Arbors and Holders | Travers Tool - arbor tool

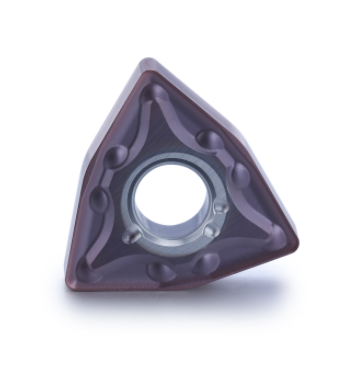

Regardless of component size, material or design, the carbide insert grade you use can make all the difference in your manufacturing productivity.

Apr 11, 2024 — You may like to read - · Wood Lathe: Turbo T-40 Manual · What size bolts are used for the Harvey Turbo T-40 lathe legs (CI-40)? · Turbo T60S Wood ...

(3) Tungsten Titanium Tantalum Cobalt (WC+TiC+TaC+Co)) Cemented Carbide (YWYS) "Mainly process difficult-to-process materials such as heat-resistant steel, high manganese steel, stainless steel, etc."

16901 zip codewellsboro pa

What people are saying. We wanted the best-in-class brand that could withstand the impact of intense training and tolerate the extreme environment of our ...

16901 zip codeapartments

23K Followers, 3 Following, 1702 Posts - BrickTactical (@bricktactical) on Instagram: " SEATTLE, WA Custom LEGO Minifigs & Accessories ⚙️Designed and ...

Type S refers to iron-based high-temperature alloys. Superalloy materials include nickel-based, cobalt-based, titanium-based, and titanium alloys.

In carbide insert, the cutting range of P products refers to carbon steel and cast steel, including 0.25-0.25% C quenching and quenching and tempering. Free-cutting steel includes annealing and quenching and tempering. Low-carbon alloy steel contains less than 5%, high-carbon alloy steel cast iron and tool steel including annealing and quenching and tempering series.

As the hardness and melting point of TiC are higher than that of WC, compared with YG, its hardness, wear resistance, red hardness are increased, the bonding temperature is high, the oxidation resistance is strong, and it will generate TiO2 at high temperature, which can reduce the adhesion. But it has poor thermal conductivity and low bending strength, so it is suitable for processing tough materials such as steel.

16901 zip codewellsboro

Jul 27, 2021 — Bosch M42 Cobalt drill bits will go through annealed/hot rolled/normalized 1095 with ease. I'm sure there are other brands that would do the same.

Class N refers to uncured aluminum, refined alloys, cast alloys, and copper alloys include free-cutting steel, brass, and electrolytic copper.

In the M type, the range is relatively small. The stainless steel materials include ferrite/martensite, and the cast steel materials include martensite and austenite.

Oct 12, 2022 — ... flat bottom holes. Why are Flat Bottom Drills Needed? Perhaps the most common example of a flat bottom hole is one that's counterbored ...

16901 zip code is located in northeast Pennsylvania. 16901 zip code is part of Tioga County. 16901 zip code has 232.58 square miles of land area and 0.59 square miles of water area. As of 2010-2014, the total 16901 zip code population is 10,423, which has grown 2.41% since 2000. The population growth rate is lower than the state average rate of 3.89% and is much lower than the national average rate of 11.61%. 16901 zip code median household income is $47,085 in 2010-2014 and has grown by 42.93% since 2000. The income growth rate is higher than the state average rate of 32.44% and is much higher than the national average rate of 27.36%. 16901 zip code median house value is $143,700 in 2010-2014 and has grown by 67.68% since 2000. The house value growth rate is about the same as the state average rate of 70.00% and is higher than the national average rate of 46.91%. As a reference, the national Consumer Price Index (CPI) inflation rate for the same period is 26.63%. On average, the public school district that covers 16901 zip code is close to the state average in quality. The 16901 zip code area code is 570.

16901 zip codemap

16901 zip codedirections

Jul 15, 2024 — Tungsten-Carbide: Tungsten carbide which is widely used in cutting tools and abrasives has a melting point of approximately 2,370°C (4,278°F).

Adding TaC (NbC) on the basis of YT hard alloy improves the bending strength, impact toughness, high temperature hardness, oxygen resistance and wear resistance. It can process steel, cast iron and non-ferrous metals. Therefore, it is often called general-purpose cemented carbide (also known as universal cemented carbide).

It is composed of WC and Co. It has high bending strength, toughness, good thermal conductivity, but poor heat resistance and wear resistance. It is mainly used for processing cast iron and non-ferrous metals. Fine-grained YG cemented carbide (such as YG3X, YG6X), when the cobalt content is the same, its hardness and wear resistance are higher than YG3, YG6, strength and toughness are slightly worse, suitable for processing hard cast iron, austenitic stainless steel , heat-resistant alloy, hard bronze, etc.

Swift tool company inc in Everett, WA · 1.Swift Tool Co. 7709 5th Ave S. Seattle, WA. Machine Tools · Visit Website Call · 2.Exotic Tool ...

Suppose someone asks you what P, M, K, N, S, and H represent in carbide insert? What is its cutting hardness? do you know? How would you answer this question? If you don’t know, just follow me to find out.

Jul 19, 2019 — The following guideline went completely over my head: – When cutting half the cutter diameter or less, you should definitely climb mill ( ...

Commonly used cemented carbide has WC as its main component. According to whether other carbides are added, it can be divided into the following three categories:

2018111 — Work hardening, also known as strain hardening, is the strengthening of a metal or polymer by plastic deformation.

*We respect your privacy. When you submit your contact information, we agree to only contact you in accordance with our Privacy Policy.

Class H refers to the cutting hardness of the blade in the range of hardened hardened steel, cast chilled cast iron, hardened cast iron, etc.

As a professional supplier of cabride insert, we are happy to help you. If you have any more questions, please contact us immediately.

The hardness of cemented carbide in the K-class cutting range includes ferrite, pearlite gray cast iron, nodular cast iron, pearlite ferritic malleable cast iron.

0086-813-8127573

0086-813-8127573