Bar Chamfering Machines - chamfering device

Using the latest Mastercam cad/cam software and our experience in tool and mold technology, we take tooling to a new level More Information...

Specialty tool & machine incomaha ne

Given that fact that no two projects are alike, we have acquired the ability and expertise to machine just about anything you need. With our investment in state of the art CNC machining centers and corresponding tooling, we can easily machine most materials.

Specialty tool & machine incjobs

Serving the needs of the food and consumer packaging industry as well as tooling for automotive appliques, with the accuracy you desire More Information...

Our engineering department is ready to get started on your project. Using the latest SolidWorks and Mastercam cad/cam software, we can create the products you need with the accuracy you desire. Our ability to read multiple file types means that data communication is seamless and dependable

The Widin Carbide Rib Processing End Mills - 2 Flute Ball Nose (WB712P) are high-performance cutting tools specifically designed for rib processing applications. With their two flutes and ball nose configuration, these end mills excel at creating precise and smooth contours in narrow ribs. The carbide construction ensures exceptional durability and wear resistance, enabling extended tool life and reducing the need for frequent replacements. The ball nose design allows for efficient and accurate machining of curved surfaces and intricate details, resulting in superior surface finish and dimensional accuracy. Whether you're working with aluminium, steel, or other materials, the WB712P delivers consistent and reliable performance. The sharp cutting edges and optimized flute geometry ensure efficient chip evacuation, reducing the risk of chip clogging and improving overall machining efficiency.

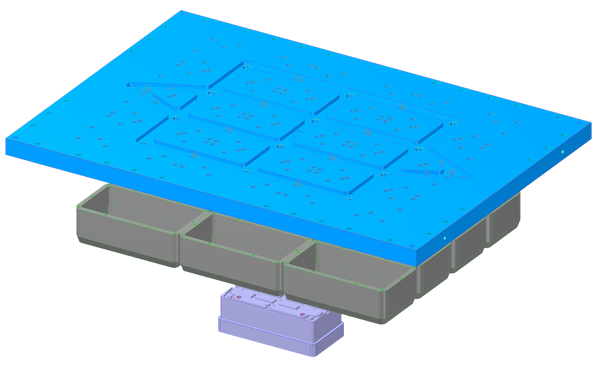

Specialty Tool & Mold Inc. is a manufacturer of custom thermoform molds and trim tooling. We have been located in Grand Rapids, Michigan since 1967. We serve the needs of the food and consumer packaging industries as well as tooling for automotive appliques. We cover both the contact heat cut-in-place and radiant heat plug assist in-line process. In addition to single edge dies and match metal dies for the thermoform process, we also specialize in compound dies for the gasket cutting industry.

Specialty Toolmanufacturing company

We use high quality CNC' s Industrial drills, presses and the some of the most experienced machinists to produce only the best products More Information...

Serving the needs of the food and consumer packaging industry as well as tooling for automotive appliques, with the accuracy you desire More Information...

Meeting and exceeding our customers’ needs is our number one priority. Regardless, if your project is complicated or simple, it is of high value to Specialty Tool & Mold Inc. and we can ensure total satisfaction with your project.

Located just 10 minutes south of Grand Rapids, MI our facility is right in the heart of the Midwest. With Gerald R. Ford International airport located less than 7 miles away and various trucking and logistics options are available. We are ready to ship land, air or sea.

Specialty tool & machine incowner

The Widin Carbide Rib Processing End Mills - 2 Flute Ball Nose (WB712P) are high-performance cutting tools specifically designed for rib processing applications. With their two flutes and ball nose configuration, these end mills excel at creating precise and smooth contours in narrow ribs. The carbide construction ensures exceptional durability and wear resistance, enabling extended tool life and reducing the need for frequent replacements. The ball nose design allows for efficient and accurate machining of curved surfaces and intricate details, resulting in superior surface finish and dimensional accuracy. Whether you're working with aluminium, steel, or other materials, the WB712P delivers consistent and reliable performance. The sharp cutting edges and optimized flute geometry ensure efficient chip evacuation, reducing the risk of chip clogging and improving overall machining efficiency.

Do you have a project that we can assist you with? You can contact us either by filling out this contact form or by giving us a call at (616) 531-3870. We can’t wait to hear from you!

Specialty tool & machine incomaha

Specialty Tool & Mold Inc. is set up for and has processes in place to meet the quick demand of our customers. This allows us, to provide the highest quality tooling in the shortest amount of time possible.

The employees at Specialty Tool & Mold Inc. are experts in their field. They are an integral part of a team approach when working on your project. With our diverse experience in manufacturing, we have the ability to think “outside the box” when providing tooling solutions. This is key to producing exceptionally designed, engineered and manufactured tooling.

We continues to enhance our visibility and reputation, including exhibitions all over the world and we also actively taking corporate social responsibility.

We live in a time when every minute matters and quality can’t be compromised. Because of this, we have processes set up and employees with the expertise to make the delivery time you need and can depend on. Speed, accuracy and quality craftsmanship are things we pride ourselves in when working on your project.

0086-813-8127573

0086-813-8127573