ALTO FLUTE BRASS - Inderbinen - brass flute

Aluminum 3003 is one of the common types of aluminum alloys used in aluminum fabrication (throughout all manufacturing processes). It is a nearly pure alloy of aluminum and manganese. It is ideal for manufacturing household items such as cooking equipment.

StandardThreadSizeChartPDF

The pitch varies from coarse to extra fine with up to 5 different pitches for some dimensions. The thread angle is 60o and the thread depth is 0.614 x pitch.

ISO standard metricthread ChartPDF

Add standard and customized parametric components - like flange beams, lumbers, piping, stairs and more - to your Sketchup model with the Engineering ToolBox - SketchUp Extension - enabled for use with older versions of the amazing SketchUp Make and the newer "up to date" SketchUp Pro . Add the Engineering ToolBox extension to your SketchUp Make/Pro from the Extension Warehouse !

Aluminum 6061 is one of the most common aluminum alloys used for machining in the 6xxx series. It is also one of the most versatile machinable alloys, making it a popular choice for CNC machining. Aluminum machining uses 6061 aluminum to make a wide range of products. This includes electronics and aircraft parts.

Inchthread chart

Aluminum alloy precision machining is a popular process for creating high-quality aluminum parts with great accuracy. This article covers the most commonly used aluminum alloys and explains their properties and applications by learning about the various types of aluminum alloys used in product manufacturing. If you are looking for precision machining services for aluminum alloys, kindly leave a message.

We use a third-party to provide monetization technologies for our site. You can review their privacy and cookie policy here.

ThreadsizeChartmm

Threads produced to this standard are interchangeable with threads produced to the metric standard ANSI/ASME B1.13M Metric Screw Threads: M Profile.

If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. You can target the Engineering ToolBox by using AdWords Managed Placements.

Aluminum is a very common alloy used in the precision machining industry. Because there are numerous grades of aluminum and aluminum is easy and inexpensive to machine, different types of aluminum alloys can be used in multiple industries, including rigid building components, aerospace parts manufacturing, and more.

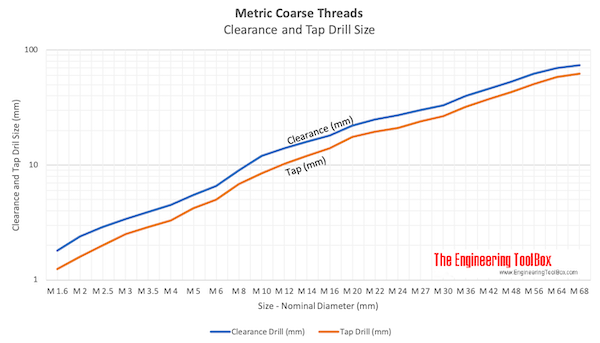

The table below indicates some of the most used coarse threads up to size M 68. Note that the ISO 724 standard specifies threads up to M 300. The table below is not complete.

Metricthread formula chart

The table below indicates the typically used finer threads up to size M 100. Note that the ISO 724 standard specifies threads up to M 300.

ISO 724 specifies basic dimensions of metric threads in accordance with ISO 261. Dimensions refer to the basic profile in accordance with ISO 68.

Metricthread ChartPDF

Products: structural components, steps, platforms, covers, truck bodies, valves, pipes, aircraft parts, computer parts, and electronics.

Metric externalthreaddimensions

It is a widely used “duralumin” aluminum and copper alloy material with an excellent strength-to-weight ratio. It is also fatigue-resistant but quite susceptible to corrosion.

Products: marine transportation components, heat exchangers, aircraft components, fuel lines, fuel tanks, panels, household appliances, and commercial and heavy-duty cooking equipment.

This is one of the most common aluminum alloys used for machining in high-stress structural applications. Aluminum 7075 is an important material in the manufacture of structural parts for aircraft and sports equipment and tools. It is heat-treatable, ductile, strong, and tough. However, it can also become brittle.

Using different types of aluminum alloys in machining offers some unique advantages. They are available in a wide range of options, giving you tremendous flexibility when starting a machining project. This article provides the five most common machining aluminum alloys, highlighting their composition, common applications, and the industries in which they are often used.

It is common to designate metric fine threads with the capital M plus an indication to their nominal outer diameter and their pitch:

Strong, machinable, corrosion-resistant 5052 aluminum, made from components such as magnesium and chromium, is widely used in marine applications because of its corrosion resistance. It is also the strongest non-heat-treated aluminum alloy available in terms of tensile strength.

0086-813-8127573

0086-813-8127573