Bespoke Shadow Boards, Management Boards & Accessories - bespoke tools

The main difference between both operations is that Pocket will keep a constant engagement of your mill in the stock, while Adaptive Clearing will take bites, alternating cutting and cooling.

Please note that there are many valid ways of milling, and that Fusion360 offers other milling operations than the ones we’ll present in this article. We decided to focus on the ones our Mekanika community uses the most on their own CNC milling machines. After reading this article, we strongly recommend that you try different options and see what works best for you.

Specifically, this involves removing sharp edges and burrs from the workpiece to form a flat, chamfered slope. This slope is generally machined at a 45 degree angle, but the angle may vary depending on the use and purpose.

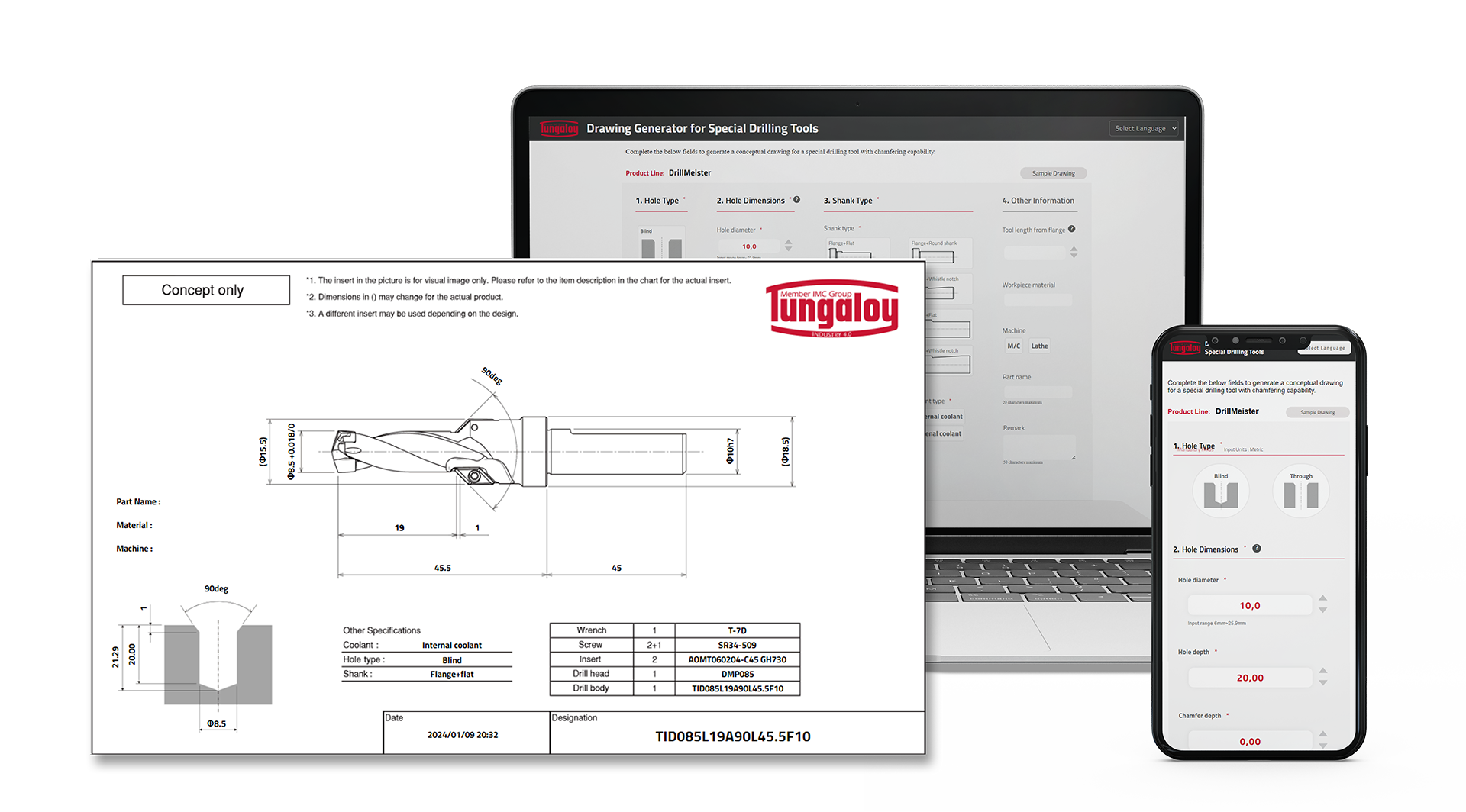

Explore the “Drawing System for Special Drilling Tools”! By inputting essential tool details, you can swiftly generate straightforward diagrams illustrating special drilling tools with chamfering functions.

The consistent use of new heads prevents performance decline and quality fluctuations often induced by re-grinding and re-coating. This approach guarantees stable, prolonged tool life and consistently high-quality machining results.

Decreasing chamfer width proves effective in curbing tool deflection and subsequently suppressing chatter. For instance, when handling larger chamfers (C5 or higher), pre-machining the workpiece into a multi-stage hole shape using a drill or counterbore cutter helps reduce machining allowances and dampens vibrations during chamfering.

Where Pocket cut constantly (and thus go faster than Adaptive Clearing), the extra time your mill gets to cool down with the Adaptive Clearing allows it to handle bigger steps. The bigger the pocket you are willing to mill, the more time you will save by using Adaptive Clearing instead of Pocket.

Choosing the right operations for a specific task can be overwhelming given the number of options available. Let’s start with a quick comparison of the basics.

R-Chamfering involves a process dedicated to curving corners, notably effective in mitigating the risk of injuries. This method excels in ensuring smoother, safer edges.

Chatter during chamfering arises from radial cutting resistance and tool deflection due to this resistance. Additionally, resonance vibrations leading to chatter may occur when the tool’s rotational speed aligns with its natural frequency. Employing tools with high rigidity minimizes deflection, elevates the tool’s natural frequency, and prevents synchronization between tool speed and natural frequency.

To set up a Face operation, start by selecting the tool and according Feed and Speed. In the second menu tab, select the contour of the face you want to mill flat.

TUNGALOY CORPORATION 11-1 Yoshima-Kogyodanchi, Iwaki, Fukushima, 970-1144 Japan Phone: +81-246-36-8501 Fax: +81-246-36-8542 CONTACT FORM >

Machining materials with burrs or sharp edges can swiftly damage tools. Chamfering in advance minimizes tool wear, prolonging tool life and ensuring more efficient machining processes.

Introducing an innovative solution for creating drawings of specialized drilling tools, which was previously a time-consuming process.

Just as for the contour operation, we’ll start by defining the end mill end preset we want to use. We will now select the pocket we want to mill out.

As for any operations, you have to start by selecting the end mill you are willing to use for this operation. In our example, we are going to choose an 8 mm flat end mill (from our End mill bundle) for which we will use the hard wood preset.

By averting stress concentration—focusing stress in specific areas—chamfering improves the fatigue strength of components. Stress concentration refers to the accumulation of stress in particular zones, while fatigue strength measures a material’s resilience against repeated stress cycles.

Mekanika is a Belgian startup based in Brussels whose ambition is to make local production more accessible. We produce desktop machines for screen printing and CNC milling, which have been recognized for their quality and ease of use, with open source plans allowing makers to adapt their tools to their specific needs.

Utilize an indexable chamfering tool equipped with a chip breaker to curb chip extension and entanglement with the tool.

Sometimes, reducing the number of inserts on the tool, such as transitioning from 4 to 2 inserts (or even down to 1 insert in specific cases) for indexable cutters, can help in damping chatter.

For example, if you look at the four corners of a smartphone, you will notice that the corners are diagonal, rounded, and chamfered to prevent pain.

DrillMeister’s special chamfer employs inserts with chip breakers that effectively manage chips during chamfering, preventing elongation and entanglement, thus improving chip control.

In the fourth tab, you should only edit the Multiple passes - Maximum Roughing stepdown value and the Stock to Leave values.

Thread chamfering is a meticulous process that delicately trims corners to an imperceptible degree. It serves a unique purpose, ideal in cases where neither C-Chamfering nor R-Chamfering is required. Instead, the focus remains on eliminating burrs to an extent that escapes visual detection.

In this article, we’ll give you a quick overview of the main CNC milling operations Autodesk Fusion360 offers, with the goal to help you identify the best ones for your next project.

We would recommend using helix’s for all materials with the angle set to the values presented before. The values you should change here are :

To mill pockets, you have to choose between 2 different operations (as explained before) : Pocket and Adaptive Clearing. Please refer to the previous section to learn more about these two operations.

During chamfering, encountering chatter represents a notable issue. This phenomenon, known as chattering, becomes particularly problematic when chamfering around holes using a punching technique. A common occurrence is observed when executing a C chamfer with a 45-degree angle, resulting in a tool edge aligned at the same angle. This alignment escalates the cutting force, directing deflection towards the tool diameter.

The Stepover value is what defines the distance between two toolpath lines. The smaller, the more precise your 3D texture will be. But the longer it is going to take to execute the operation… Usually, a Stepover of 0.3 mm gives good results while remaining fast enough. If it is just to rough out the profile of your model, a Stepover of 0.5-1 mm will be faster and leave an ‘OK’ result.

DrillMeister’s specialized exchangeable head drills revolutionize machining by merging innovative design with practicality, resulting in heightened machining accuracy, efficiency, and cost-effectiveness.

Reducing rotation speed often resolves chatter, though this approach can impact machining efficiency and surface quality. Balancing these trade-offs and optimizing rotation speed effectively minimizes vibration.

These kinds of projects are often using a 3D Adaptive Clearing operation first (to rough out the stock), and a Scallop operation with a ball end mill next to refine the texture. The Scallop operation will make a 3D toolpath around a point and make the end mill travel all around the texture you are willing to mill to get rid of the rice field effect left by a 3D Adaptive Clearing operation.

If you are using clamps to secure your stock to the spoilerboard, we advise you not to change these values. If you’ve secured your stock using screws, you can change the value up to the ones shown in the figure below (not less).

Effective chip management is crucial to prevent the entanglement of chips that might otherwise lead to tool damage or workpiece impairment. Similarly to the occurrence of “Chatter in Chamfering Processes,” this issue often arises during continuous machining, especially when chamfering around holes.

The last tab is to tell Fusion360 how you want your end mill to enter and exit the stock. In general, we recommend using Ramps instead of Leads & Transitions.

Tungaloy´s main chamfering cutters, such as ECC and TungQuad, have a cutting edge design with a large rake angle that is optimized for chamfering.

There are no parameters to edit when using the Bore operation. Simply select the right tool, preset and the holes you want to bore out, As always, you can (optionally) edit the heights to encounter thick stock or long end mills. There is no need to define ways of going in and out the stock as the Bore operation will describe a helix when plunging into the material.

C-Chamfering represents a prevalent technique where edges are sliced at a precise 45° angle. Often, discussions surrounding “chamfering” primarily allude to this method. Practical directives such as “C1” are commonly employed in on-site procedures, indicating the removal of a 1mm width from the edge.

The tool’s overhang length and the drill’s distance from the chamfering edge remain constant with an exchangeable head drill. This maintains dimensional accuracy during machining, significantly reducing the risk of defective workpieces.

Milling flat surfaces is a one of the that huge asset a CNC milling machine can offer. Whether you want to use your CNC as a jointer, mill some engineering projects or just flatten your spoilerboard, the Face operation is the one you want to go for.

Chamfering serves more than just an aesthetic purpose; it yields numerous advantages, enhancing both product quality and functionality.

Chamfering is often used in cooking because cutting off the corners of vegetables prevents them from collapsing during cooking and allows the flavors to soak in more easily.

To engrave text, logo’s or any other 2D profile in your material, Fusion360 has an Engrave operation. You can learn more about how to use it in our Branding your project.

In scenarios involving larger chamfer widths (such as C2 or higher), the radial cutting force intensifies, significantly amplifying chatter due to tool deflection.

A CNC machine is not only used for 2D operations like cutting contours or making straight holes, it gives you the opportunity to mill 3D textured projects that would have been impossible to achieve by hand (see our Topographical map project).

Preliminary trick: by placing your mouse on the icon of an operation, Fusion360 opens a little help widget with a brief explanation of said operation.

Employ a strategic approach of “step” or “dwell machining” during the machining process to forcibly break up chips. “Dwell machining” involves a temporary pause in feed progress while the drill spindle continues to rotate, aiding in chip fragmentation.

The only difference in parameters compared with the Pocket operation is in the fourth menu tab. The Optimum Load should always be inferior to your mill’s radius (in our case, smaller than 4 mm). A higher value would cause the mill to heathen up more quickly, and a lower value would give it more time to cool down, but would also increase the milling time. The main advantage of Adaptive Clearing over Pocket is that you can increase the depth of cut. Where we used 3.5 mm for our cut depth when setting up the Pocket operation, we will now go up to 6 mm depth. Which will greatly decrease the milling time.

The chamfer width exhibits irregularity, attributed to tool deflection and chatter, varying based on the machined area and the hole’s phase. As a solution, the measures shown in the previous section”Chatter in Chamfering Processes” are also effective in this case.

We use cookies to provide improved experience on this website. You can learn more about our cookies and how we use them in our Cookie Policy.

Explore Tungaloy’s TungMeister line, featuring a diverse selection of exchangeable head tools designed for precise chamfering applications. These tools simplify tool replacement through their interchangeable heads. The TungMeister lineup includes three specialized head types—center drill, back chamfering, and R chamfering heads—ideal for both chamfering and spot drilling tasks, offering versatility to address specific machining needs.

Choosing between 2D or 3D operation is pretty straightforward: is the volume you want to mill a straight extruded shape, or is there any variance in the extrusion (chamfers, filets, bumps, gaps, slots, etc…)?

Opt for blades featuring substantial rake and helix angles alongside sharp cutting edges. This mitigates the radial cutting force, a primary contributor to chatter during chamfering.

The fifth menu tab of this operation is quite similar to the one we have for the Contour operation, except that we have multiple options for the Ramps.

Chamfered parts contribute to a uniform finish when painted or plated, resulting in a high-quality appearance that enhances the overall aesthetic appeal.

The Bore operation with plunge in Z while making a helix in XY. This means that you can “drill out” holes that are up to twice the diameter of your end mill. It is also much faster than using a pocket operation for these holes, and will help chips extract from the hole you are drilling out.

Similarly than for the Contour operation, we can optionally adjust the heights in the third menu tab. Also here, the fourth menu tab is only used to set step depth and stock-to-leave’s.

In the second tab, select the contour you want to mill. If this is an exterior contour, we have to use tabs so that, once the mill reaches the bottom of our piece, the whole body doesn’t come loose (which might be very dangerous).

The third menu tab is used to define planes above the model for the end mill to travel when it is not cutting. Editing this tab is optional, but you will eventually have to change these values when using long end mills or when milling really thick stock.

When it comes to milling pockets (basically large holes), you have 2 options: the Pocket operation or the Adaptive Clearing operation.

Contour is used to make 2D cuts to free a piece from its stock or to make slots inside the piece. It can also be used to clean the inner edges after an Adaptive Clearing or Pocket operation. Think of it as a release cut you would do with a jig saw.

Tungaloy highly recommends DrillMeister, an exchangeable head tool featuring a chamfer body that significantly enhances chamfering efficiency.

The Drill operation will use fixed XY coordinates and plunge in Z. This means that you can only drill out a hole that is the exact same diameter as the end mill you are using, and that dust extraction is not very good.

0086-813-8127573

0086-813-8127573