â 0,6 (0.016" - 0.024") 20.OL0130 STRAIGHT CUT TP6/M A Motor-98 can be connected to the manual TP6 machine. BODY GUIDES When it is necessary to bend very close to the body and the components are not taped with the component body properly centered, the body guides feed the tape by keeping the component body centered at all times. The body guides are used instead of the tape guides. More Body Guides info PDF We also offer Hand Tools for Cut, Form or Cut & Form. The following video shows the TP6/EC machine. The TP6/EC is the Economy version of the TP6 and works exactly the same way. The only difference is that the TP6 can be motorized and can use the loose feeder CS10 and the economy machine cannot.

We recycle dry fiber, pre-preg, and cured composites, as long as it contains at least 50% carbon fiber and no glass fiber.

0086-813-8127573

0086-813-8127573