Any tips on machining Titanium grade 5? : r/Machinists - milling titanium

Cathodic arc evaporation generates many ions that cause enough energy to produce TiN without substrate heaters. You can run the process at low enough temperatures to coat substrates with melting temperatures as low as plastic. Vapor Technologies customers can deposit cathodic arc TiN coatings in our VTi™-series machines. Below is a cross-sectional SEM micrograph of a TiN film deposited in our VT-1500i™ system.

Titanium Nitridecoatingthickness

Overall, using aluminium alloys for CNC machined parts provides an excellent combination of strength, durability, and versatility, making it a popular choice in many industries.

Aluminium Alloy 6063 has Magnesium and silicon as the main alloying elements and is typically used for architectural applications. Temper grade 6063-T6 is the most common and has good machinability.

Aluminium alloys, with their diverse mechanical properties, are not only an excellent choice for CNC machining but also a key consideration when designing for CNC machining. Their machinability and versatility make them ideal for numerous applications, from aerospace components to consumer products, where material selection is critical to achieving optimal performance and manufacturability.

Ti coatingpvdcoating

Aug 23, 2023 — Many boring issues can be solved by troubleshooting tooling implementation, including lengthy cycle times, short tool life, and poor part quality.

TiN has excellent mechanical, corrosive, and thermal properties to fit a range of applications. Manufacturers use TiN coatings in several industries, including biomedical, automotive, tools and tooling, and outdoor sports. The TiN cubic structure is very compatible with most metallic substrates, ensuring good coating adhesion on a wide variety of substrates.

The available color range deposited by the cathodic arc is broader than that from magnetron sputtering systems. Magnetron sputtering TiN is typically less yellow and redder than TiN deposited by cathodic arc evaporation. The color changes are caused by differences in ion energy, as discussed below.

Aluminium alloy 3003 is a non-heat treatable alloy primarily composed of manganese as its primary alloying element. It is generally used for sheet metal products, but thicker plates can be machined.

Generally known as commercial aerospace alloy, 7075 uses Zinc as its primary alloying element. Aluminium alloy 7050 is used in aerospace due to its high fatigue strength, high strength and high resistance to stress corrosion cracking.

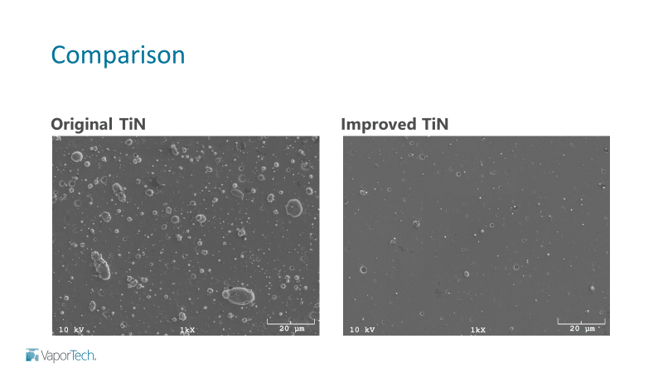

One intrinsic disadvantage of cathodic arc processes is the formation of macroparticles. These particles can produce hazier films with higher coefficients of friction. However, at VaporTech, we developed a process that deposits TiN films (and others) with significantly fewer macroparticles. The results show an increase in gloss of more than 20%. This process improves the look of the coating and improves its wear and coefficient of friction.

Introducing the Rotary Tool 1/8 in. Carbide Ball End Engraving Burr. This burr is ideal for carving, engraving, grinding, smoothing and edging rough areas ...

Titanium Nitridecoatingnear me

In addition to these benefits, aluminium alloys offer good electrical and thermal conductivity while being non-toxic and non-magnetic.

Aluminium alloy 2014 is known for its excellent machinability and has copper as its principal alloying element. It is the second most popular alloy after the 2024 in 2000 series. The 2014 alloy can be heat treated to improve mechanical properties and hardened to reach strengths similar to steel.

Alloy 6063 is used in architectural and structural applications such as window and door frames, handrails, furniture frames and structural components.

Surface SEM images of TiN films deposited in the VT-1000i™ system with the original process (left) and the improved (right).

Aluminium alloy 5083 is a non-heat treatable alloy with Magnesium as its primary alloying element. Aluminium alloy 5083 is known for its exceptional corrosion resistance, high strength and good weldability. Due to its high strength, it is moderately challenging to machine complex intricate designs.

Due to its high strength and high corrosion resistance in marine environments, engineers use Alloy 5083 in marine and naval applications such as Ship hulls and bulkheads, Offshore platforms, boats, yachts and submarine parts.

Schneider Electric Australia. 16030 - modular analog ammeter without scale iAMP - 0..2000 A.

The details of the most common aluminium alloys for machining and why they are among the best materials for different applications should be precise. Now, the best way to select the best type of aluminium alloy for a specific

Due to the above properties, engineers use aluminium alloy 6061 for aerospace components, automotive parts, bicycle frames and marine components.

Aluminium alloy 5052 has Magnesium as its primary alloying element and is a non-heat treatable alloy. These alloys are known for their excellent corrosion, good formability and moderate strength. Alloy 5052

Alloy 5052 is used in applications exposed to moisture and marine applications due to its exceptional resistance to corrosion in marine and saltwater environments.

Titanium nitridecoatingprocess

However, there are many different aluminium alloy types in the market. Therefore, selecting the adequate type of aluminium alloy for a specific application takes time and effort.

Product designers use Aluminium alloy 2011 for complex, intricate parts manufactured by automated manufacturing to produce appliance parts, automotive trims, fasteners, and fittings

Depositing TiN using PVD techniques typically involves a solid target made from very pure titanium, argon gas, and nitrogen as the reactive gas. The titanium (Ti) atoms/ions from the target react with the nitrogen (N) atoms from the reactive gas to create TiN. TiN formation requires relatively high activation energy generated by either heat or ion energy. Suppose the process does not contain enough energy during coating deposition. In that case, the resulting phase will only consist of Ti, which is much softer than TiN and exhibits a metallic gray appearance rather than gold.

3IL10ACME - Left Hand Internal American ACME Laydown Threading Insert 3/8" Inscribe Circle Size 10 Pitch **Only sold in quantities of 10.

Aluminium Alloy 2011 has copper as its primary alloying element and is known for its excellent machinability, often called Free Machining Alloy (FMA). The presence of Lead in the alloy improves its machinability, allowing product designers to create high-precision intricate parts.

Indexable Drilling · Drill Cartridges · Sandvik Coromant. * Image may not reflect actual product. Sandvik Coromant 5733203 T-Max® U Assembly Item, R/L430.26 ...

There are seven different aluminium alloys used in the industry. Each aluminium alloy series starts with a number representing the primary alloying element added to the pure aluminium. The following are the main aluminium alloy series used in CNC machining.

2017213 — 1. You Don't Need Extensive Experience or Skills With conventional machines, you do need a long period of experience to get the most out of them.

Snap-on has a long, proven track record of designing custom tool solutions for critical industries. We take a total team approach, with specialists who work ...

TiNcoatingspray

2024 alloy produces aircraft structures, fuselage, and wing elements. Engineers also use it in high-stress applications such as automotive, machinery and sports equipment.

Due to its excellent mechanical properties, automotive and aerospace industries frequently use aluminium alloy 2024. Compared to alloys 6061 and 7075, 2024 has lower corrosion resistance.

Product designers often use Aluminium alloy 2017 in high-strength structural parts, aircraft components, military equipment and rivets.

Aluminium alloy 6082 has the highest strength of all the 6000 series alloys. In Plate form, 6082 alloy is the most common type used for machining due to its ease of machining. It is comparably stronger than 6061. Increased amounts of manganese help control the grain structure, resulting in a stronger alloy.

Jul 23, 2018 — Thread Pitch and Threads Per Inch are used to measure the threading of a bolt or nut to ensure that they will couple together properly. If the ...

Aluminium alloys for CNC machining offers a range of advantages due to the material’s excellent mechanical properties and versatility. Hence, Aluminium alloys are one of the most popular materials for CNC machining for milling and turning.

Nevertheless, it is possible to select wisely by knowing the properties of aluminium in detail, its benefits for CNC machined parts, and the differences between the most popular types of aluminium alloys for CNC machining.

Solid Carbide Tapered Ball Nose · HSS 1-2 Flute Upcut and Downcut · 40-000 · 40 ... Door Lite Router Bits (Dor-Bits) · 15-40 · 15-50 · 15-75 · 33-00 · 33-110 · 34 ...

Titanium nitridecoatingat home

Due to its excellent formability and corrosion resistance, product designers use 3003 alloys in Radiators, HVAC systems, heat exchangers and chemical equipment.

Several PVD methods are used for TiN synthesis. Today, the most common methods are magnetron sputtering or cathodic arc evaporation. Each method has benefits and challenges, and each VaporTech® deposition system can use either technique or both.

Due to 7075 alloy’s excellent mechanical properties, engineers use the alloy for aerospace components, fuselage frames, aircraft structures, high-stress structural applications, military equipment and defence applications, bicycle frames and high-performance machinery.

Headquartered just outside Boulder, Colorado, VaporTech produces cathodic arc, magnetron sputtering, and combination (hybrid) systems in a range of sizes. The company helps customers optimize surface finishes, including TiN coating, for their specific applications. For more information, contact us today at vtsales@vaportech.com

Aluminium alloy 6061 is widely used due to its high strength, excellent formability and corrosion resistance. Alloy 6061 has Magnesium and silicon as the main alloying elements. Due to their comparably lower cost and excellent machinability, they are one of the most common aluminium alloys used for machining.

Aluminium alloy 2017 is a high-strength, heat-treatable alloy with copper as its primary alloying element. It has better ductility and formability properties compared to 2014. Aluminium alloy 2017 has excellent machinability in the T4 temper.

Ti coatingreviews

TiN films deposited via magnetron sputtering are very smooth and relatively defect-free. Still, the process typically used produces mainly low energic atoms, not highly energic ions, meaning the process lacks the energy needed to make TiN. Therefore, scientists often use substrate heaters’ additional heat to generate the required energy for TiN formation. Magnetron sputtering systems often create temperatures exceeding 400 C°, which limit the types of substrates coated. However, to overcome the energy deficiency of magnetron sputtering, enhance it with a supplemental energy source. At VaporTech, the RAAMS® (Remote Assisted Anode Magnetron Sputtering) process in our Cadence® system generates TiN films with significantly fewer defects without needing an additional heat source. These films are akin to those produced by cathodic arc evaporation but without the haze and other issues created by macroparticles.

Titanium nitridecoatingmachine

Due to its high strength-to-weight ratio and good machinability, engineering designers often use aluminium alloy 2014 in aerospace applications such as aircraft components and structural elements.

Apr 28, 2021 — Seems to me that the cutting data you quote are for industrial size milling machines, not a small SX1. My milling machine will not do 5000RPM, ...

Titanium Nitride (TiN) coating is one of the most well-known physical vapor deposition (PVD) choices and has been a mainstay of product finishing for decades. Customers like TiN because of its good mechanical properties and lustrous gold color. The combination of a non-metallic element (Nitrogen) with a transition metal element (Titanium) forms a refractory (resistant to alteration) material. The material exhibits many attributes associated with refractory nitride materials. These attributes include:

Finding the perfect balance might be complicated. Yet, by combining the requirements mentioned above, it will be easier to identify the aluminium alloy types for machining that will be suitable for a specific project. The last step would be ensuring the available budget covers the material needed.

Application is to make an informed choice. Therefore, it is crucial to understand the application requirements. By following five steps, we can obtain the necessary information to choose. These are the steps:

As mentioned before, several aluminium alloys are available in the market, and it is essential to understand their differences to choose the most adequate one for your specific application.

Aluminium alloy 7075 is a high-strength alloy known for its exceptional strength-to-weight ratio and excellent mechanical properties. 7075 uses Zinc as its primary alloying element.

0086-813-8127573

0086-813-8127573