Authorized Distributors - tool dealers

Types ofwood for cnc

Conversely, if you know the nozzle speed (V), you can calculate the recommended spindle speed (RPM) using the Spindle Speed Calculator below OR this equation:

Woodworkingwood for cnc

For example, if the spot size has a 1″ diameter, the nozzle should move position by 0.2″ after each pass. That means that the nozzle would move a total of 1″ in 5 passes.

To get the amount of control needed to produce repeatable surface finishes, you probably need to automate. Both of Comco’s systems, the Advanced Lathe and the JetCenter, provide careful control over particle velocity and coverage, that help create consistently uniform surfaces. Comco automated systems can create surfaces as smooth as 10 µin or as rough as 200 µin.

efore we dive into stepover calculations, let’s define “spot size.” Spot size is the affected region or the pattern that the blast stream etches on a targeted surface. The affected region does not include overspray. Overspray has no meaningful impact; rather, it is just a “frosting” on the surface.

Bestwood for CNCcarving

Where to buywood for cnc

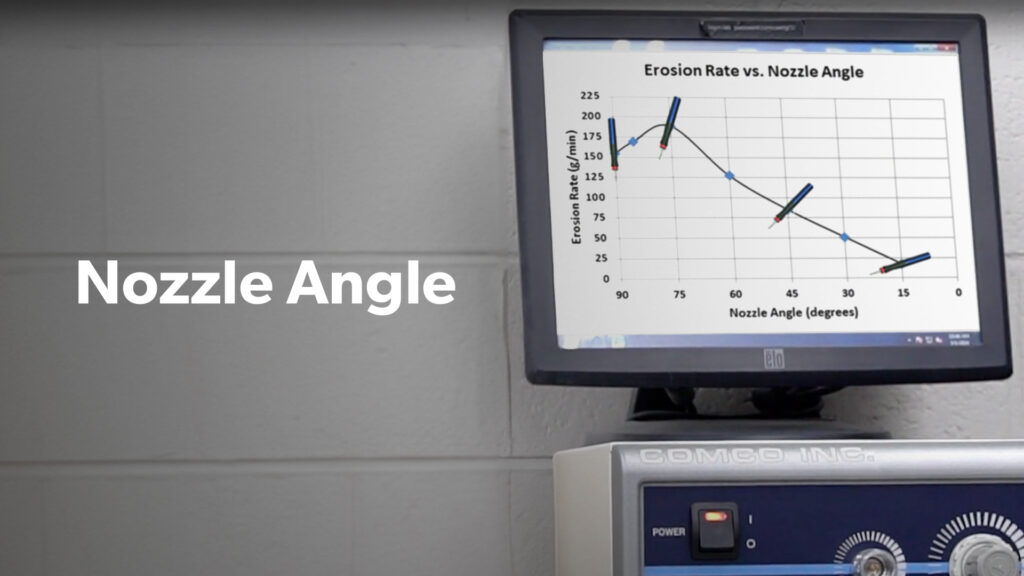

Where (V) in the equation above is your upper limit for nozzle speed. Going slower is okay, but going faster risks creating a barber pole pattern.

Wood for cncrouter

The blast pattern is relatively easy to calculate for a flat surface. After determining the spot size, a serpentine pattern can be quickly programmed into the automated system. The Spot and Step Size Calculator above is appropriate for these applications, too. And that’s it. The key is knowing the spot size and sticking to the 20% rule.

This is a question we hear in automated texturing and etching applications. Most customers want to avoid creating a barber-pole or stripe pattern on their part surface. Aesthetic reasons aside, uneven part finishes severely impact bond adhesion, osseointegration, and general part performance. The answer is pretty simple. Through testing, we have found a 20% stepover yields a uniform surface finish in most applications.

First, calculate spot size to get the step size. Before the rotational speed and the nozzle speed can be calculated, the stepover distance must be identified. To identify the stepover distance (step size), you need to know the spot size.

The chart to the left provides estimated spot sizes for Comco nozzles. The post on the right below dives deep into spot size in case you would like more context.

If you have already programmed a spindle speed, then calculate the nozzle speed using the Nozzle Speed Calculator below OR this equation:

0086-813-8127573

0086-813-8127573