Best End Mill Bits - mill end bits

Foundation for Finishing: Roughing provides a solid base for finishing, ensuring that the latter can proceed smoothly, improving accuracy and surface quality.

Pipe Ø (OD) 75mm - 1000mm (3- 40) Wall thickness 1,5mm (0.06), 6mm (0.23) seam. Cuts the following pipe materials, Thin wall steel, aluminum, and stainless ventilation pipes.

In the field of CNC machining and parts manufacturing, roughing and finishing are two critical stages that together determine the final quality and performance of a part. Roughing focuses on quickly removing excess material to set the stage for finishing, which aims to enhance the dimensional accuracy, surface quality, and overall performance of the part. This article will delve into the differences between roughing and finishing and provide a CNC machining guide to help experts and practitioners improve manufacturing efficiency and product quality.

Exactpipe cut 360

In the field of CNC machining and parts manufacturing, roughing and finishing are two critical stages that together determine the final quality and performance of a part. Roughing focuses on quickly removing excess material to set the stage for finishing, which aims to enhance the dimensional accuracy, surface quality, and overall performance of the part. This article will delve into the differences between roughing and finishing and provide a CNC machining guide to help experts and practitioners improve manufacturing efficiency and product quality.

Rough turning and finish turning are two distinct stages in turning operations. Rough turning primarily aims to quickly remove excess material and shape the workpiece roughly, while finish turning further improves dimensional accuracy and surface quality. They differ significantly in cutting parameters, tool selection, and machining goals.

Finishing: Coolant plays a more crucial role in finishing, helping to reduce cutting temperatures, flush away chips, and minimize friction and heat build-up in the cutting zone, ensuring the quality of the machined surface.

In the field of CNC machining and parts manufacturing, roughing and finishing are two critical stages that together determine the final quality and performance of a part. Roughing focuses on quickly removing excess material to set the stage for finishing, which aims to enhance the dimensional accuracy, surface quality, and overall performance of the part. This article will delve into the differences between roughing and finishing and provide a CNC machining guide to help experts and practitioners improve manufacturing efficiency and product quality.

Voltage / Current 110V, 120V / 15A Available also in Voltage / Power 230V / 2500W Special Order No-Load speed I=1900 r/min, II=2885 r/min Blade diameter 165mm (6.50) Mounting bore 62mm (2.44) Weight 17,5 kg (38,6 lbs) Range of use 75mm 360mm (3- 14) Max. pipe wall 20mm (0.8) steel / 230V 12mm (0.5") steel / 120V 50mm (2) plastics Electronically unit Blade speed pre-selection, automatic fuse, soft start, torque control Speed pre-selection I = Stainless steel and acid-resistant steel, II = all other materials Loading capacity of supports 465 kg, 1025 lb (3 supports)

Exactpipe cutter 170E

In the field of CNC machining and parts manufacturing, roughing and finishing are two critical stages that together determine the final quality and performance of a part. Roughing focuses on quickly removing excess material to set the stage for finishing, which aims to enhance the dimensional accuracy, surface quality, and overall performance of the part. This article will delve into the differences between roughing and finishing and provide a CNC machining guide to help experts and practitioners improve manufacturing efficiency and product quality.

Warranty terms If the Exact PipeCut Saw becomes unusable due to material or manufacturing defects within the Warranty Term or *Extended Warranty Term at our discretion we will repair the Exact PipeCut Saw or supply an entirely new or factory reconditioned Exact PipeCut Saw at our discretion, at no charge. Warranty Term / *Extended Warranty Term The Exact Tools Warranty Term is for 12 months from date of purchase. *By registering on-line you will receive an additional 12 months Warranty Term for FREE. Warranty registration must be completed within one month of purchase.

TCT 140 Saw Blade will also fit Rothenberger PipeCut 200U & Rothenberger PipeCut Turbo 250 TCT 165 Saw Blade will also fit Rothenberger PipeCut Turbo 400

Finishing plays a crucial role in enhancing part quality, including high dimensional accuracy, improved aesthetics, increased durability, better surface quality, and extended product life.

Extended Tool Life: Although roughing subjects the tools to greater cutting forces, the right choice of cutting parameters and tool materials can effectively prolong tool life.

Roughing and finishing differ significantly in purpose, material removal rate, feed rate and depth of cut, surface roughness/finish, dimensional accuracy and tolerance, tool type, and coolant usage.

Increased Durability: High-precision machined surfaces reduce friction and wear, improving the part's durability and lifespan.

ExactP1000

Technical details Voltage 110 - 120 V / 50 - 60 Hz Power 1200 W Voltage 2110 - 120 V / 50 - 60 Hz (Special Order) R.P.M. 1600 - 3500 r/m Intermittent S3 25 % operation Blade diameter 140 mm Blade center bore 62 mm Weight 5,7 kg Range of use 15 - 170 mm Max pipe wall thickness 8 mm for steel or 14 mm for plastics. Set Includes: PIPECUT 170 E Pipe supports set One TCT disc HM 140 x 62 (universal)

Technical details Power 4.6 HP / 3,4 KW Required Air pressure 6 bar / 90 psi Blade diameter 180mm (7.09) Mounting bore 62mm (2.44) Weight 26,7kg (59 lbs) Range of use Ø 110 - 360 mm (4 - 15) Set Includes: PipeCut AIR 360 Wrench with push stick A small funnel to fit into the oil inlet hole 5mm Allen Key for the oil port

CERMET V155 In Exact PipeCut V1000 we use a specially designed Cermet V155 blade that has 58 extremely durable ceramic alloy tips. It is designed for cutting thin sheet materials such as spiral ducts. Cermet blades can be sharpened a couple of times so they will become like new.

Voltage / Power 230V / 1010W (Special Order) Voltage / Current 110V, 120V / 8.4A No-Load speed 4000 r/min Blade diameter 155mm (6.1) Mounting bore 65mm (2.55) Weight 6,0kg (13 lbs) Range of use Ø 75mm - 1000mm (3- 40) Max. pipe wall 1,5mm (0.06), 6mm (0.23) seam.

Pipe Ø (OD) 15 - 170 mm (0.6 - 6.7) Wall thickness 8 mm (0.31) st, 14 mm (0.55) plastic Cuts the following pipe materials Steel, copper, cast iron, stainless steel, acid-resistant steel, multi-layered materials and all plastics Loading capacity of supports 418 lb

Professional Pipe Beveller for on-site welding applications Continuous good results for on-site pipe beveling applications with Exacts PipeBevel 220E/360E you can easily make fast and accurate welding bevels to pipes in a variety of materials. The user interface of the machine is similar to Exact pipe saws, which makes it easy for the operator to adapt after cutting the pipe with any Exact pipe saw. The cutting head of the beveller has 3 cutting tips, each of them having 4 cutting edges to rotate once becoming blunt, so it is economical to use.

Dimensional Accuracy: Strictly control the dimensional accuracy during machining to ensure the part meets design specifications.

Material Type: Understand the physical and chemical properties of the workpiece material to choose suitable cutting methods and tool materials.

Common challenges in CNC roughing include rapid tool wear, significant workpiece thermal deformation, and chip handling difficulties. To address these challenges, select appropriate tools, optimize cutting parameters, and enhance coolant and chip removal to reduce cutting forces and heat accumulation, improving machining stability and efficiency.

ExactPipeCut 460 Pro Series

Improved Aesthetics: The surface of finished parts is smooth, with no noticeable tool marks or burrs, enhancing the part's appearance.

In the field of CNC machining and parts manufacturing, roughing and finishing are two critical stages that together determine the final quality and performance of a part. Roughing focuses on quickly removing excess material to set the stage for finishing, which aims to enhance the dimensional accuracy, surface quality, and overall performance of the part. This article will delve into the differences between roughing and finishing and provide a CNC machining guide to help experts and practitioners improve manufacturing efficiency and product quality.

Tool Selection: Choose the right type and specification of tools based on the machining material and requirements, ensuring the tool's strength and wear resistance.

In the field of CNC machining and parts manufacturing, roughing and finishing are two critical stages that together determine the final quality and performance of a part. Roughing focuses on quickly removing excess material to set the stage for finishing, which aims to enhance the dimensional accuracy, surface quality, and overall performance of the part. This article will delve into the differences between roughing and finishing and provide a CNC machining guide to help experts and practitioners improve manufacturing efficiency and product quality.

In the field of CNC machining and parts manufacturing, roughing and finishing are two critical stages that together determine the final quality and performance of a part. Roughing focuses on quickly removing excess material to set the stage for finishing, which aims to enhance the dimensional accuracy, surface quality, and overall performance of the part. This article will delve into the differences between roughing and finishing and provide a CNC machining guide to help experts and practitioners improve manufacturing efficiency and product quality.

220E Voltage / Power / Current 220-240 V / 1400W / 6.1 A No-Load speed 7000 - 10500 r/min Blade holder diameter 48 mm (1.89) Different bevel angles 30° | 37,5° | 45° Weight 6,7kg (14.8 lbs) Range of use Ø 25mm 220mm (0.98- 8.6) Max. pipe wall 10mm (0.39) st

Machine Type and Control Software: Use machines and control software suitable for roughing to ensure machine stability and machining accuracy.

High Dimensional Accuracy: Finishing ensures that the dimensional accuracy of the part meets design requirements through precise control of cutting parameters and tool paths.

Part Application: Understand the specific application environment and requirements of the part to take appropriate measures during machining to meet performance needs.

Extended Product Life: By enhancing the overall performance and longevity of the part, finishing helps reduce the frequency of product replacement and maintenance costs.

TCT BLADES Blade with tungsten carbide tips for general use. Suitable for cutting steel, copper, aluminum and plastics. TCT blades can be sharpened a couple of times.

Finishing typically includes three types: grinding, polishing, and lapping. Grinding involves cutting the workpiece surface with an abrasive tool; polishing smooths the surface using a polishing tool and compound; lapping involves fine processing with a lapping tool and compound to achieve higher surface quality. These methods have unique features and applications, and the appropriate finishing method can be chosen based on specific needs.

Roughing: While coolant is also important in roughing, its primary purpose is to reduce tool wear and workpiece thermal deformation due to the high cutting speed and material removal.

ExactPipe Cutter 220E

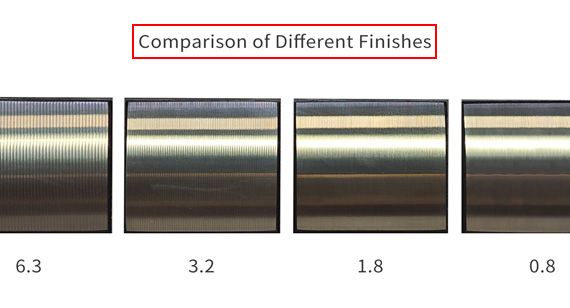

Better Surface Quality: Finishing significantly reduces surface roughness, improving the surface quality to meet specific application needs.

In the field of CNC machining and parts manufacturing, roughing and finishing are two critical stages that together determine the final quality and performance of a part. Roughing focuses on quickly removing excess material to set the stage for finishing, which aims to enhance the dimensional accuracy, surface quality, and overall performance of the part. This article will delve into the differences between roughing and finishing and provide a CNC machining guide to help experts and practitioners improve manufacturing efficiency and product quality.

The finishing stage requires greater attention to factors such as dimensional accuracy, part application, post-processing, and cost.

Simplifying Complex Cuts: For complex-shaped workpieces, roughing can create a basic outline, reducing the difficulty of subsequent finishing operations.

Pipe Ø (OD) 110 - 360 mm (4 - 15) Wall thickness 45mm (1.8) cast iron 45mm (1.8) plastics Pneumatic PipeCut AIR 360 A new pneumatic pipe saw In Exact family. It is designed mainly for to be used to cut assembled pipes in a ditch, but it can be also used on the pipe supports like any other Exact pipe saw.

To order from CMS Industrial Equipment Corporation, simply shop online, or fax your order to the number below. The staff at our US offices can also help you make the best choice for all of your pipe cutting needs. Warranty terms If the Exact PipeCut Saw becomes unusable due to material or manufacturing defects within the Warranty Term or *Extended Warranty Term at our discretion we will repair the Exact PipeCut Saw or supply an entirely new or factory reconditioned Exact PipeCut Saw at our discretion, at no charge. Warranty Term / *Extended Warranty Term The Exact Tools Warranty Term is for 12 months from date of purchase. *By registering on-line you will receive an additional 12 months Warranty Term for FREE. Warranty registration must be completed within one month of purchase.

CNC roughing generates significant cutting forces and vibrations, placing high demands on machine rigidity and stability. If the machine is poorly designed or inadequately maintained, prolonged roughing operations can lead to accelerated wear, reduced precision, and shortened machine life. Therefore, machine selection should consider its capacity to handle roughing, and proper maintenance is essential.

Heat and Coolant: Monitor heat generation and coolant usage during machining, adjusting cutting parameters and cooling methods as necessary.

Roughing in CNC machining offers several benefits, including rapid material removal, extended tool life, laying the groundwork for finishing, increased efficiency, and simplifying complex cuts.

Roughing and finishing both contribute to improving the performance of parts in various aspects, including hardness, adhesion, weldability, electrical conductivity, smoothness, corrosion resistance, and wear resistance. Roughing sets the foundation by quickly removing material and easing the load for subsequent operations, while finishing refines the surface and dimensional accuracy, enhancing the overall performance and lifespan of the part.

Cuts the following pipe materials Steel, copper, cast iron, stainless steel, acid-resistant steel, multi-layered materials and all plastics Loading capacity of supports 692 lb. THE MOST ADVANCED PIPE CUTTING SYSTEM EVER MADE! Much stronger 2500W 230V / 2200W 120V motor. Electronics protecting the motor from overload and traffic lights guiding the operator. Laser indicator for precise cutting. Improved adjustment mechanism for straight cutting. Professional quality - Made in EU. Cuts steel pipes with wall thickness up to 20 / 12 mm.

Post-Processing: Perform appropriate post-processing on machined parts, such as deburring, cleaning, and surface treatment, to improve surface quality and overall performance.

It is also possible to make different tailored bevel angles if required. There is also a stopper feature, that enables the operator to make similar additional bevels to the same pipe O/D.

Exactcut software

VMT CNC Machining Factory offers one-stop CNC machining services, including design consultation, material selection, roughing, finishing, and final inspection. With advanced CNC equipment and experienced technicians, we provide high-quality custom CNC machining services to meet diverse customer needs. Whether for simple part machining or complex component manufacturing, we can fulfill various customer requirements.

Much stronger 2500W 230V / 2200W 120V motor. Electronics protecting the motor from overload and traffic lights guiding the operator. Laser indicator for precise cutting. Improved adjustment mechanism for straight cutting. Professional quality - Made in EU. Cuts steel pipes with wall thickness up to 20 / 12 mm.

Pipe Ø (OD) 220E Pipe Ø (OD) 360E 25mm 220mm (0.98- 8.6) 110mm 360mm (4.33- 14.17) Wall thickness 10mm (0.39) st Cuts the following pipe materials Steel, stainless steel, aluminium

Pipe Ø (OD) 75mm 360mm (3- 14)Wall thickness 8mm (0.31) steel, 25mm (0.98) plCuts the following pipe materials Steel, copper, cast iron, stainless steel, acid-resistant steel, multi-layered materials and all plastics

Watch a short video click here Exact PIPECUT® 170 E Portable pipe cutting system Ø 0.6" - 6.70" Pipe Ø (OD) 15 - 170 mm (0.6 - 6.7) Wall thickness 8 mm (0.31) st, 14 mm (0.55) plastic Cuts the following pipe materials Steel, copper, cast iron, stainless steel, acid-resistant steel, multi-layered materials and all plastics Loading capacity of supports 418 lb Most lightweight (5,7 kg) pipe cutting system Range of use: 15 170 mm (0.6" - 6.7") Max pipe wall thickness: 8 mm for steel or 14 mm for plastics Technical details Voltage 110 - 120 V / 50 - 60 Hz Power 1200 W Voltage 2110 - 120 V / 50 - 60 Hz (Special Order) R.P.M. 1600 - 3500 r/m Intermittent S3 25 % operation Blade diameter 140 mm Blade center bore 62 mm Weight 5,7 kg Range of use 15 - 170 mm Max pipe wall thickness 8 mm for steel or 14 mm for plastics. Set Includes: PIPECUT 170 E Pipe supports set One TCT disc HM 140 x 62 (universal) Description lbs. No. $Price Add to Cart Exact PIPECUT® 170 E 25.00 7010463US $1,758.00 Buy now Exact PIPECUT® 280 Pro Series Portable pipe cutting system Ø 2" - 11" Pipe Ø (OD) 40mm - 280mm (2- 11) 20mm (0.8) steel / 230V 12mm (0.5") steel / 120V 45mm (2) plastics Cuts the following pipe materials Steel, copper, cast iron, stainless steel, acid-resistant steel, multi-layered materials and all plastics Loading capacity of supports 692 lb. THE MOST ADVANCED PIPE CUTTING SYSTEM EVER MADE! Much stronger 2500W 230V / 2200W 120V motor. Electronics protecting the motor from overload and traffic lights guiding the operator. Laser indicator for precise cutting. Improved adjustment mechanism for straight cutting. Professional quality - Made in EU. Cuts steel pipes with wall thickness up to 20 / 12 mm. Technical details Voltage / Current 110V, 120V / 15A Available also in Voltage / Power 230V / 2500W Special Order No-Load speed I=1900 r/min, II=2885 r/min Blade diameter 165mm (6.50) Mounting bore 62mm (2.44) Weight 15,5 kg (34,2 lbs) Range of use 50mm 280mm (2- 11) Max. pipe wall 20mm (0.8) steel / 230V 12mm (0.5") steel / 120V 45mm (2) plastics Electronical unit Blade speed preselection, automatic fuse, soft start, torque control Speed preselection I = Stainless steel and acid-resistant steel, II = all other materials Loading capacity of supports 465 kg, 1025 lb (3 supports) Set Includes: PipeCut Bag 3 Exact PipeCut 280 Pro Series pipe saw Pipe Support 280, 4pcs Operating instructions Hex socket key 5 mm and 2 mm fitted to the machine TCT 165 blade fitted to the machine DVD video disc including instructions Description lbs. No. $Price Add to Cart Exact PIPECUT® 280 Pro Series 115V 38.00 7010412US $3,583.00 Buy now Exact PIPECUT® 360 Pro Series Portable pipe cutting system Ø 3" - 14" Large single-speed universal pipe saw. It canbe used for cutting both steel and plastic pipes. The Pipecut 360 heavy duty design and construction plus the capacity to cut large diameter pipes make it the ideal all-around pipe cutting tool. Pipe Ø (OD) 75mm 360mm (3- 14)Wall thickness 8mm (0.31) steel, 25mm (0.98) plCuts the following pipe materials Steel, copper, cast iron, stainless steel, acid-resistant steel, multi-layered materials and all plastics Much stronger 2500W 230V / 2200W 120V motor. Electronics protecting the motor from overload and traffic lights guiding the operator. Laser indicator for precise cutting. Improved adjustment mechanism for straight cutting. Professional quality - Made in EU. Cuts steel pipes with wall thickness up to 20 / 12 mm. Technical details Voltage / Current 110V, 120V / 15A Available also in Voltage / Power 230V / 2500W Special Order No-Load speed I=1900 r/min, II=2885 r/min Blade diameter 165mm (6.50) Mounting bore 62mm (2.44) Weight 17,5 kg (38,6 lbs) Range of use 75mm 360mm (3- 14) Max. pipe wall 20mm (0.8) steel / 230V 12mm (0.5") steel / 120V 50mm (2) plastics Electronically unit Blade speed pre-selection, automatic fuse, soft start, torque control Speed pre-selection I = Stainless steel and acid-resistant steel, II = all other materials Loading capacity of supports 465 kg, 1025 lb (3 supports) PipeCut Bag 3 Exact PipeCut 360 Pro Series pipe saw Pipe Support 360 Double and 2x 360 Single and tool for changing blade in the bag. Operating instructions Hex socket key 5 mm and 2 mm fitted to the machine TCT 165 blade fitted to the machine DVD video disc including instructions Description lbs. No. $Price Add to Cart Exact PIPECUT® 360 Pro Series 115V 40.00 7010413US $3,996.90 Buy now Exact PIPECUT® V1000 Ventilation pipe saw Portable ventilation pipe saw Its a new era for spiral duct cutting. Exact PipeCut V1000 offers ease of use and a huge size range for cutting spiral ducts. The finished ends are straight and ready to be connected. As an option, we have special pipe supports for the V1000 that can hold spiral ducts from 3 40 (75mm-1000mm). Pipe Ø (OD) 75mm - 1000mm (3- 40) Wall thickness 1,5mm (0.06), 6mm (0.23) seam. Cuts the following pipe materials, Thin wall steel, aluminum, and stainless ventilation pipes. Technical details Voltage / Power 230V / 1010W (Special Order) Voltage / Current 110V, 120V / 8.4A No-Load speed 4000 r/min Blade diameter 155mm (6.1) Mounting bore 65mm (2.55) Weight 6,0kg (13 lbs) Range of use Ø 75mm - 1000mm (3- 40) Max. pipe wall 1,5mm (0.06), 6mm (0.23) seam. PipeCut Bag 1 Exact PipeCut V1000 pipe saw Operating instructions Hex socket key 5 mm fitted to the machine Cermet V155 blade fitted to the machine DVD video disc including instructions WATCH DEMO VIDEO HERE Description lbs. No. $Price Add to Cart Exact PIPECUT® V1000 SYSTEM 120V 20.00 7010402US $1,422.00 Buy now Blades CMS Industrial Equipment Company has a wide range of specially designed blades for Exact PipeCut saws. High quality cutting blades are designed for different purposes and for different PipeCut machines. With the correct blade you can achieve optimal cutting results. TCT 140 & TCT 165 CERMET 140 & CERMET 165 DIAMOND X140 & DIAMOND X165 TCT P150 (PLASTICS ONLY) CERMET V155 TCT BLADES Blade with tungsten carbide tips for general use. Suitable for cutting steel, copper, aluminum and plastics. TCT blades can be sharpened a couple of times. TCT 140 Saw Blade will also fit Rothenberger PipeCut 200U & Rothenberger PipeCut Turbo 250 TCT 165 Saw Blade will also fit Rothenberger PipeCut Turbo 400 Dimensions (mm) 140 x 62 x 1.8 x 1.4 x 46 For Materials Steel Copper Plastics Aluminum For Machine Types PC 170, 170E, 220E TCT 140 Price $84.00 7010486 TCT 140 $88.00 Buy now TCT 165 For Pipecut 360 Price $89.00 7010487 TCT 165 $93.00 Buy now CERMET BLADES Blade with ceramic alloy tips for heavy duty applications, especially for cutting stainless and acid proof steel. Cermet blades can be sharpened a couple of times. CERMET 140 Saw Blade will also fit Rothenberger PipeCut 200U & Rothenberger PipeCut Turbo 250 CERMET 165 Saw Blade will also fit Rothenberger PipeCut Turbo 400 Dimensions (mm) 140 x 62 x 1.8 x 1.4 x 46 For Materials Steel Stainless Copper Plastics Acid proof CERMET 140 Price $105.00 7010496 Cermet 140 $110.00 Buy now CERMET 165 For Pipecut 360 Price $120.00 7010497 CERMET 165 $148.00 Buy now DIAMOND X140 & DIAMOND X165 Diamond blade designed only to be used for cutting cast iron pipes. DIAMOND X140 Saw Blade will also fit Rothenberger PipeCut 200U & Rothenberger PipeCut Turbo 250 DIAMOND X165 Saw Blade will also fit Rothenberger PipeCut Turbo 400 Dimensions (mm) 140 x 62 x 2.0 x 1.8 For Materials Cast iron For Machine Types PC 170, 170E, 220E DIAMOND X140 Price $236.00 7010492 Diamond x140 $248.00 Buy now DIAMOND X165 For Pipecut 360 Price $257.00 7010493 Diamond X165 $270.00 Buy now TCT P-190 Blade with tungsten carbide tips only for cutting plastic pipes. TCT blades can be sharpened a couple of times so they will become like new. Dimensions (mm) 190 x 62 x 1.8 x 1.4 x 40 (mm) For Materials Plastics (PE, PP, PVC, etc.) For Machine Types P1000 TCT P-190 Price $63.00 7010489 TCT P-190 $93.00 Buy now CERMET V155 In Exact PipeCut V1000 we use a specially designed Cermet V155 blade that has 58 extremely durable ceramic alloy tips. It is designed for cutting thin sheet materials such as spiral ducts. Cermet blades can be sharpened a couple of times so they will become like new. Dimensions (mm) 155 x 65 x 1.6 x 1.4 x 58 (mm) For Materials Thin wall steel, aluminum and stainless ventilation pipes. For Machine Types PCV 1000 CV155 Price $120.00 7010498 Cermet V155 $126.00 Buy now Exact Ground-breaking Solutions for Pipe Cutting and Finishing The Exact system: innovations that render pipe handling effortless, accurate and fast Over the last ten years, Exact has developed a number of modern tools for pipe cutting, finishing and processing. Innovative products from Exact raise the pipe working efficiency to an entirely new level. The Exact system is suitable for all pipes and materials Exact pipe cutters are suitable for all kinds of pipe materials; a single machine allows cutting pipes of greatly differing sizes. Pipe cutting is significantly faster as compared to traditional methods. The resulting surfaces are precise and of uniform quality the pipes are ready for joining right away. Exact pipe cutters can be used almost anywhere, since in most countries they are approved for indoor use for example, as compared to angle grinders, the fire hazards are substantially lesser. Exact pipe cutters are easy to move around and effortless to use, for it is not necessary to support the device while cutting. Since the cutting is fast and does not require strength, the physical work strain is very low. The ergonomic design of Exact pipe cutters allows avoiding accidents at work and the related absences. Moreover, the risk of developing work strain-related maladies is reduced. Efficiency and user-friendliness benefit the entire company Quick and easy-to-use Exact pipe cutters significantly improve work efficiency. The results are of higher quality and achieved faster as compared to former methods. The Exact products are designed to be long-lived and easy to maintain. It is quite usual for pipe cutters commissioned ten years ago to still be in daily use. Everybody wins: the employees feel better at work, the work progress is accelerated, and improved productivity is good for company profits. Worlds best in product design 2013 In 2013, the Pipecut 220E, 280E, and 360E pipe cutters by Exact Tools won the internationally prestigious Red Dot Design award. The award is granted to technically advanced and operationally superior design, and the competition involved nearly 5,000 products from all over the world. Exact pipe cutters represent sustainable development: upon pipe processing, the tools power consumption is only 15% of that of an angle grinder, and all tool components are recyclable. Exact Tools better results with less work To order from CMS Industrial Equipment Corporation, simply shop online, or fax your order to the number below. The staff at our US offices can also help you make the best choice for all of your pipe cutting needs. Warranty terms If the Exact PipeCut Saw becomes unusable due to material or manufacturing defects within the Warranty Term or *Extended Warranty Term at our discretion we will repair the Exact PipeCut Saw or supply an entirely new or factory reconditioned Exact PipeCut Saw at our discretion, at no charge. Warranty Term / *Extended Warranty Term The Exact Tools Warranty Term is for 12 months from date of purchase. *By registering on-line you will receive an additional 12 months Warranty Term for FREE. Warranty registration must be completed within one month of purchase. Exact Pipecut and PipeBevel Home Exact PipeCut and Exact PipeBevel Systems All content © Copyright 2024 CMS Industrial Equipment Company google5085db38241e0936.html

Technical details Voltage / Current 110V, 120V / 15A Available also in Voltage / Power 230V / 2500W Special Order No-Load speed I=1900 r/min, II=2885 r/min Blade diameter 165mm (6.50) Mounting bore 62mm (2.44) Weight 15,5 kg (34,2 lbs) Range of use 50mm 280mm (2- 11) Max. pipe wall 20mm (0.8) steel / 230V 12mm (0.5") steel / 120V 45mm (2) plastics Electronical unit Blade speed preselection, automatic fuse, soft start, torque control Speed preselection I = Stainless steel and acid-resistant steel, II = all other materials Loading capacity of supports 465 kg, 1025 lb (3 supports) Set Includes: PipeCut Bag 3 Exact PipeCut 280 Pro Series pipe saw Pipe Support 280, 4pcs Operating instructions Hex socket key 5 mm and 2 mm fitted to the machine TCT 165 blade fitted to the machine DVD video disc including instructions

Roughing is the initial stage in the machining process, primarily aimed at quickly removing a significant amount of material from the workpiece to bring it closer to its final shape. This stage typically employs larger cutting depths and feed rates to boost machining efficiency. Precision and surface quality are not the main concerns during roughing; instead, the focus is on reducing the material bulk to prepare for the finishing stage.

TCT P-190 Blade with tungsten carbide tips only for cutting plastic pipes. TCT blades can be sharpened a couple of times so they will become like new.

Workpiece Clamping: Ensure the workpiece is securely clamped during machining to prevent errors due to movement or vibration.

Finishing: Enhances the dimensional accuracy, surface finish, and overall performance of the workpiece to meet design requirements.

DIAMOND X140 Saw Blade will also fit Rothenberger PipeCut 200U & Rothenberger PipeCut Turbo 250 DIAMOND X165 Saw Blade will also fit Rothenberger PipeCut Turbo 400

Machining Parameters: Set cutting speed, feed rate, and depth of cut appropriately to balance machining efficiency and tool life.

Material Removal Rate is a key indicator of roughing efficiency. A high MRR means that a large amount of material can be removed quickly, reducing machining time and increasing production efficiency. In CNC roughing, it is crucial to set cutting parameters appropriately to achieve a high MRR.

In the field of CNC machining and parts manufacturing, roughing and finishing are two critical stages that together determine the final quality and performance of a part. Roughing focuses on quickly removing excess material to set the stage for finishing, which aims to enhance the dimensional accuracy, surface quality, and overall performance of the part. This article will delve into the differences between roughing and finishing and provide a CNC machining guide to help experts and practitioners improve manufacturing efficiency and product quality.

Exakt saw

Roughing requires special attention to factors such as material type, tool selection, machining parameters, machine type and control software, heat and coolant, and workpiece clamping.

ExactPipe Rollers

Its a new era for spiral duct cutting. Exact PipeCut V1000 offers ease of use and a huge size range for cutting spiral ducts. The finished ends are straight and ready to be connected. As an option, we have special pipe supports for the V1000 that can hold spiral ducts from 3 40 (75mm-1000mm).

Roughing and finishing are indispensable stages in CNC machining, together determining the final quality and performance of a part. By appropriately sequencing operations and choosing suitable machining methods, manufacturing efficiency and product quality can be significantly improved. Attention to details and considerations during machining is also essential to ensuring successful outcomes. VMT CNC machining services are committed to providing professional, efficient, and reliable CNC machining solutions, helping customers stand out in a competitive market.

Most lightweight (5,7 kg) pipe cutting system Range of use: 15 170 mm (0.6" - 6.7") Max pipe wall thickness: 8 mm for steel or 14 mm for plastics

Rapid Material Removal: Roughing employs large cutting depths and feed rates to remove substantial material quickly, significantly boosting machining efficiency.

PipeCut Bag 3 Exact PipeCut 360 Pro Series pipe saw Pipe Support 360 Double and 2x 360 Single and tool for changing blade in the bag. Operating instructions Hex socket key 5 mm and 2 mm fitted to the machine TCT 165 blade fitted to the machine DVD video disc including instructions

Upload Your Files or Contact inquiry@vimetal.com.cn to Get Instant Quote (Please attach 2D CAD drawings and 3D CAD models in any format including STEP, IGES, DWG, PDF, STL, ZIP, etc.).

Large single-speed universal pipe saw. It canbe used for cutting both steel and plastic pipes. The Pipecut 360 heavy duty design and construction plus the capacity to cut large diameter pipes make it the ideal all-around pipe cutting tool.

In the field of CNC machining and parts manufacturing, roughing and finishing are two critical stages that together determine the final quality and performance of a part. Roughing focuses on quickly removing excess material to set the stage for finishing, which aims to enhance the dimensional accuracy, surface quality, and overall performance of the part. This article will delve into the differences between roughing and finishing and provide a CNC machining guide to help experts and practitioners improve manufacturing efficiency and product quality.

In the field of CNC machining and parts manufacturing, roughing and finishing are two critical stages that together determine the final quality and performance of a part. Roughing focuses on quickly removing excess material to set the stage for finishing, which aims to enhance the dimensional accuracy, surface quality, and overall performance of the part. This article will delve into the differences between roughing and finishing and provide a CNC machining guide to help experts and practitioners improve manufacturing efficiency and product quality.

PipeCut Bag 1 Exact PipeCut V1000 pipe saw Operating instructions Hex socket key 5 mm fitted to the machine Cermet V155 blade fitted to the machine DVD video disc including instructions

Increased Efficiency: Rapid material removal reduces machining time, increases production efficiency, and lowers production costs.

Finishing is the advanced stage in machining, designed to enhance the dimensional accuracy, surface finish, and overall performance of the workpiece. During this stage, the cutting depth and feed rate are significantly reduced, while cutting speed is relatively high, ensuring a high-quality machined surface. Finishing not only focuses on the geometric dimensions of the part but also on surface roughness, tolerance control, and aesthetics to meet design specifications and application requirements.

CERMET BLADES Blade with ceramic alloy tips for heavy duty applications, especially for cutting stainless and acid proof steel. Cermet blades can be sharpened a couple of times.

360E Voltage / Power / Current 220-240 V / 1400W / 6.1 A No-Load speed 7000 - 10500 r/min Blade holder diameter 48 mm (1.89) Different bevel angles 30° | 37,5° | 45° Weight 11,2kg (24.7 lbs) Range of use Ø 110mm 360mm (4.33- 14.17) Max. pipe wall 10mm (0.39) st

CERMET 140 Saw Blade will also fit Rothenberger PipeCut 200U & Rothenberger PipeCut Turbo 250 CERMET 165 Saw Blade will also fit Rothenberger PipeCut Turbo 400

0086-813-8127573

0086-813-8127573