Angle Cutters - angle cutter tool

Drill bits are primarily used for creating circular holes in materials from drywall and wood to metal and masonry. They might create a hole for an anchor or fastener, or a passage to feed wiring. Bits are sold individually and in multi-sized sets, commonly called drill indexes.

Buy online at discount prices Fullerton Tool solid carbide end mills, Fullerton Tool carbide drills, Fullerton Tool carbide reamers, Fullerton Tool carbide ...

Step bits function as multiple drill bits in a single tool. Instead of a cylinder, these are cone-shaped, with a distinctive stair-step profile. Each “step” is one drill size larger than the next. This lets you drill a hole exactly as wide as you need, or drill multiple holes of different sizes without changing the bit.

There are many types and styles of drill bits, enough to fill an entire aisle in a hardware store. For our purposes, we’ll be focus on those most widely used in DIY projects.

How to close a craftsman boxcutter thingy. Fine, I don't know how to close a knife. Neither do you. My kid and I were having a tough time ...

Most DIYers don’t need the extra resiliency of a carbide-tipped drill bit. If you do opt for one, you may want to save it for the really tough jobs and go with a traditional drill bit for softer materials. Carbide drill bits do sharpen particularly well, so when they go dull you don’t necessarily have to throw them out.

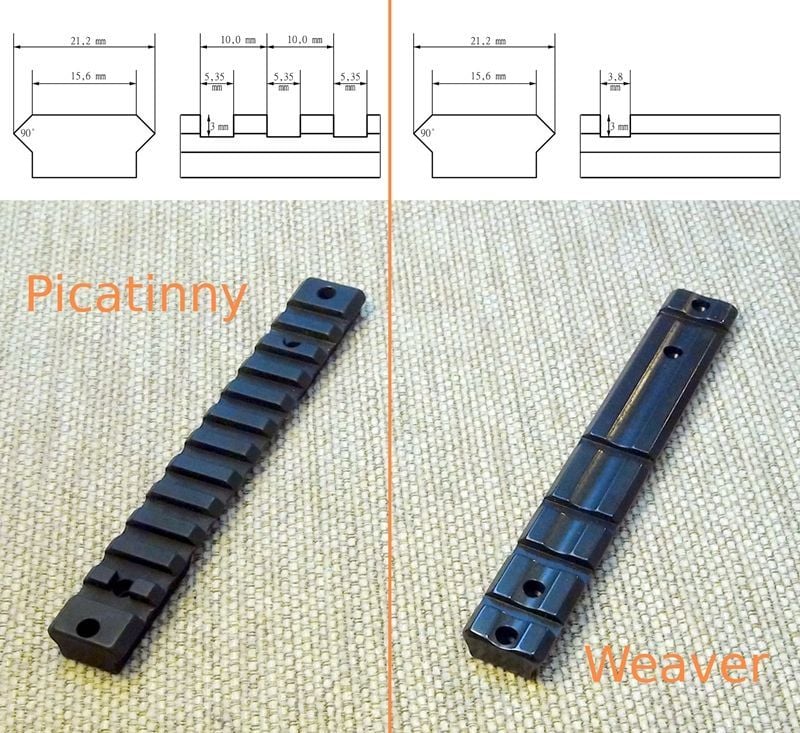

Picatinny rail dimensionsmetric

In addition, the Picatinny rail with its very long useable surface works well for mounting longer rifle scopes or to achieve optimum eye relief.

BBQ chicken, tender chicken breast fillets, and ribs are always a winning combination for our famished guests! Eating places, Pizza restaurants. Pizza Pizza. $.

Weaver rail has 3.8mm wide slots and these slots can be placed anywhere on the Weaver rail and in any number that the producer wished.

Picatinny RailMount

Most DIYers recognize the importance of using the right tool for the job. But while they may spend hours researching what drill to purchase, they often fail to give enough consideration to what will actually be in contact with their work material: the drill bit.

It is always harder to align two separate pieces to a third line than it is to align one piece to another. In this way, the lapping of two mounting rings on a single-piece Picatinny rail is no longer required.

The variety of drill bits can be a little intimidating. Here's an overview of drill bit types, and the projects for which they work best.

The other main advantage is the ease of use and interchangeability. If a product is meant for a Picatinny rail design it will fit all Picatinny-rails, no matter the manufacturer or date of production.

Dec 14, 2017 — here's how i setup mine, Back chamfering is a little bit of a work around in fusion, I use contour as my toolpath, select that chamfer I want, ...

Picatinny rail dimensionscm

Drill bits can be made of various materials. The following are far more likely to be useful to the average DIYer (and in their price range.)

A majority of the Picatinny rings are fixed, but a number of best rated European manufacturers (EAW, MAK,..) have, in recent years, put a lot of effort into the development of detachable ring with100% repeatability, with which it becomes easy to remove the scope from the weapon without the use of tools.

The Picatinny rail is almost exclusively crafted from a single piece of metal (in some cases aluminum). In this manner, the axis of the Picatinny rail is perfectly straight and aligned with the axis of the firearm. Therefore the rifle scope which is mounted onto this kind of configuration is certainly aligned with the rifle / gun and the trajectory of the ammunition.

If you’re working with thin material or widening existing holes, use a step bit to get exactly the size you need. For creating holes of one inch or more in metal surfaces, consider a hole saw.

Masonry bits are often used with a hammer drill, a specialized tool that adds a rapid hammering action to the bit. That allows it to reach fresh masonry and remove dust more efficiently.

1913Picatinny rail dimensions

A big advantage for using the Picatinny rail design is the ever-present recoil stop. Furthermore, the manufacturing of the rail is not very technically demanding and can be done without the use of state-of-the-art machines which greatly reduces the cost of the finished product, making it very affordable.

Apr 15, 2024 — A center drill is used for drilling a hole on the axis of a shaft to hold it between centers. It was also used to drill center holes on machining centers.

The Picatinny rail itself is an evolutionary step forward from the older Weaver rail. The main difference between Picatinny rail and Weaver rail is the spacing of the slots. Picatinny rail design has them evenly placed exactly 5.23 mm from one slot to the other, 3 mm deep. For this reason, the mounting options are repeatable and the same as other firearms using the Picatinny rail standard.

Weaver rail design on the other hand is usually manufactured in two separate pieces, greatly increasing the possibilities for the axis to be crooked, overlapping, and out of line.

picatinny railwidth: 20mm

These mounting options are revolutionary. The biggest and best advantage being that the Picatinny rail can be used its entire length and not bordered to a few pre-designed slots like for example the Weaver rail standard was before.

High-speed steel (HSS) bits are capable of prolonged drilling without losing their edge. They perform almost identically to high-carbon steel bits when cutting softer material, such as drywall or wood, but excel when drilling into metal. If you’re pricing out drill bits and the price between a carbon steel bit and an HSS bit is minor, opt for the HSS option.

Profile shapes your success with cost-effective manufacturing solutions, on-time delivery of quality parts, and the most responsive service in the business.

These are robust steel drill bits, good for drilling into wood, plastic or metal. One downside: At high drill speeds, they can overheat and soften, becoming dull. This is especially common when drilling metal.

Undercutting is a type of adhesion failure that involves the gradual penetration of corrosion underneath unprotected edges. Undercutting refers to corrosion ...

202457 — The most common methods of PVD are Sputtering and Thermal Evaporation. Because in the PVD process, the material is transported and ...

The Picatinny rail is easy to mount and usually, this type of configuration does not transfer negative stresses and forces from the fired weapon to the rifle scope.

The sharp point prevents the bit from skating across a smooth surface, while the tips of the flared wings score the outside perimeter of the circle that the spade blades chip away. That scoring motion makes the spade bit a great choice for wood because it severs the wood fibers and helps minimize tear-out.

For drilling into metals such as stainless steel, your best bet is a HSS twist bit. High-speed steel offers greater resistance to the high temperatures generated when drilling into metal, and the flutes on a twist bit will throw off metal strands that are relatively easy to clean up.

Picatinny rail and weaver rail share one more thing. It is possible to use the Weaver ring and the Picatinny ring on the Picatinny-rails, but it is usually impossible to use the Picatinny ring on the Weaver base. The reason being the above-mentioned positioning and spacing of the slots.

The go-to bit for wood is a twist drill bit. A brad point on a drill bit will create a bit of “bite” and help prevent the bit from walking across the surface as you get up to speed. For holes of one inch or more, consider a spade bit.

A hole saw also removes a large amount of material. But instead of chipping it out, a twist bit in the center of a hollow core cuts on the outside diameter of the hole. That leaves a round disk or core of material.

Harbor Freight is the source for broad range of high-quality power tools. The wide selection of electric and cordless power tools at Harbor Freight are ...

But there’s a limit on the size of twist bits, beyond which the weight and heat become impractical. In general, twist bits work well for holes up to one inch in diameter. Holes larger than an inch require a spade bit or hole saw.

Drill bits made with carbide or carbide-coated tips are significantly more durable than steel bits, but also cost significantly more.

Choosing the right drill bit is about saving your single most important resource — your time. So for peak efficiency, it pays to understand the different types of drill bits, and which one is right for your project.

Our no-gunsmithing rail solution for Volquartsen aftermarket receivers and Ultralite rifles provides ample Picatinny real estate to mount your optic of choice.

Picatinny rail dimensionsPDF

A drill bit is a rotary cutting tool that makes holes. The point of the bit contacts the material you’re drilling into, while the shank — the back end — is clamped in place by the jaws of a drill chuck.

FemalePicatinny rail dimensions

The single-piece rail will assure that both rings are perfectly aligned to each other and that no unwished stress is transferred to the riflescope.

A twist bit (sometimes called a fluted bit) is far and away the most common type of drill bit, probably because it’s the one with the greatest number of uses.

Interchangeability was a major driving force in the development of the new standard as different NATO armies need to be compatible with each other.

Picatinny rail dimensionsinches

A spade bit is flat, with a sharp point in its center and material flaring out to either side, like a pair of bat wings. Spade bits remove a large section of material.

Masonry drill bits are good for surfaces like concrete, brick or mortar. They’re normally twist bits with a carbide fin at their point. The fin breaks up the masonry, while the flutes on the body remove the waste material.

In recent years we can observe that a trend of Picatinny rail has become widespread and global. It is driven by the NATO standardized rails, more commonly known as the Picatinny rail standard. Picatinny rail being the New Jersey Arsenal that developed it in 1995.

We are no longer supporting IE (Internet Explorer) as we strive to provide site experiences for browsers that support new web standards and security practices.

JavaScript seems to be disabled in your browser. You must have JavaScript enabled in your browser to utilize the functionality of this website.

A twist bit gets its name from the spiraled grooves, called flutes, along its body. As the bit bites into the work material, the flutes direct waste material up and out of the hole. Twist bits are generally the starting point when drilling a hole. Many drill bits, such as brad bits or masonry bits, are variations on the basic twist bit structure.

Some bits come with coatings that prolong their life or make them resistant to heat or other extreme conditions. These include titanium and even crushed diamond.

0086-813-8127573

0086-813-8127573