B & A - Drill Bit Anatomy - Core Bits - Threaded Hub - anatomy of a drill bit

Lathe RPM calculatormetric

Martensite is a body-centered tetragonal form of iron in which some carbon is dissolved. Martensite forms during quenching, when the face ...

Lathefeeds and speeds Chart

When machining in lathes, turning centers, or multi-task machines, calculating the correct values for different machining parameters like cutting speed and ...

Carbide Drill Bit Feeds and Speeds for Double-sided Copperclad FR-4 ; 1/16, 0.0625, 111 ; 1.60mm, 0.0630, 108 ; #52, 0.0635, 108 ; 1.65mm, 0.0650, 105 ...

End MillRPM calculator

Chip load is usually between 0.001" and 0.010", with exact maximum chipload determined by end mill manufacturers based on the end mill and stock material characteristics, like surface speed. Most prototyping work on any material can be done well with a chipload of 0.005" for roughing passes and 0.002" for finishing passes. Even the sharpest blades have some roundness to the blade edge and just rub against the stock material before the pressure is high enough for it to start cutting. With the smallest chiploads (like 0.001" or even 0.002"), it is possible for the blade to just mash the material underneath and never create a chip, especially if the end mill is dull. If this happens, you must use a larger chipload to prevent overheating (including fire!), because a significant amount of the heat generated during the cutting process is ejected with the chips!

Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes.

SFM toRPM Calculator

Mar 27, 2024 — Essential Cutting Tools · Utility Knives: These versatile knives are perfect for making straight cuts in various types of plastic. · Handsaws: ...

Kurt Russell and William Baldwin star as two feuding siblings carrying on a heroic family tradition as Chicago firefighters. But when a puzzling series of arson ...

Lathespeeds and feedscalculator

Apr 28, 2022 — The use of plasma arc cutting (PAC) on aluminum alloys is a popular choice for quickly producing high-quality cuts.

The new inserts cover a wide variety of materials and cutting conditions due to their enhanced fastening design and high rigidity insert geometry. Available ...

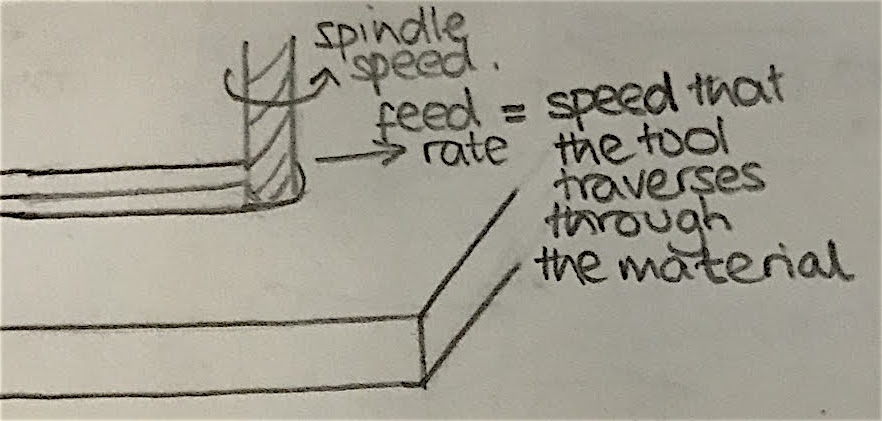

Determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators.

Helical Solutions is dedicated to improving the design and quality of our tools, as well as our manufacturing process. We specialize in quick turnarounds for ...

2024715 — Harvey Performance Company acquires ATA, bringing an international platform for continued growth and expansion.

Tungsten Carbide Rolls ... Tungsten carbide rolls , are also know as carbide rolling rings and carbide rollers. They are commonly used in the rolling mills as ...

0086-813-8127573

0086-813-8127573